Preparation method and application of carbide ceramic precursor

A ceramic precursor and carbide technology, which is applied in the field of ultra-high temperature ceramics, can solve the problems of humidity sensitivity, low product purity, and high preparation temperature, and achieve the effect of easy composition, high purity, and low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

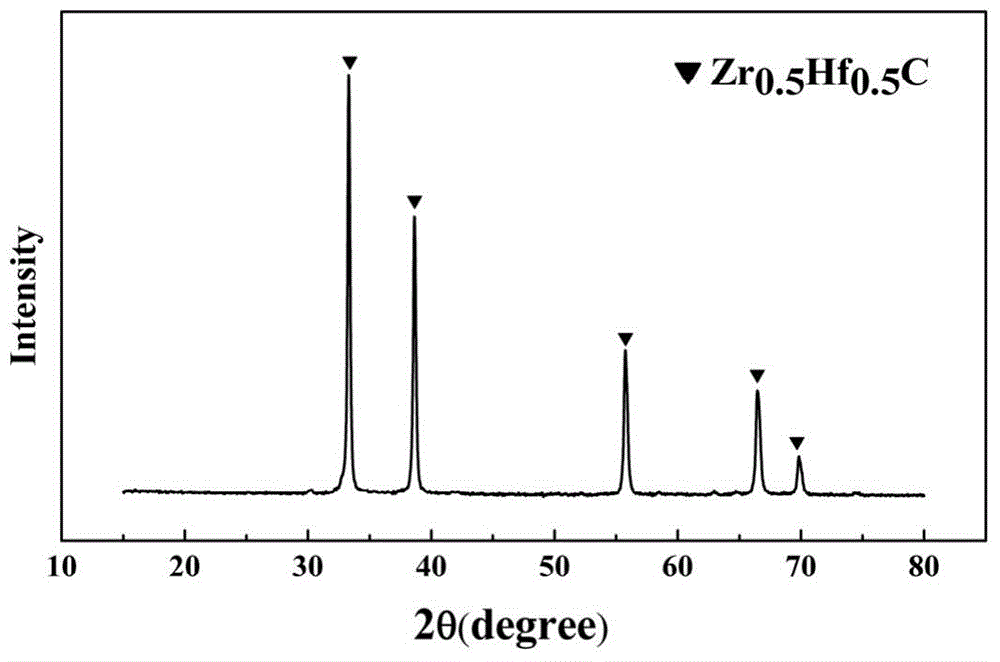

[0039] a) ZrCl with a molar ratio of 0.5:0.5:5:0:50 4 , HfCl 4 , Tartaric acid, ethylene glycol and distilled water are added to a beaker, placed on a magnetic stirrer, heated to about 60 ℃ and stirred until the reactants are dissolved, to obtain zirconium, hafnium ternary carbide solid solution ceramic precursor;

[0040] b) Heating the zirconium and hafnium ternary carbide solid solution ceramic precursors at 60°C for 40 hours to obtain the crosslinked product;

[0041] c) Put the cross-linked product in an alumina crucible, put it into a high-temperature cracking furnace, heat it up to 1300°C at 7°C / min in an argon atmosphere, keep it for 5 hours, and take out the zirconium and hafnium ternary carbide solid solution ceramics.

