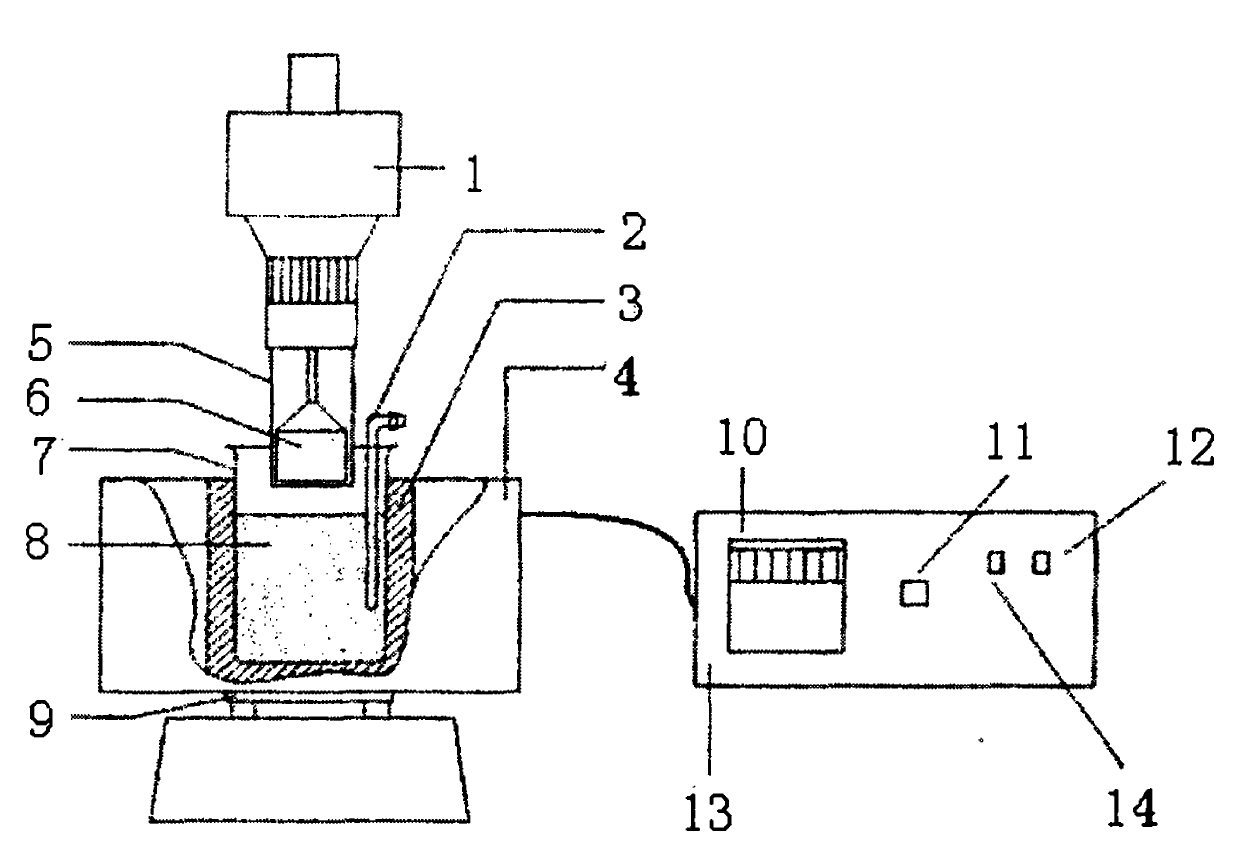

Rotational viscometer low temperature test device

A testing device, a technology of rotational viscosity, applied in measurement devices, flow characteristics, instruments, etc., can solve the problems of easy gelation, difficulty in well control, and increased liquid column pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Referring to the accompanying drawings, pour the sample to be tested into 7, put it into the device 3 together with 7, and then place it on the tray of 1. According to the required temperature, it is set by 10, after the temperature is set, press 12, press 14, the device enters the working state. After a few minutes, it can be detected by 11 that the temperature of the cooling body and the sample to be tested is constant enough. When the temperature is constant, rise 9 to make the inner page of the cup reach the 5 mark line for testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com