Full-automatic intelligent hydrodynamic viscosity measurement device and method

A liquid power and measurement device technology, applied in the field of experimental instruments, can solve problems such as low work efficiency, heavy main machine weight, and difficult cleaning of pipelines, so as to reduce the degree of wear and tear of hand washing, meet the requirements of environmental conditions, and avoid spillover accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

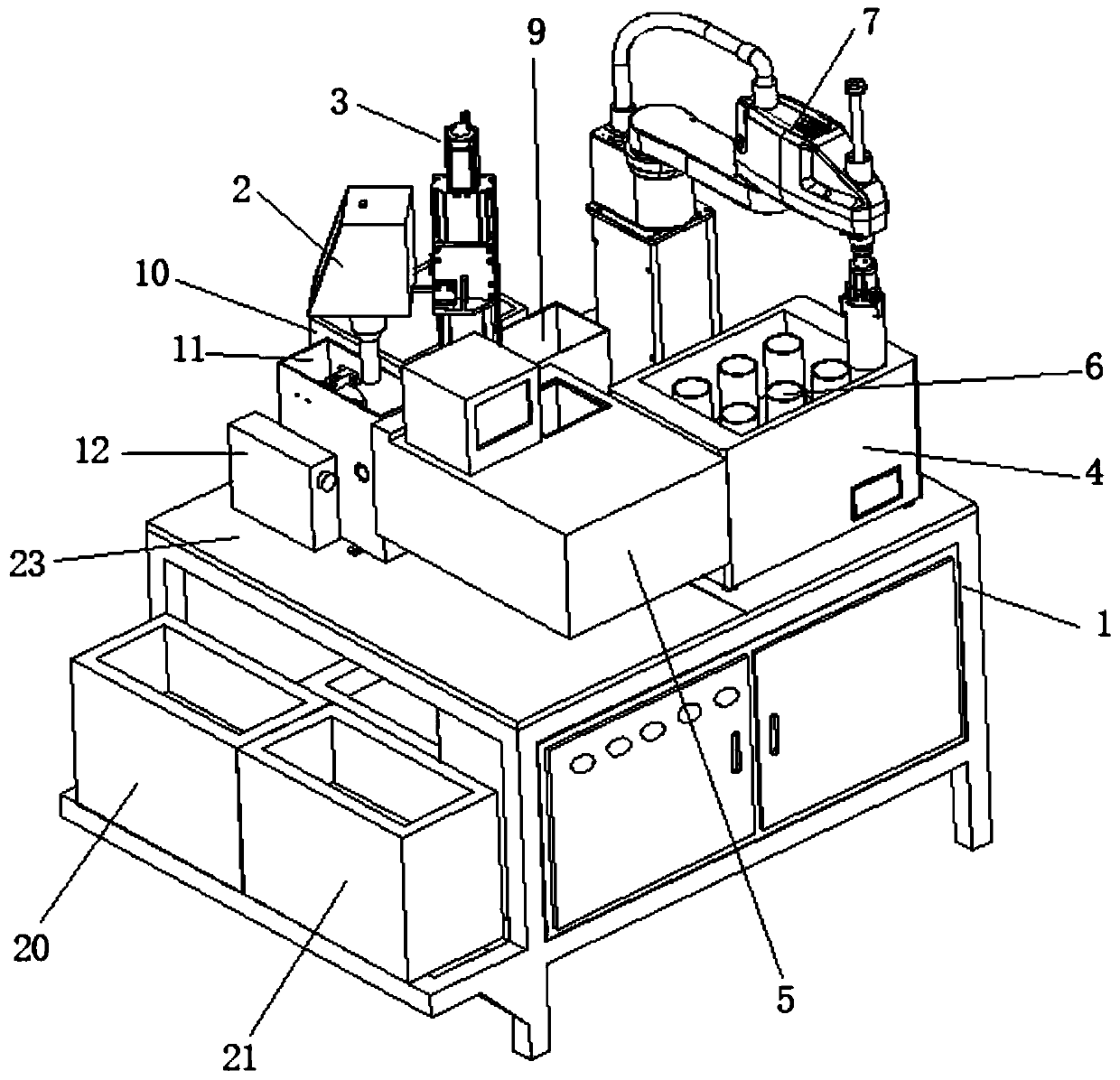

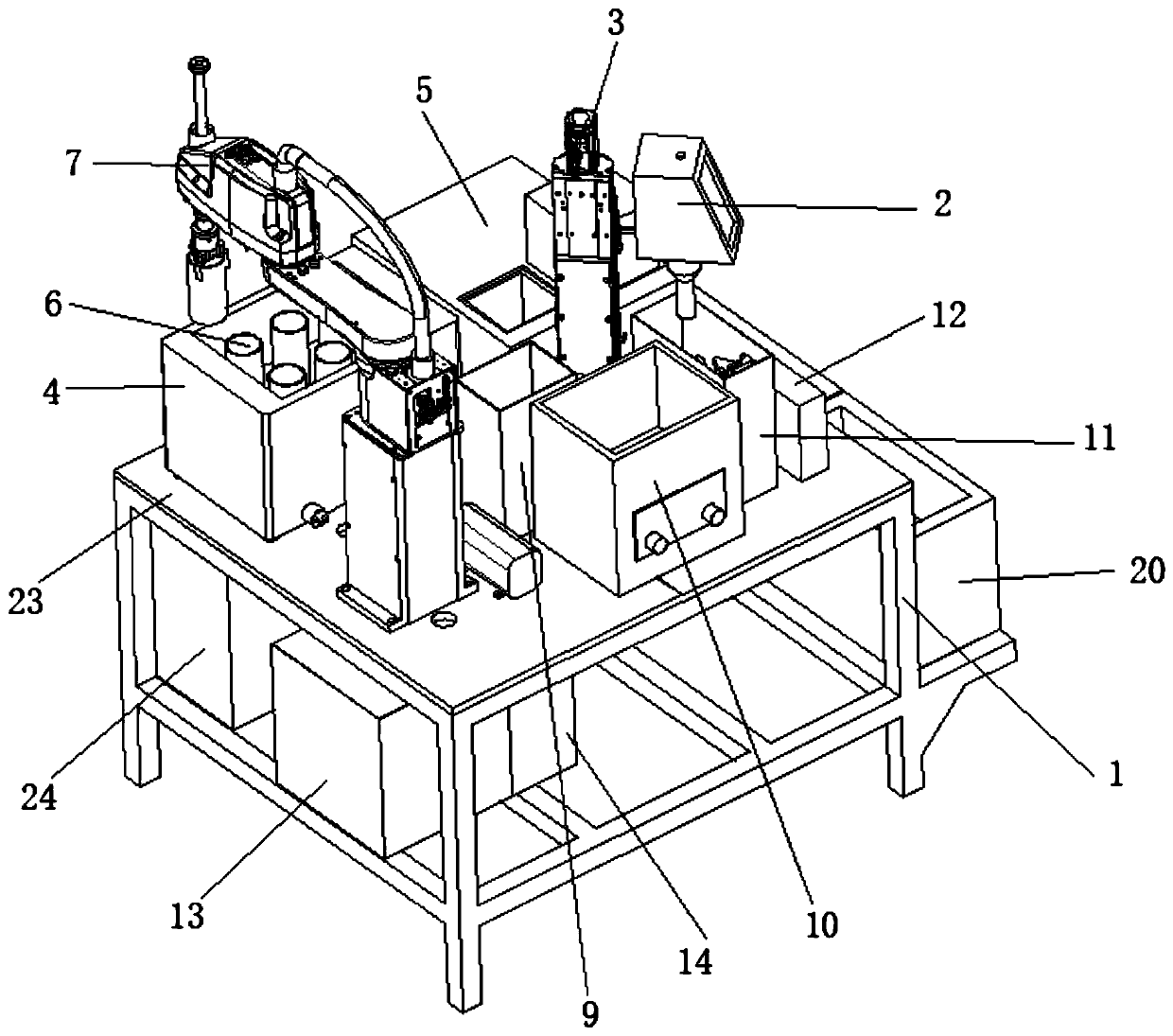

