Fracturing composite thickener

A thickening agent and fracturing technology, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of large amount of thickening agent, low-cost development of oilfields and increased material costs, etc., to achieve stable output and price, reduce This and inhibition effect are obvious and the effect of good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

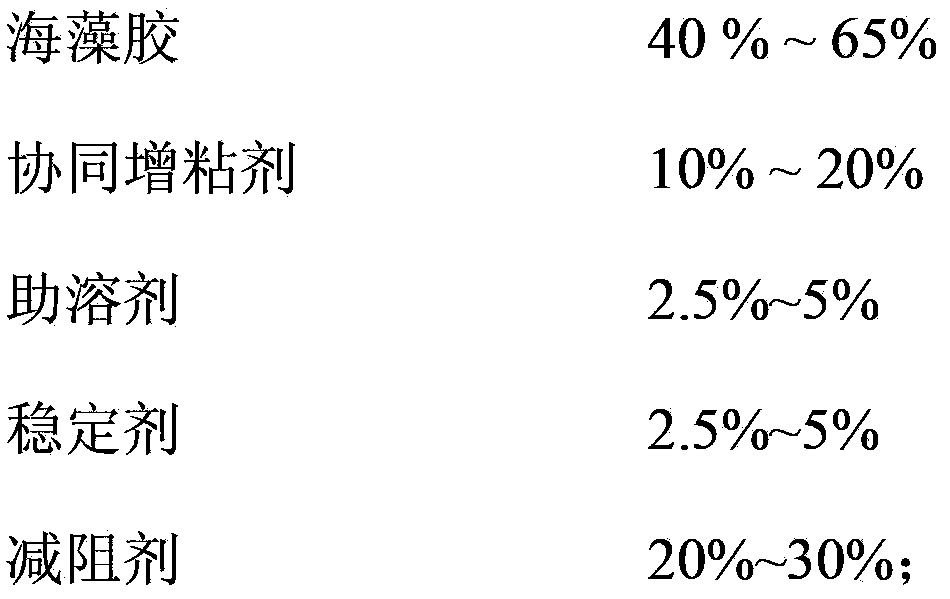

[0016] Mix 1# thickener with the following composition and ratio:

[0017]

[0018] Use a mixer to prepare the above-mentioned thickener solution according to 0.15%, and use a six-speed rotary viscometer to measure the viscosity. The indicators are as follows:

[0019] Complete swelling time: 15 minutes;

[0020] Apparent viscosity (normal temperature, 170S -1 ): 9mPa.s;

[0021] Proppant (20 / 40 mesh ceramsite, particle density: 3.1g / cm 3 ) Static sedimentation rate: 3.3cm / s.

[0022] Use a mixer to prepare the above thickener solution according to 0.5%, and use a six-speed rotary viscometer to measure the viscosity. The indicators are as follows:

[0023] Complete swelling time: 35 minutes;

[0024] Apparent viscosity (normal temperature, 170S -1 ): 54mPa.s;

[0025] Proppant (20 / 40 mesh ceramsite, particle density: 3.1g / cm 3 ) Static sedimentation rate: 0.9cm / s. Example 2

