A kind of zr-c-si polymer ceramic precursor and its preparation method and application

A ceramic precursor, zr-c-si technology, which is applied in the field of Zr-C-Si polymer ceramic precursor and its preparation and application, can solve the problems of harsh conditions, complicated preparation process and high reaction temperature, and achieve good resistance. High temperature performance, broad application prospects, and the effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Under nitrogen protection, add 0.55 g (0.002 mol) divinylzirconocene (A 2 monomer), 1.1g PCS (ie A 2 The mass ratio of monomer and PCS is 1:2 and 10 ml of toluene, the temperature is kept at 60-90 ° C, reacted for 48 hours under electromagnetic stirring, and the solution becomes viscous; add 90 ml of n-pentane, precipitate, filter, and put in a vacuum oven for 80 ℃ drying, to obtain Zr-C-Si ceramic precursor polymer (see figure 1 ). Yield 96%.

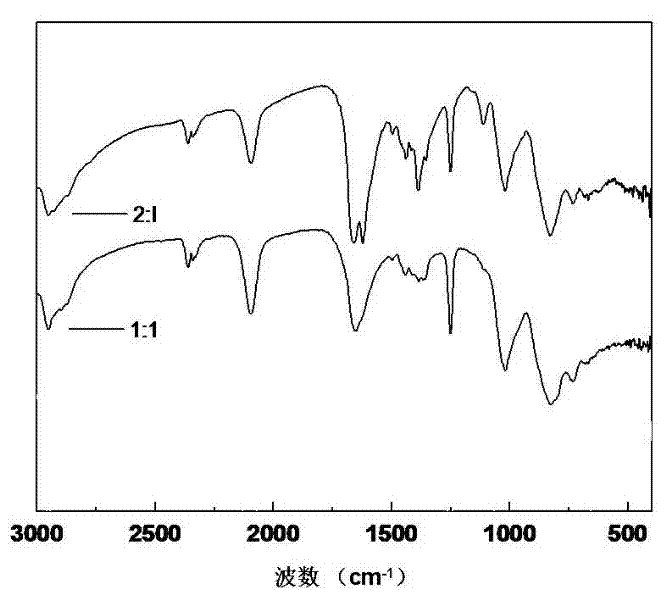

[0024] The obtained Zr-C-Si ceramic precursor polymer is soluble in DMF, NMP, DMAc and DMSO. In the IR spectrum, 2953 cm -1 and 2898 cm -1 are the carbon-hydrogen vibration absorption peaks on the methyl group and methylene group on the precursor polymer; 2099 cm -1 It is the characteristic absorption peak of the silicon-hydrogen bond on the main chain of the precursor polymer; 1650 cm -1 It is the characteristic absorption peak of carbon-carbon double bond; 1389 cm -1 and 1253 cm -1 It is the characteristic absorpt...

Embodiment 2

[0027] and The difference of embodiment 1 is only that raw material A 2 The mass ratio of monomer and PCS is 1:8. Under nitrogen protection, add 0.55 g (0.002 mol) divinylzirconocene (A 2 monomer), 4.4g PCS (ie A 2 The mass ratio of monomer and PCS is 1:8 and 18 ml of toluene, the temperature is kept at 70-80 ° C, reacted under electromagnetic stirring for 40 hours, the solution becomes viscous; add 180 ml of n-pentane, precipitate, filter, and put in a vacuum oven for 80 ℃ drying, the obtained Zr-C-Si ceramic precursor polymer is orange polymer powder. Yield 95%.

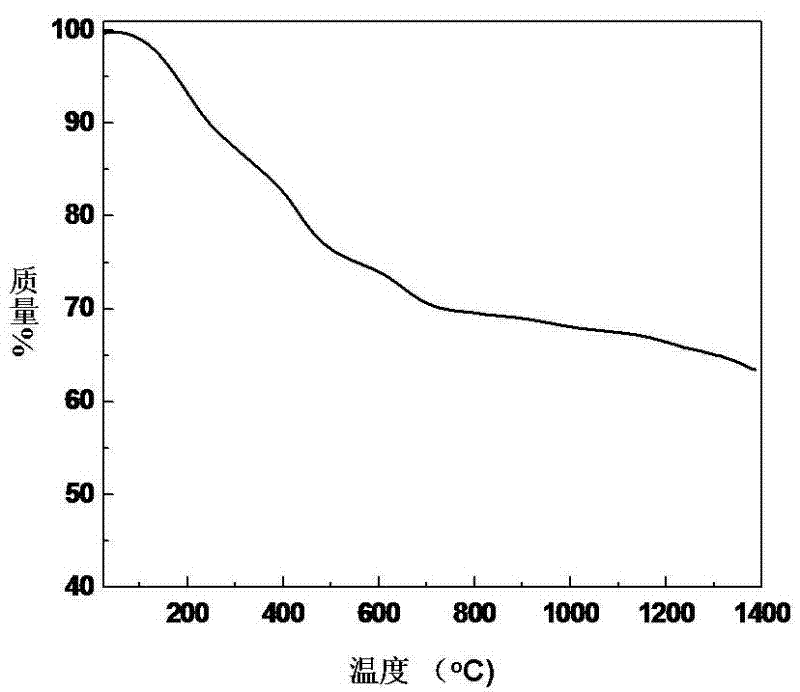

[0028] The obtained Zr-B-C ceramic precursor polymer is soluble in DMF, NMP, DMAc and DMSO. The Zr-C-Si ceramic precursor polymer is placed in nitrogen, cracked at a high temperature, the cracking temperature is controlled at 1700°C, and the cracking time is 1.5 hours to obtain Zr-C-Si ceramics. The ceramic yield is 54%. The ZrC / SiC content of the ultra-high temperature resistant component in the prepared Z...

Embodiment 3

[0030] The only difference with Example 1 is that raw material A 2 The monomer is changed from divinyl zirconocene to dipropenyl zirconocene, and the remainder is the same as in Example 1. Under the protection of nitrogen, add 0.606 g of dipropenylzirconocene (A 2 monomer), 0.606g PCS (ie A 2The mass ratio of monomer and PCS is 1:1 and 10 ml of toluene, the temperature is kept at 70-90 ° C, reacted for 45 hours under electromagnetic stirring, the solution becomes viscous; add 100 ml of n-pentane, precipitate, filter, and put in a vacuum oven for 80 ℃ drying, the obtained Zr-C-Si ceramic precursor polymer is orange-red polymer powder. Yield 92%. The obtained Zr-C-Si ceramic precursor polymer is soluble in DMF, NMP, DMAc and DMSO. The Zr-C-Si ceramic precursor polymer is placed in nitrogen, cracked at a high temperature, the cracking temperature is controlled at 1300° C., and the cracking time is 2 hours to obtain Zr-C-Si ceramics. The ceramic yield is 45%. The ZrC / SiC con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com