Rotational viscometer with paddle-type rotor and method for measuring particle fluid viscosity

A rotary viscosity and rotor technology, applied in the field of detection, can solve the problem of inability to accurately measure the viscosity of particle fluids, and achieve the effects of fast measurement speed, low cost and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Measuring the viscosity value of iron powder:

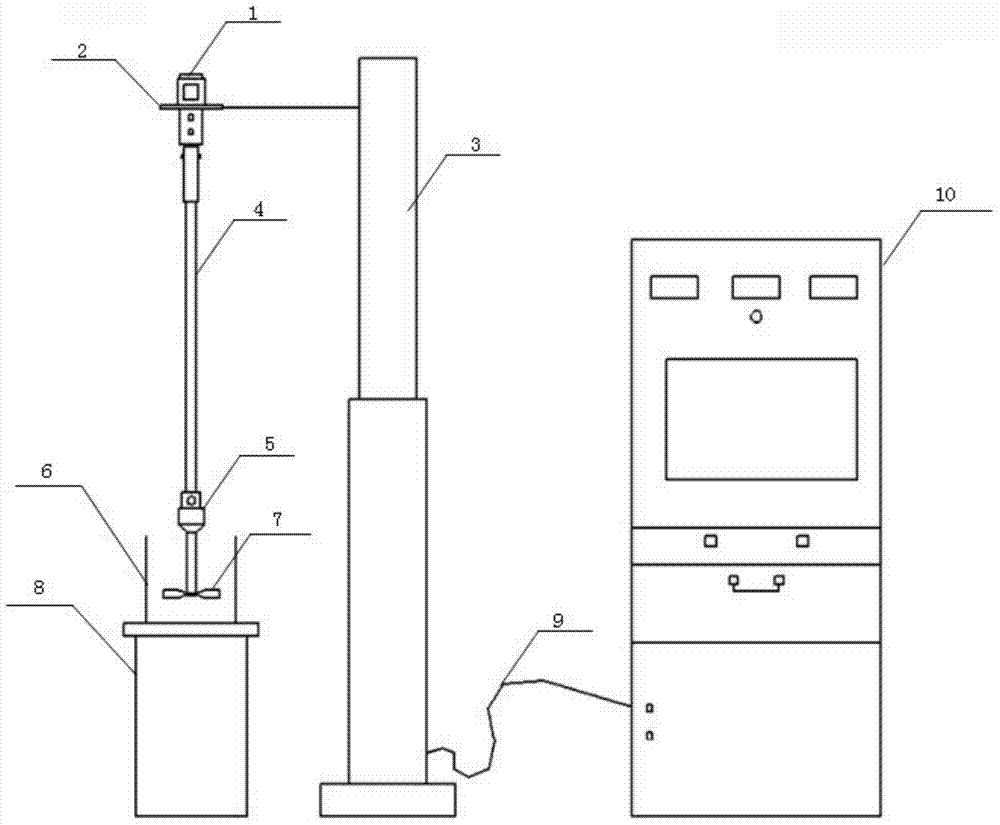

[0033] (1) Predict the viscosity of iron powder, select a torque sensor with a measuring range of 0-0.5N m, fasten the torque sensor on the bracket, and connect it to the control mechanism through a signal line;

[0034] (2) Connect the paddle-type rotor to the rotor, and the rotor is connected to the torque sensor through the rotor;

[0035] (3) Start the lifting mechanism, lower the paddle-shaped rotor into the sample chamber, and the end of the paddle-shaped rotor is 1mm away from the bottom of the sample chamber;

[0036] (4) Add the measured iron powder into the sample chamber, and the height of the iron powder in the sample chamber is 40mm;

[0037] (5) Turn on the torque sensor and set the speed to 180r / min. The torque sensor drives the paddle-type rotor to rotate in the iron powder through the rotating rod and the rotor head. The control mechanism shows that the measured torque is 0.085N·m. The calculation formul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com