Gel temporary plugging agent

A technology of temporary plugging agent and jelly, which is applied in the field of partially hydrolyzed polyacrylamide phenolic jelly temporary plugging agent, can solve the problems of high polymer cost, poor operability, toxicity of crosslinking agent, etc., and achieves low cost and easy acquisition. , The effect of improving the strength of jelly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

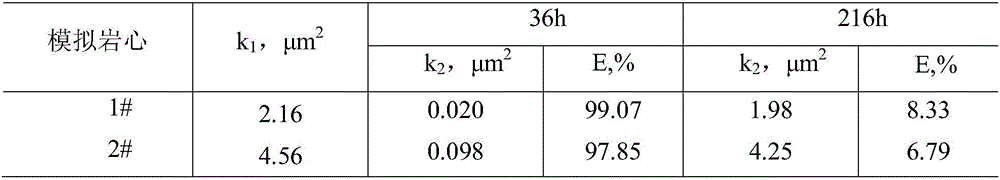

[0029] Add 0.05g resorcinol, 0.05g urotropine, 0.4g acetic acid to a beaker, add tap water to 50g, stir evenly to make it fully dissolved, add 0.3g partially hydrolyzed polyacrylamide and 0.05g Water-soluble polyvinyl alcohol, then add tap water until 50g is fully dissolved, then mix the solutions in the above two beakers, stir evenly, and obtain the jelly temporary blocking agent gel of the present invention. Take 20ml and put it into an ampoule bottle, sinter and seal it, and place it in a constant temperature water bath at 45°C to observe that the gelation time is 36 hours, the gelation time is 216h, and the viscosity after gelation is 7.8mPa·s.

[0030] Inspection of blocking ability:

[0031] Investigate the plugging ability of the jelly provided by the present invention. The specific experimental process is as follows: two sand-filling tubes with an inner diameter of 2.5 cm and a length of 20 cm are filled with quartz sand to obtain high and low permeability simulated c...

Embodiment 2

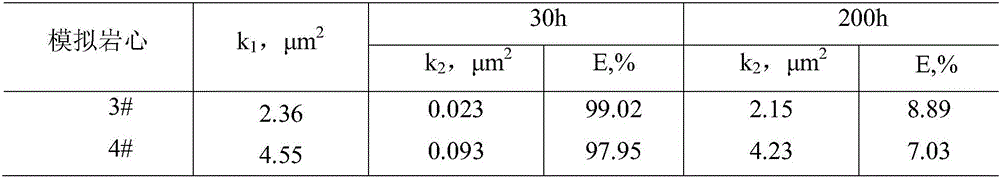

[0035] Add 0.06g resorcinol, 0.06g urotropine, 0.4g acetic acid in a beaker, add 5% NaCl aqueous solution to 50g and stir evenly to make it fully dissolved, add 0.3g partially hydrolyzed polyacrylamide and 0.1g water-soluble polyvinyl alcohol, add 5%NaCl aqueous solution again to 50g and fully dissolve, then mix the solutions in the above-mentioned two beakers, stir evenly, promptly obtain the jelly temporary plugging agent of the present invention into gelling solution. Take 20ml and put it into an ampoule bottle, sinter and seal it, and place it in a constant temperature water bath at 45°C to observe that the gelation time is 30 hours, the gelation time is 200h, and the viscosity after gelation is 7.3mPa·s.

[0036] Investigate the plugging ability of the jelly provided by the present invention. The specific experimental process is as follows: two sand-filling tubes with an inner diameter of 2.5 cm and a length of 20 cm are filled with quartz sand to obtain high and low perm...

Embodiment 3

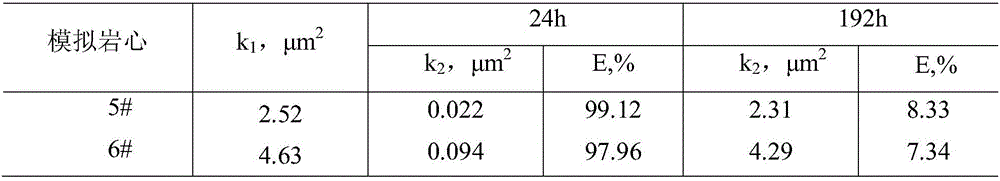

[0040] Add 0.06g resorcinol, 0.06g urotropine, 0.3g acetic acid, 0.2g sodium fluoroborate to a beaker, add tap water to 50g, stir well to make it fully dissolved, add 0.35g to another beaker to partially hydrolyze Polyacrylamide and 0.1g water-soluble polyvinyl alcohol are added with tap water until 50g is fully dissolved, then the solutions in the above two beakers are mixed and stirred evenly to obtain the jelly temporary plugging agent gelling solution of the present invention. Take 20ml and put it into an ampoule bottle, sinter and seal it, and place it in a constant temperature water bath at 65°C to observe that the gelation time is 24 hours, the gelation time is 192h, and the viscosity after the gelation is 6.5mPa·s.

[0041] Inspection of blocking ability:

[0042] Investigate the plugging ability of the jelly provided by the present invention. The specific experimental process is as follows: two sand-filling tubes with an inner diameter of 2.5 cm and a length of 20 cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com