Embodiment 2

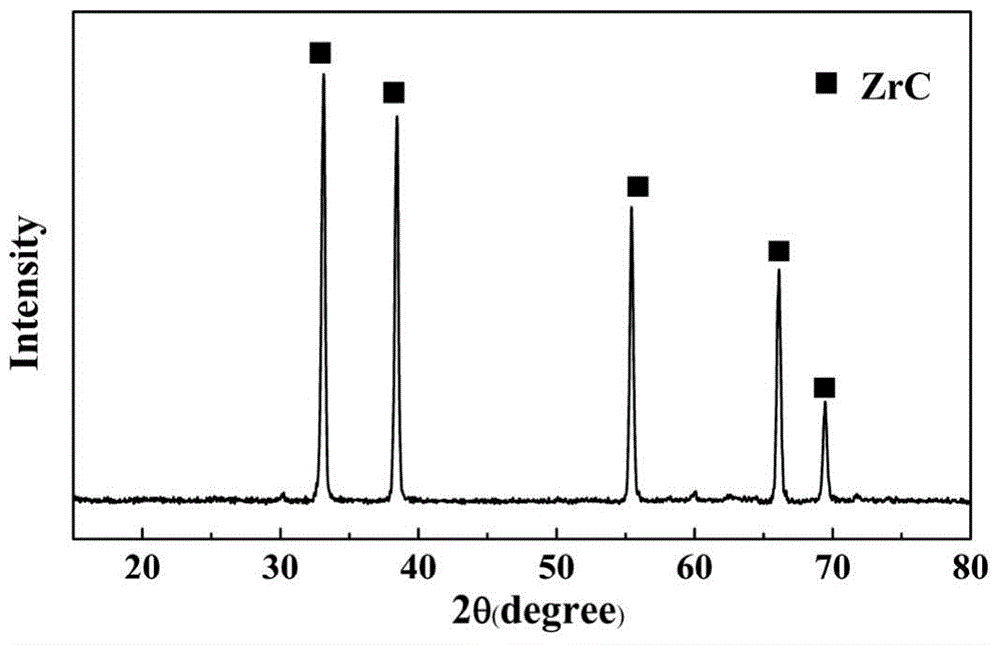

[0043] a) ZrOCl with a molar ratio of 1:0:8:500 2 ·8H 2 O, tartaric acid, glycerol and solvent distilled water are added to the beaker, placed on a magnetic stirrer and stirred to dissolve, after the dissolution is completed, the ZrC ceramic precursor is obtained;

[0044] b) Heating the ZrC ceramic precursor at 200°C for 5 hours to obtain a cross-linked product;

[0045] c) Put the cross-linked product in an alumina crucible, put it into a high-temperature cracking furnace, heat it up to 1600°C at 6°C / min in an argon atmosphere, hold it for 0.5h, and take out the ZrC ceramic.

Embodiment 3

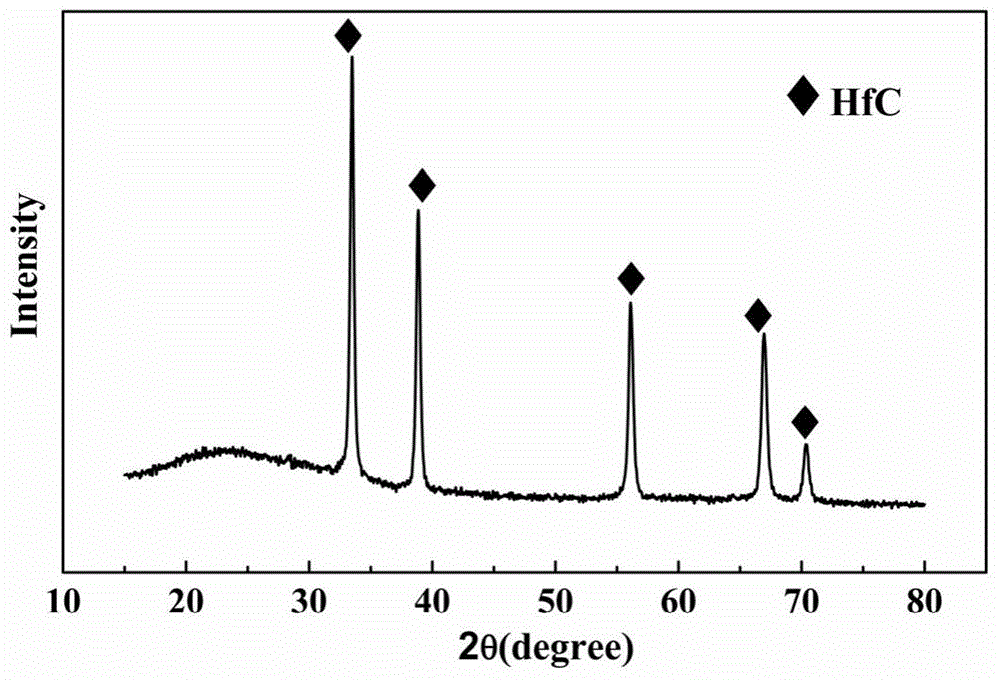

[0047] a) HfCl with a molar ratio of 1:1:1:200 4 , Malic acid, glycerol and solvent distilled water are added to a beaker, placed on a magnetic stirrer and stirred to dissolve, after the dissolution is completed, the HfC ceramic precursor is obtained;

[0048] b) Heating the HfC ceramic precursor at 100°C for 10 hours to obtain a crosslinked product;

[0049] c) Put the cross-linked product in an alumina crucible, put it into a high-temperature cracking furnace, heat it up to 1400°C at 6°C / min in an argon atmosphere, vacuum and keep it for 2h, and take out the HfC ceramic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com