Carbon removing apparatus and method for silicon carbide micropowder

A silicon carbide micropowder and roller technology, which is applied in the field of silicon carbide micropowder carbon removal devices, can solve the problems of high SiC content, high production cost, waste of resources, etc., and achieve the effects of reducing SiC content, low cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

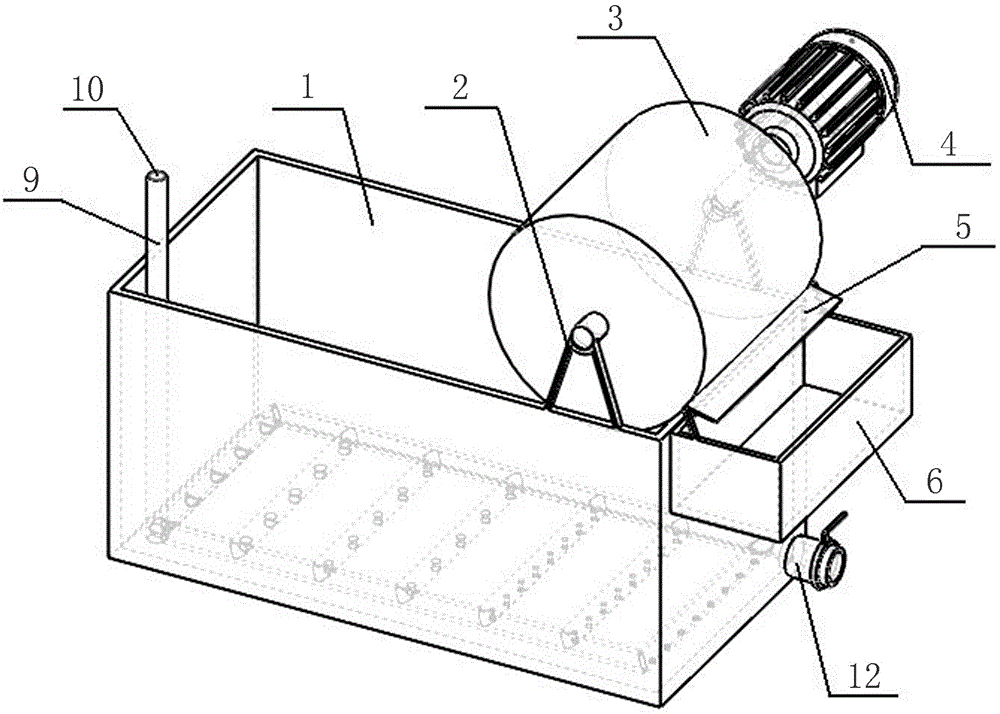

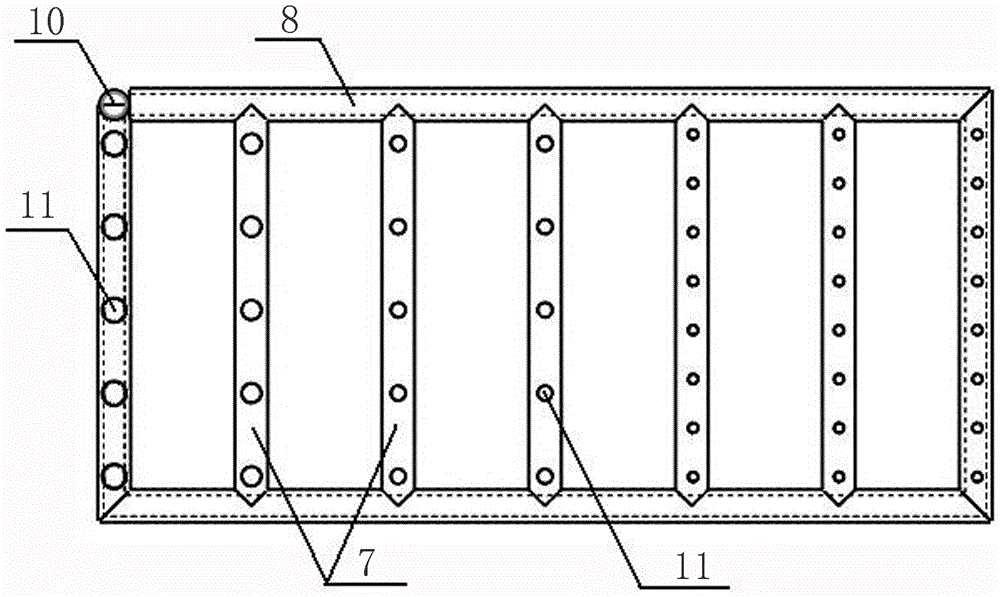

[0027] Embodiment 1: A kind of silicon carbide micropowder carbon removal device, see figure 1 , figure 2 , including a carbon removal pool 1, air blowing equipment, adsorption equipment and collection equipment, the adsorption equipment includes a roller support 2 arranged on the top of one side wall of the carbon removal pool 1, and a cylindrical roller 3 horizontally installed on the roller support 2 , and the drive mechanism 4 that is connected with the roller 3 and provides rotational power for the roller 3, the drive mechanism 4 is a drive motor; the bottom side of the roller 3 is located in the carbon removal pool 1, and the outer side is located in the carbon removal pool 1 outside the end side walls.

[0028] The collection equipment includes a scraper 5 and a carbon collection box 6 installed on the end side wall of the carbon removal tank 1, one side of the scraper 5 is tangent to the outer surface of the roller 3, and the other side extends to the upper opening o...

Embodiment 2

[0030] Embodiment 2: a kind of silicon carbide micropowder carbon removal method comprises the following steps:

[0031] (1) Slurry making: Add 0.5 tons of silicon carbide micropowder and deionized water to prepare a slurry with a solid content of 40%, then add 500mL of carbon collector, stir for 5 minutes, and pump the slurry into Example 1 for carbonization after the slurry is uniform In the carbon removal pool of silicon micropowder carbon removal device;

[0032] Among them: the carbon collector is kerosene. After testing, the content of free carbon in the silicon carbide powder is 0.46%, and the average particle size of the silicon carbide powder is 9.8 μm.

[0033] (2) Air blowing: Open the air intake valve and blow the slurry for 2 minutes, so that the carbon collector and carbon particles in the slurry are enriched on the surface of the slurry driven by the air bubbles.

[0034] (3) Adhesion carbon removal: start the adsorption equipment, the driving mechanism drives ...

Embodiment 3

[0037] Embodiment 3: a kind of silicon carbide micropowder carbon removal method comprises the following steps:

[0038] (1) Slurry making: Add 0.5 tons of silicon carbide micropowder and deionized water to prepare a slurry with a solid content of 40%, then add 1000mL of carbon collector, stir for 10 minutes, and pump the slurry into Example 1 for carbonization after the slurry is uniform In the carbon removal pool of silicon micropowder carbon removal device;

[0039] Among them: the carbon collector is terpineol. After testing, the content of free carbon in the silicon carbide powder is 0.53%, and the average particle size of the silicon carbide powder is 10.3 μm.

[0040] (2) Gas blowing: Open the air intake valve and blow the slurry for 5 minutes, so that the carbon collector and carbon particles in the slurry are enriched on the surface of the slurry driven by the air bubbles.

[0041] (3) Adhesion carbon removal: start the adsorption equipment, the driving mechanism dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com