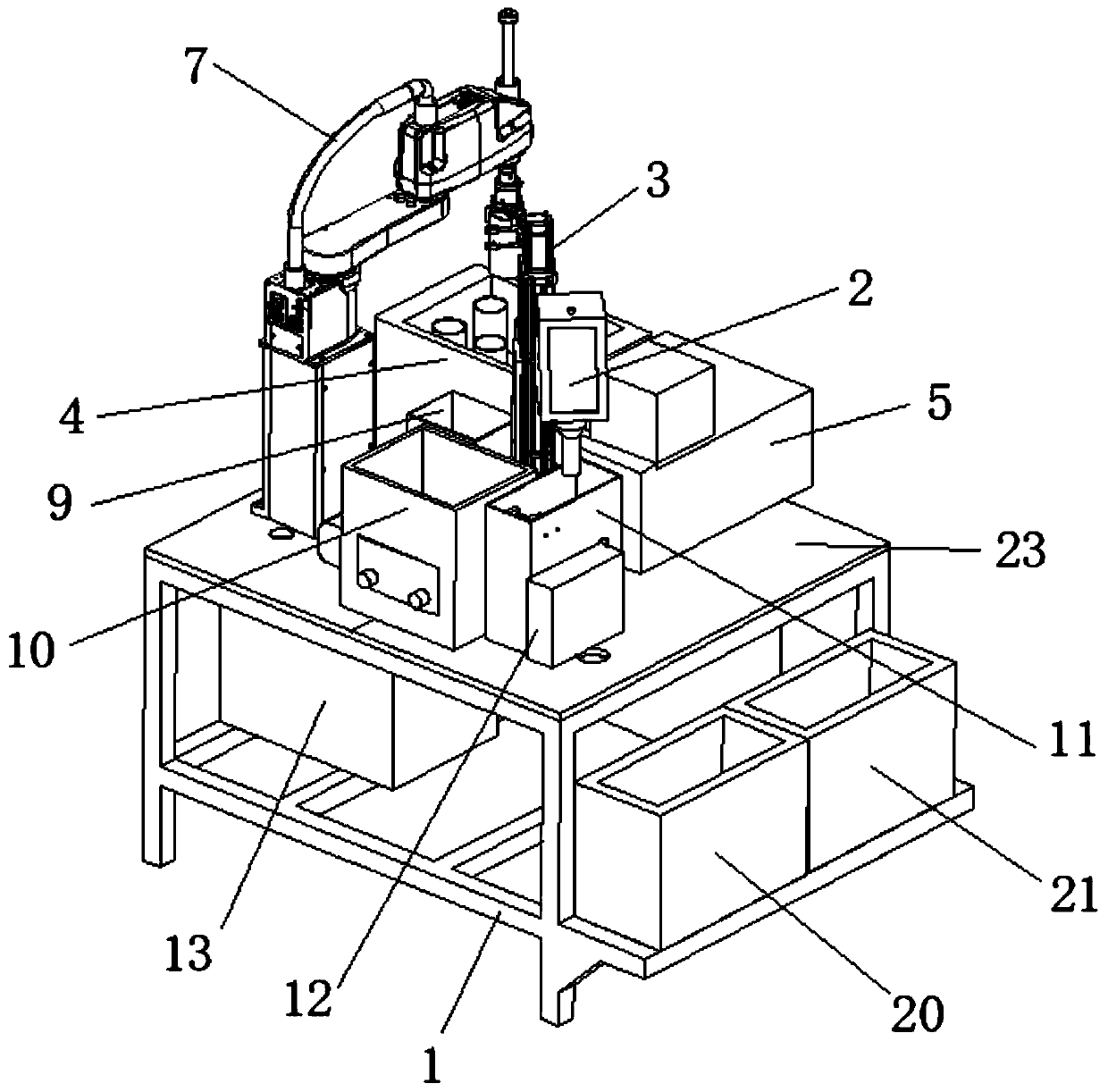

[0053] The invention provides a fully automatic intelligent liquid dynamic viscosity measuring device, which has the temperature control function of autonomous identification and temperature adjustment, the delivery function of grasping, releasing, lifting, translation, rotation and other multi-angle moving sample cups, lifting, There are five functional systems including the movement positioning adjustment function of the translational and rotational viscometer, the cleaning and drying function of the cleaning and drying rotor, and the calibration and detection function of collecting and analyzing data. The five major systems coordinate linkage and organic control through motion software or detection software. Specific as figure 1 As shown, it includes a frame and a viscosity measurement unit arranged on the frame, a sample transfer unit, a constant temperature water bath unit, a cleaning unit, a drying unit, a control unit 13 and a data acquisition and analysis unit;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com