Method for preparing continuous carbon fiber toughened ultrahigh-temperature ceramic-based composite material through electrophoretic deposition

An ultra-high temperature ceramic and electrophoretic deposition technology, which is applied in the field of ultra-high temperature ceramic matrix composite materials, can solve the problems of erosion, the difficulty of preparing ultra-high temperature ceramic matrix composite materials toughened by continuous carbon fibers, etc., so as to improve the high temperature resistance performance and avoid chemical reaction erosion. , optimize the effect of matrix components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

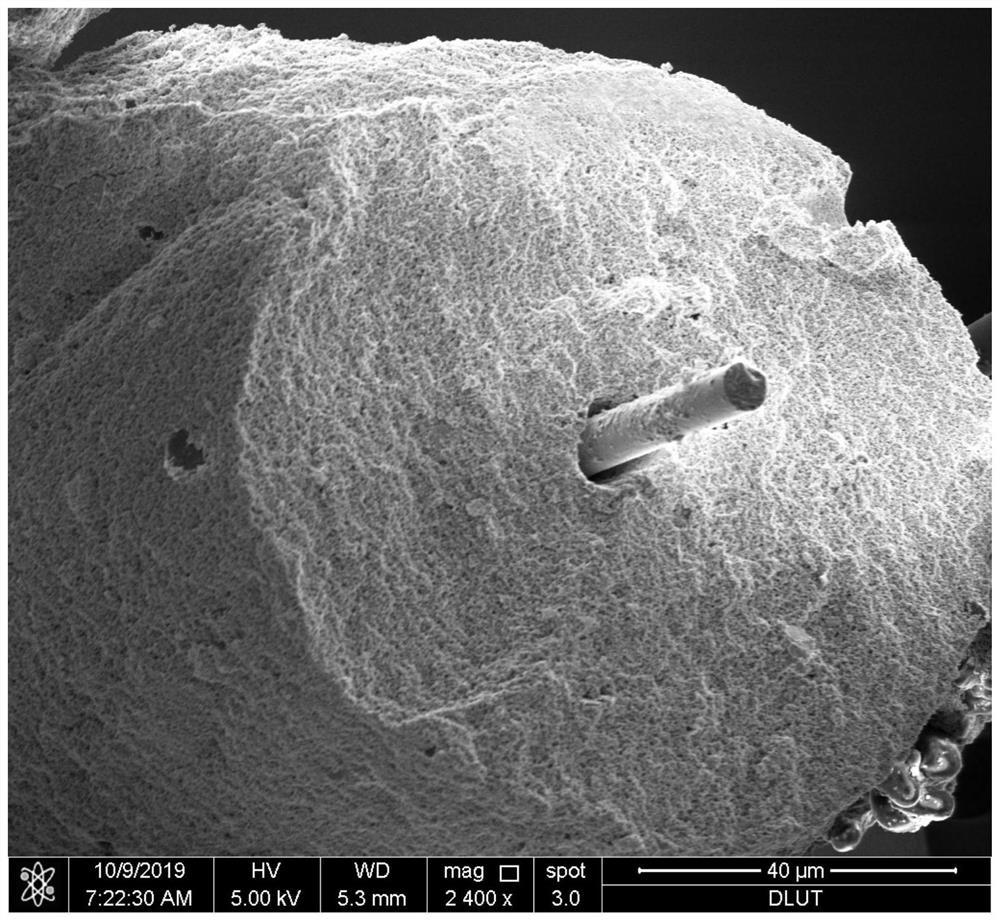

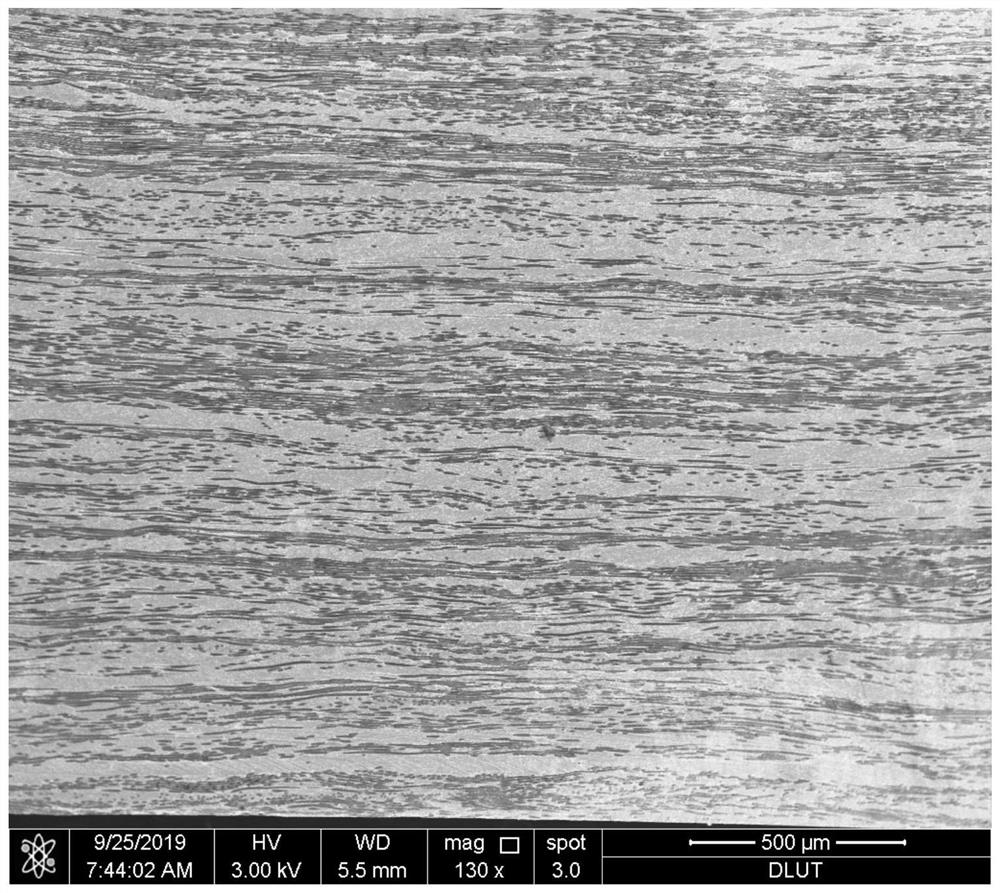

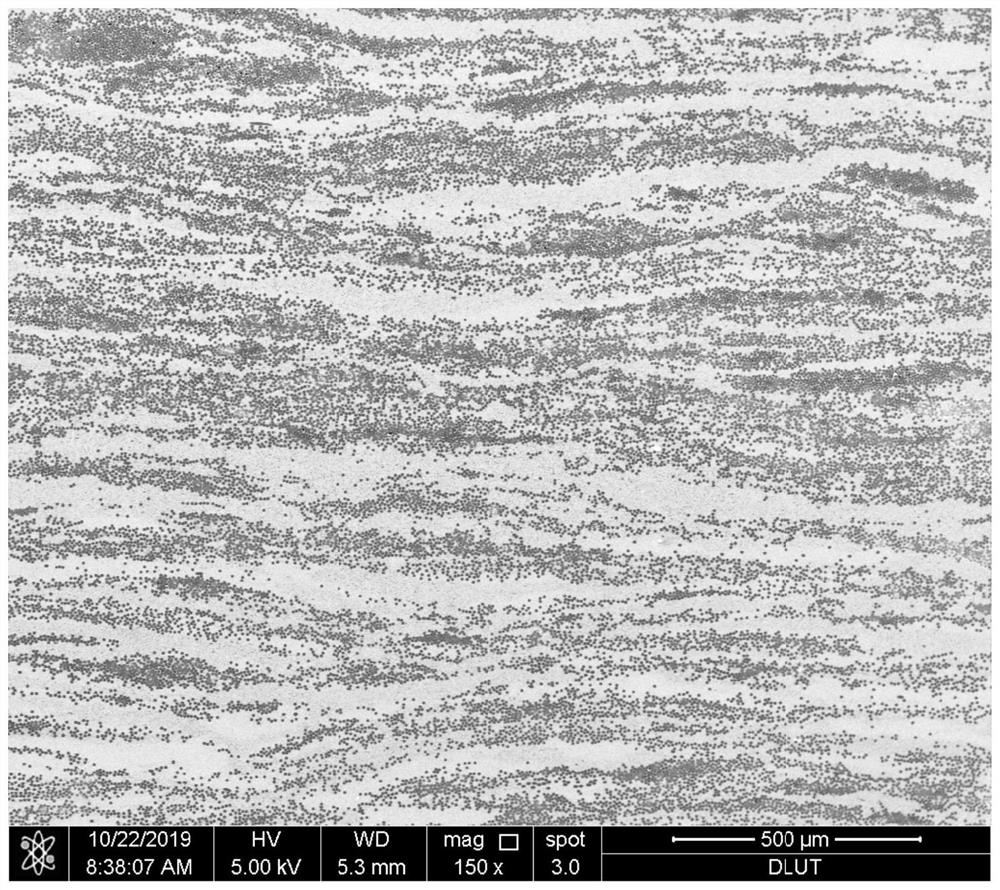

[0028] Continuous carbon fiber toughened ultra-high temperature ceramic matrix composites were prepared by electrophoretic deposition technology: firstly, polydopamine coating was prepared on carbon fibers by utilizing the oxidative self-polymerization of dopamine; secondly, polyethyleneimine was used to adsorb on the surface of ultra-high temperature ceramic powder and make super The high-temperature ceramic powder is charged; then the charged ultra-high-temperature ceramic powder is uniformly deposited on the carbon fiber containing polydopamine coating by electrophoretic deposition technology; finally, the continuous carbon fiber toughened ultra-high-temperature ceramic matrix composite material is obtained by high-temperature hot-pressing sintering; Specific steps include:

[0029] First, prepare polydo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com