Rotational viscometer

A rotational viscometer, rotational speed technology, applied in the direction of flow characteristics, measuring devices, instruments, etc., can solve the problems of distorted, complicated, and limited measurement range of measurement results, and achieve the effect of eliminating distorted, compact and sensitive structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

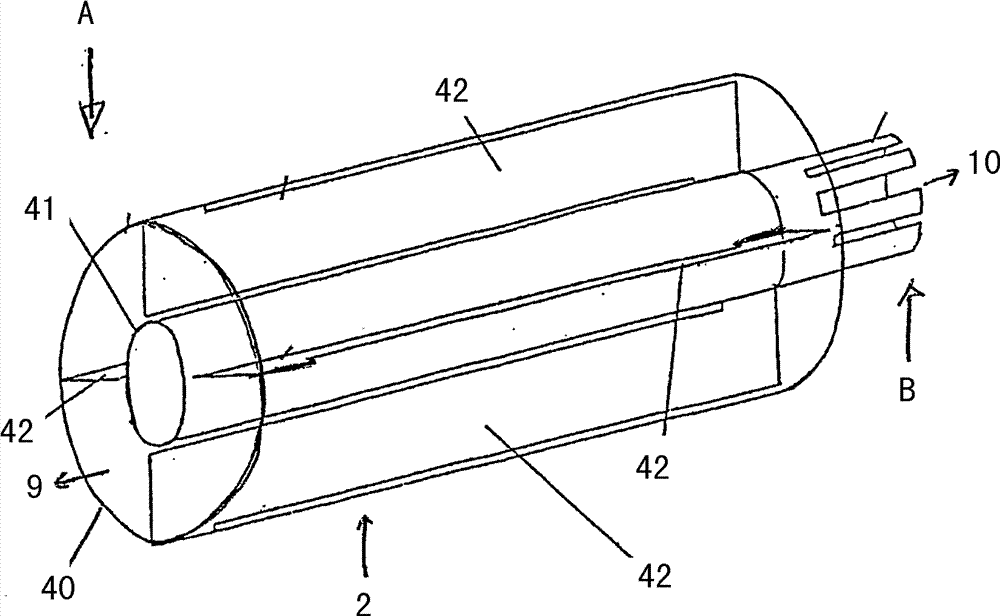

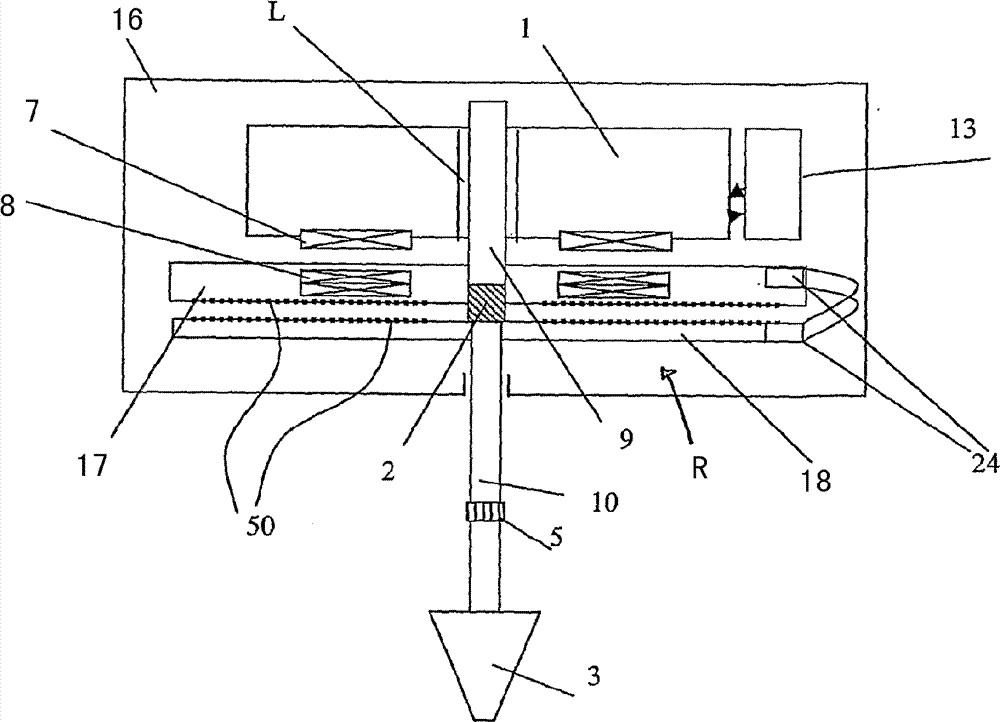

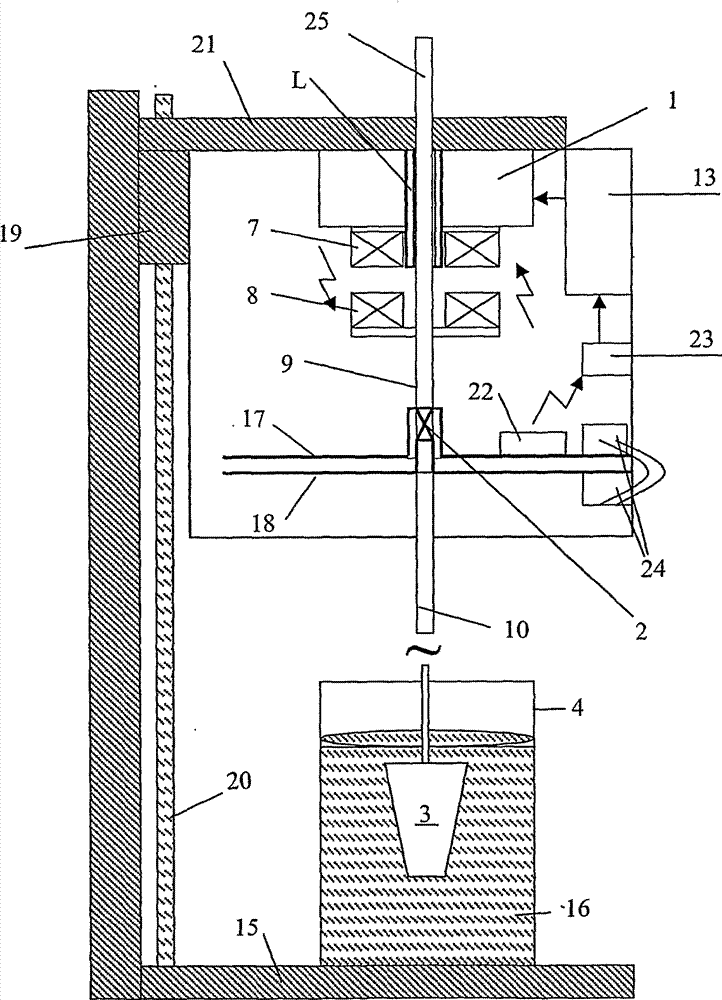

[0039] exist figure 1 The rotational viscometer shown schematically in has a unit with a drive motor 1 and a measuring shaft 25 driven by the drive motor 1 . In its region close to the electric motor, the measuring shaft 25 comprises a shaft part 9 connected to the electric motor, which carries the twistable element 2 . The element 2 carries the underlying shaft part 10 , which in turn carries the measuring part 3 . Measuring sensor parts 17 , 18 are arranged above and below the twistable element 2 . The upper measuring sensor part 17 carries a transmitter 22 with which measured values relating to the twisting of the twistable element 2 or the upper and lower measuring parts relative to one another are transmitted to an evaluation receiver. Unit 13. During the measurement, the electric motor 1 turns the measuring shaft 25 at a predetermined rotational speed. Due to the friction exerted by the sample on the measuring part 3 due to its viscosity, said measuring part 3 lags...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com