Offshore drilling controllable buoyant block

A technology for marine drilling and buoyancy blocks, applied in drilling equipment, drill pipes, drill pipes, etc., can solve the problems of vortex-induced vibration of buoyancy blocks, riser failure, riser wear, etc., to reduce current excitation and eddy current vibration, The effect of improving work efficiency and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

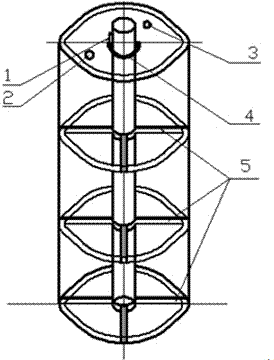

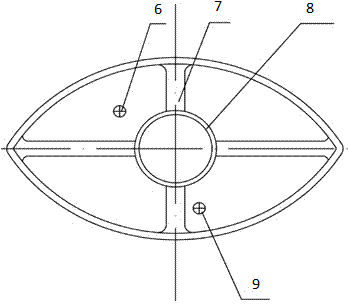

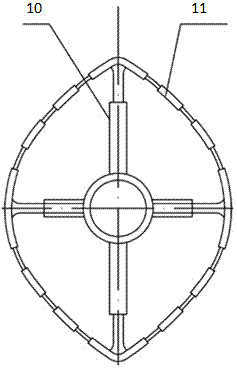

[0011] The details and work flow of the controllable buoyancy block for ocean drilling proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] In severe sea conditions, the control software controls the air compressor to inject air into the buoyancy block through the intake valve of the controllable buoyancy block of offshore drilling, and the outer material of the buoyancy block can expand after gas injection to provide variable buoyancy for the riser . After the sea state recovers, the control software sends instructions to the exhaust valve of the buoyancy block through the same path to discharge the rated gas volume, and the buoyancy block shrinks to return to the original equilibrium state. The buoyancy block has just played the effect of providing variable buoyancy like this. In addition, the guide ring on the top of the buoyancy block cooperates with the air injection of the compressor to automatically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com