Preparation method of ultrahigh-temperature ceramic modified C/C composite material

A technology of ultra-high temperature ceramics and composite materials, which is applied in the field of preparation of ultra-high temperature ceramic modified C/C composite materials, can solve the problems of high infiltration temperature, decreased mechanical properties of materials, and reduced alloy Si ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

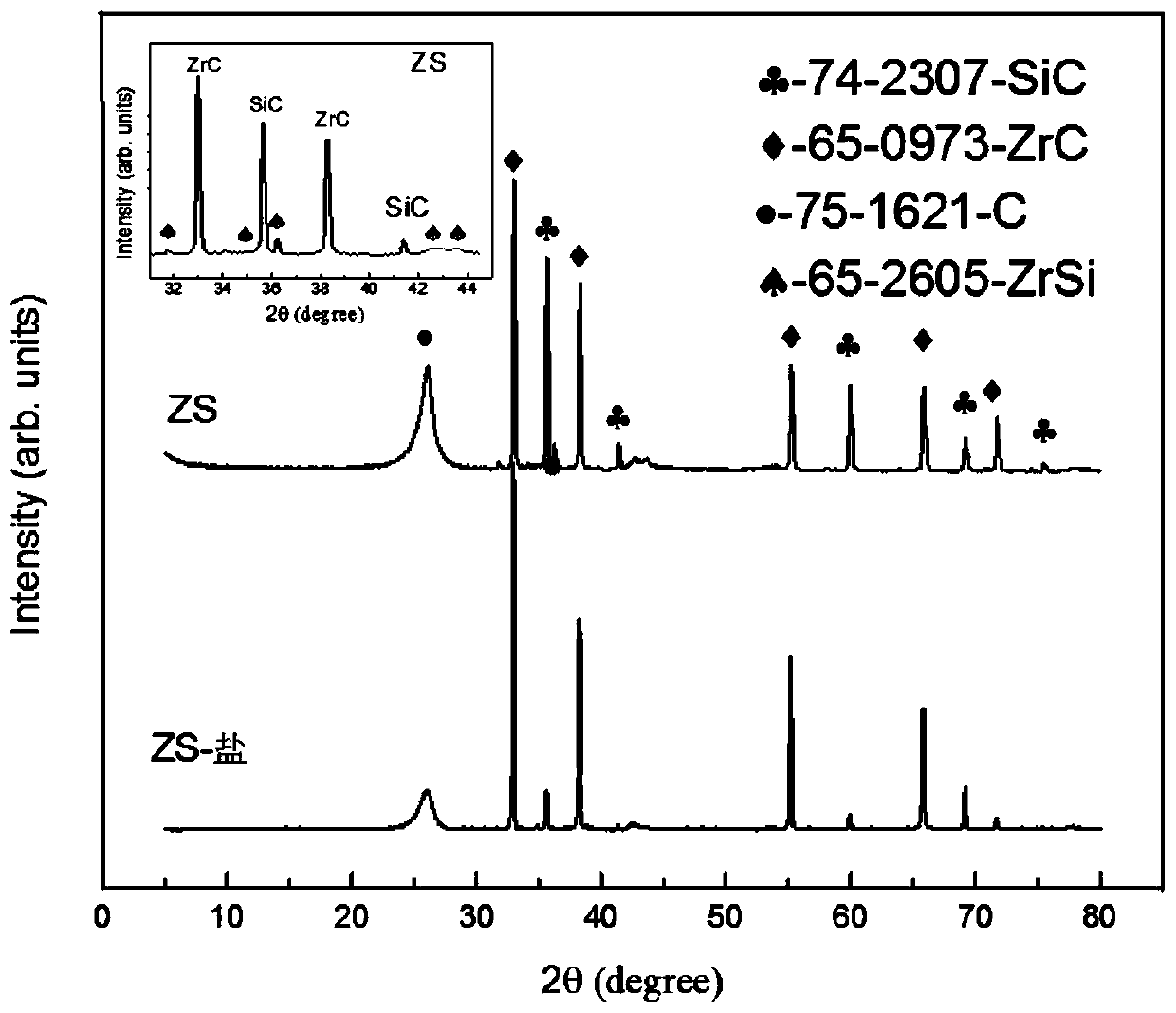

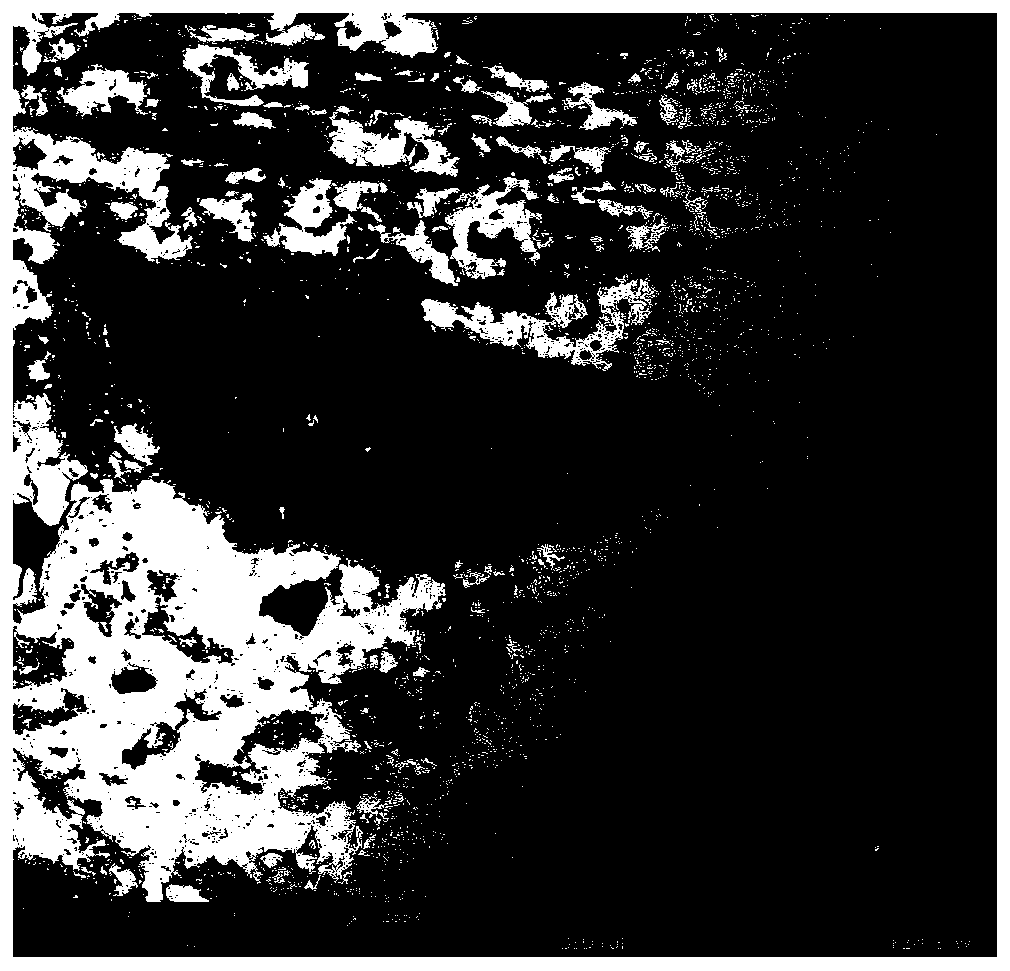

Embodiment 1

[0047] First, polish the 2.5D needle-punched C / C composite material with SiC sandpaper. The matrix density of the C / C composite material is 1.25g / cm. 3 ; The Zr and Si elemental powders are mixed uniformly according to the mass ratio of 6:4, and mixed with alcohol for 12h, dried in a blast box and sieved to obtain a uniformly mixed Zr-Si powder.

[0048] Mix Zr-Si powder, K 2 ZrF 6 , NaCl salt is dry mixed, the mixing ratio is 8:8:1, and the infiltration powder is obtained after mixing for 12 hours.

[0049] Put the C / C composite material matrix into the bottom of the graphite crucible, embed the infiltrating powder into the matrix, and finally put the crucible into a medium and high frequency graphitization furnace for infiltration under an argon atmosphere. Infiltration process: heat up from room temperature to 1200°C and keep it for 1h, then pump to minus 200Pa, then immediately inflate and continue to heat up at 1900°C and keep it for 2h. The heating rate in the whole process is...