Embodiment 2

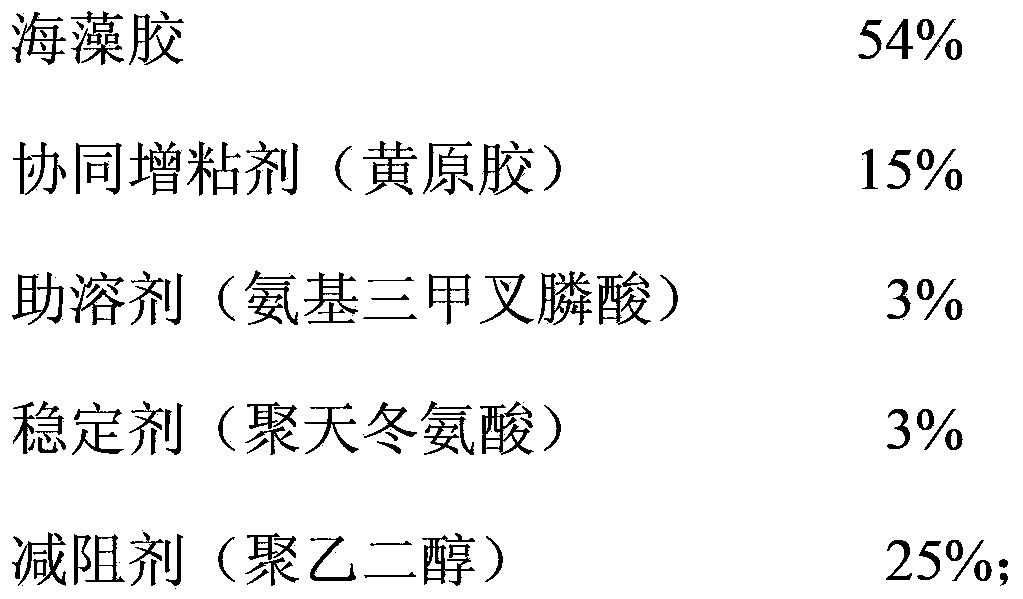

[0026] Mix 1# thickener with the following composition and ratio:

[0027]

[0028] Use a mixer to prepare the above-mentioned thickener solution according to 0.15%, and use a six-speed rotary viscometer to measure the viscosity. The indicators are as follows:

[0029] Complete swelling time: 12 minutes;

[0030] Apparent viscosity (normal temperature, 170S -1 ): 7.5mPa.s;

[0031] Proppant (20 / 40 mesh ceramsite, particle density: 3.1g / cm 3 ) Static sedimentation rate: 3.5cm / s.

[0032] Use a mixer to prepare the above thickener solution according to 0.5%, and use a six-speed rotary viscometer to measure the viscosity. The indicators are as follows:

[0033] Complete swelling time: 30 minutes;

[0034] Apparent viscosity (normal temperature, 170S -1 ): 42mPa.s;

[0035] Proppant (20 / 40 mesh ceramsite, particle density: 3.1g / cm 3 ) Static sedimentation rate: 1.1cm / s. Example 3

Embodiment 3

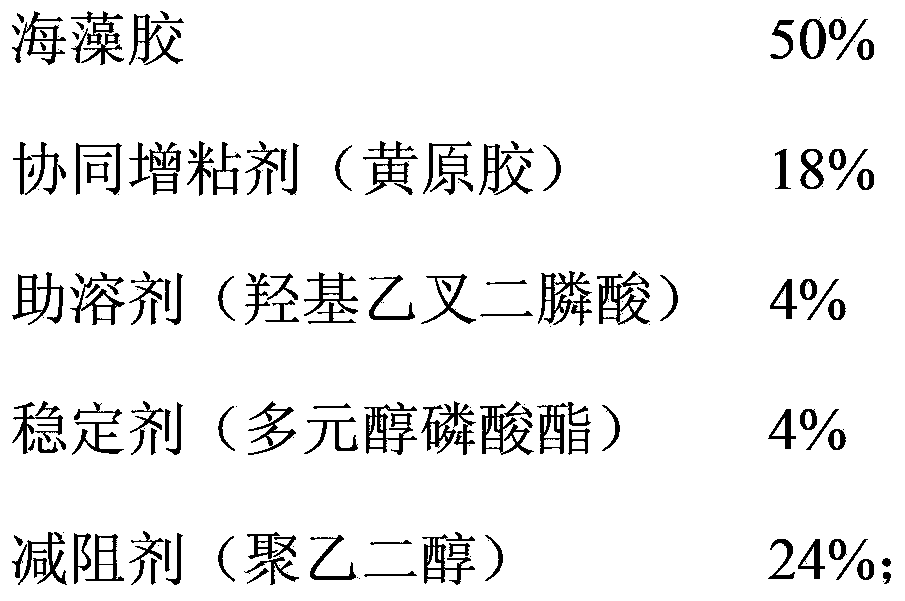

[0036] Mix 1# thickener with the following composition and ratio:

[0037]

[0038]

[0039] Use a mixer to prepare the above-mentioned thickener solution according to 0.15%, and use a six-speed rotary viscometer to measure the viscosity. The indicators are as follows:

[0040] Full swelling time: 20 minutes;

[0041] Apparent viscosity (normal temperature, 170S -1 ): 10.5mPa.s;

[0042] Proppant (20 / 40 mesh ceramsite, particle density: 3.1g / cm 3 ) Static sedimentation rate: 2.9cm / s.

[0043] Use a mixer to prepare the above thickener solution according to 0.5%, and use a six-speed rotary viscometer to measure the viscosity. The indicators are as follows:

[0044] Complete swelling time: 40 minutes;

[0045] Apparent viscosity (normal temperature, 170S -1 ): 52.5mPa.s;

[0046] Proppant (20 / 40 mesh ceramsite, particle density: 3.1g / cm 3 ) Static sedimentation rate: 0.7cm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| resistance reduction rate | aaaaa | aaaaa |

| resistance reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com