Low-density carbon-tile surface oxidation-resistant coating capable of resisting temperature of 1700 DEG C and preparation method thereof

A technology of anti-oxidation coating and anti-oxidation layer, which is applied in the field of thermal protection materials, can solve the problems of limited temperature resistance level of anti-oxidation coating, oxidation ablation, etc., achieve short cycle, improve temperature resistance level, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing an anti-oxidation coating on the surface of a low-density carbon tile resistant to 1700°C, the specific steps are:

[0036] 1) According to the shape characteristics and dimensions of different heat protection products, low-density carbon tiles are processed to ensure the processing accuracy and obtain low-density carbon tile base materials;

[0037] 2) Use Si, B, C, O ceramic precursors to brush and impregnate the low-density carbon tile base material obtained in step 1) for 2 to 4 times, and dry once after each brushing. The drying temperature is 250~300℃, keep warm for 2~3 hours;

[0038] 3) Perform high-temperature pyrolysis on the intermediate state sample obtained in step 2). The pyrolysis treatment temperature is 1000-1300 ° C, and the temperature is kept for 1-3 hours. After each cracking, the surface of the sample is treated to remove the soft bonding powder produced by surface cracking. body particles;

[0039] 4) Repeat steps 2) to 3)...

Embodiment 1

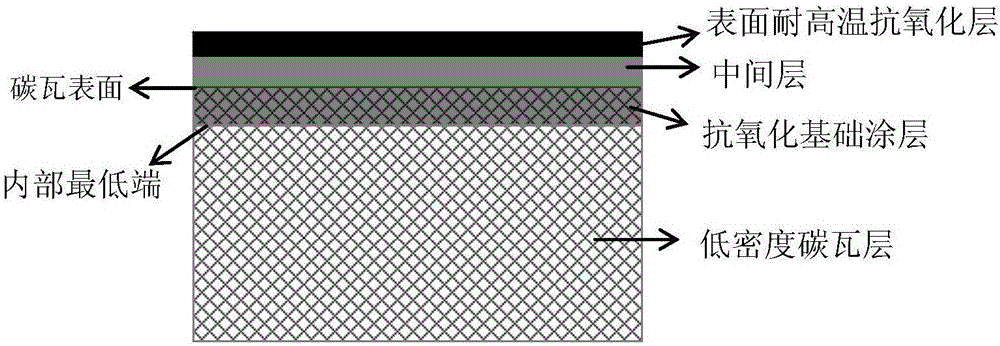

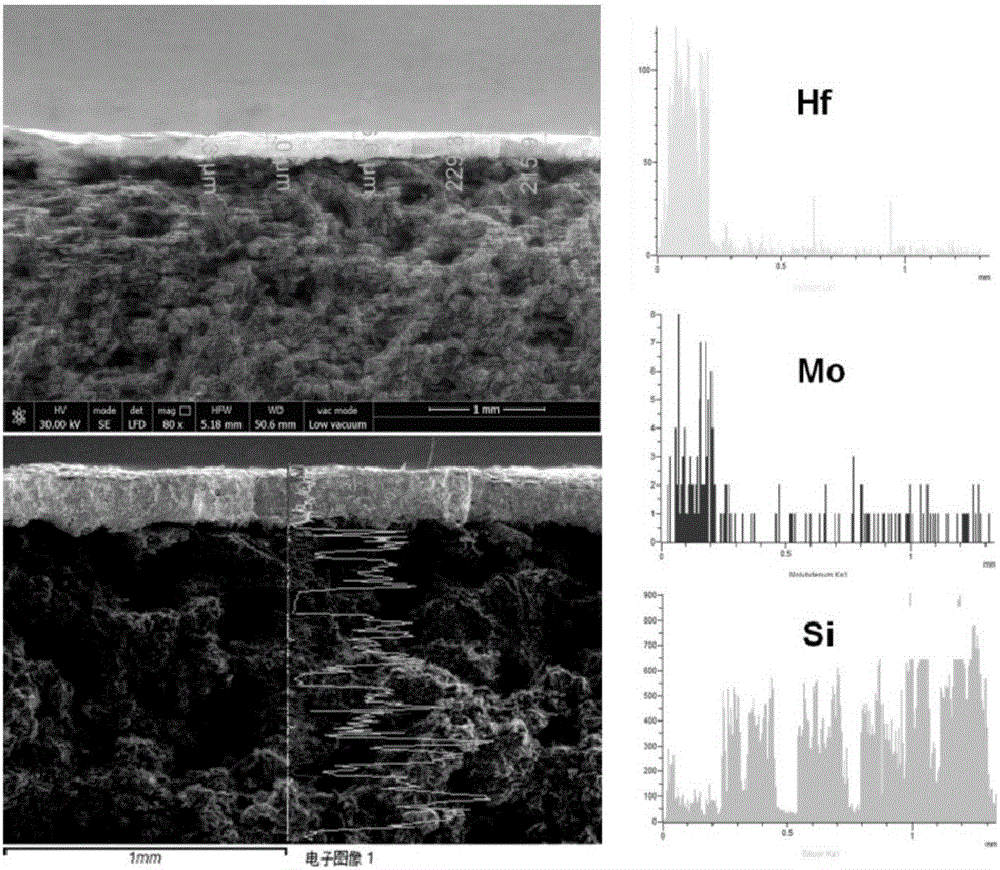

[0062] An anti-oxidation coating on the surface of low-density carbon tiles resistant to 1700°C, the anti-oxidation coating includes an anti-oxidation transition layer and a surface high temperature resistant anti-oxidation layer; the anti-oxidation transition layer includes an anti-oxidation base coating and an intermediate layer, such as figure 1 shown; wherein the anti-oxidation base coating is a refractory metal compound, and the refractory metal compound enters the position at the lowest end of the low-density carbon tile to the top of the low-density carbon tile, that is, the position on the surface of the low-density carbon tile, and its content increases successively ; The total thickness of the anti-oxidation base coating and the intermediate layer is 2.1-2.5 mm, and the elemental composition of the refractory metal compound includes Si and C; the elemental composition of the intermediate layer is Si and C, and the surface High temperature resistant and anti-oxidation ...

Embodiment 2

[0073] An anti-oxidation coating on the surface of low-density carbon tiles resistant to 1700°C, the anti-oxidation coating includes an anti-oxidation transition layer and a surface high temperature resistant anti-oxidation layer; the anti-oxidation transition layer includes an anti-oxidation base coating and an intermediate layer, such as figure 1 shown; wherein the anti-oxidation base coating is a refractory metal compound, and the refractory metal compound enters the position at the lowest end of the low-density carbon tile to the top of the low-density carbon tile, that is, the position on the surface of the low-density carbon tile, and its content increases successively The total thickness of the anti-oxidation base coating and the intermediate layer is 2.0-2.7mm, and the elemental composition of the refractory metal compound includes Si, B, and C; the elemental composition of the intermediate layer is Si, B, and C, The high temperature resistant and anti-oxidation layer o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com