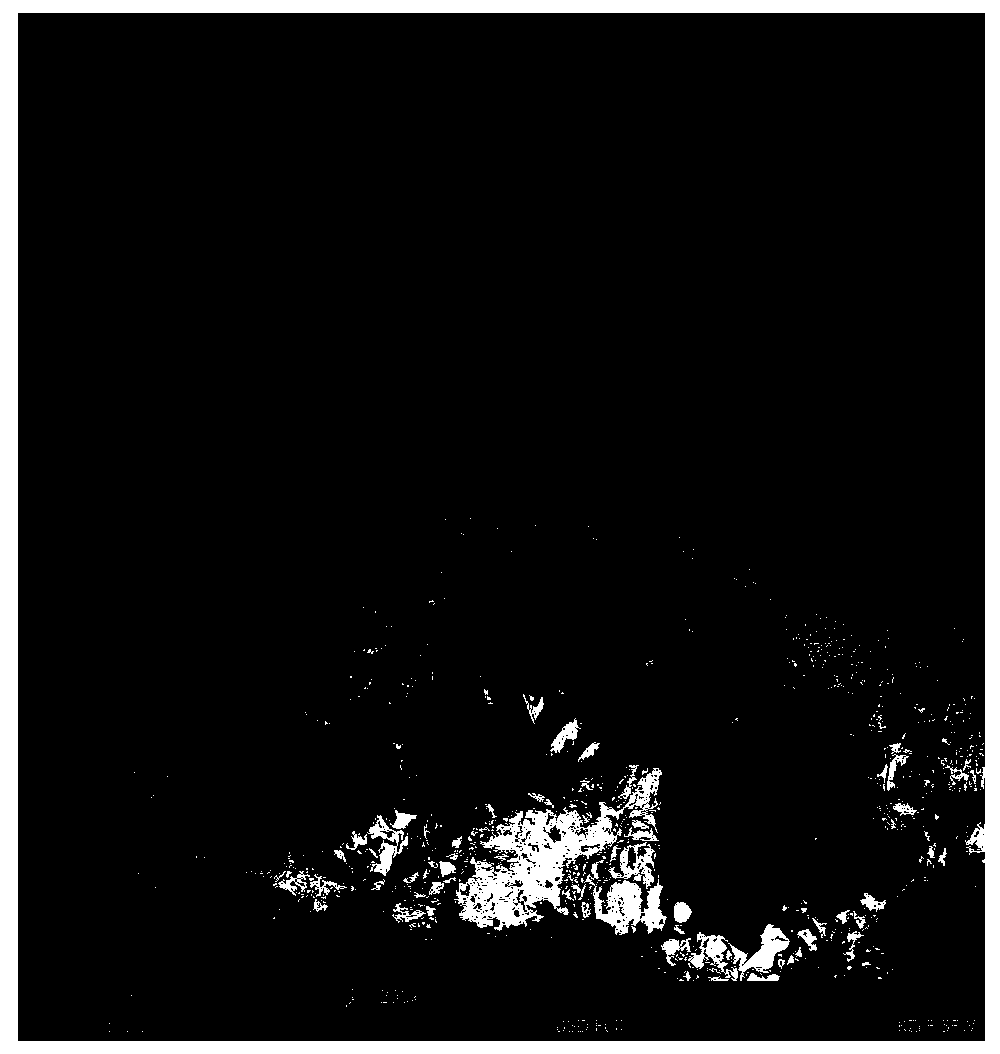

Embodiment 2

[0053] First, polish the 2.5D needle-punched C / C composite material with SiC sandpaper. The matrix density of the C / C composite material is 1.25g / cm. 3 ; The Zr and Si elemental powders are mixed uniformly according to the mass ratio of 6:4, and mixed with alcohol for 12h, dried in a blast box and sieved to obtain a uniformly mixed Zr-Si powder.

[0054] Mix Zr-Si powder, K 2 ZrF 6 , NaCl salt is dry mixed, the mixing ratio is 8:6:1, and the infiltration powder is obtained after mixing for 12 hours.

[0055] Put the C / C composite material matrix into the bottom of the graphite crucible, embed the infiltrating powder into the matrix, and finally put the crucible into the medium and high frequency graphitization furnace for infiltration under an argon protective atmosphere. Infiltration process: heating from room temperature to 1200℃ and holding for 1h, then pumping to minus 200Pa, then inflating and continuing to heat up at 1800℃ and holding for 2h, the whole heating rate is about 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com