High-entropy carbide ultrahigh-temperature ceramic with ultrahigh porosity and preparation method

A technology of ultra-high temperature ceramics and carbides, applied in ceramic products, applications, household appliances, etc., can solve the problems of high thermal conductivity and achieve the effects of uniform composition, convenient operation, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

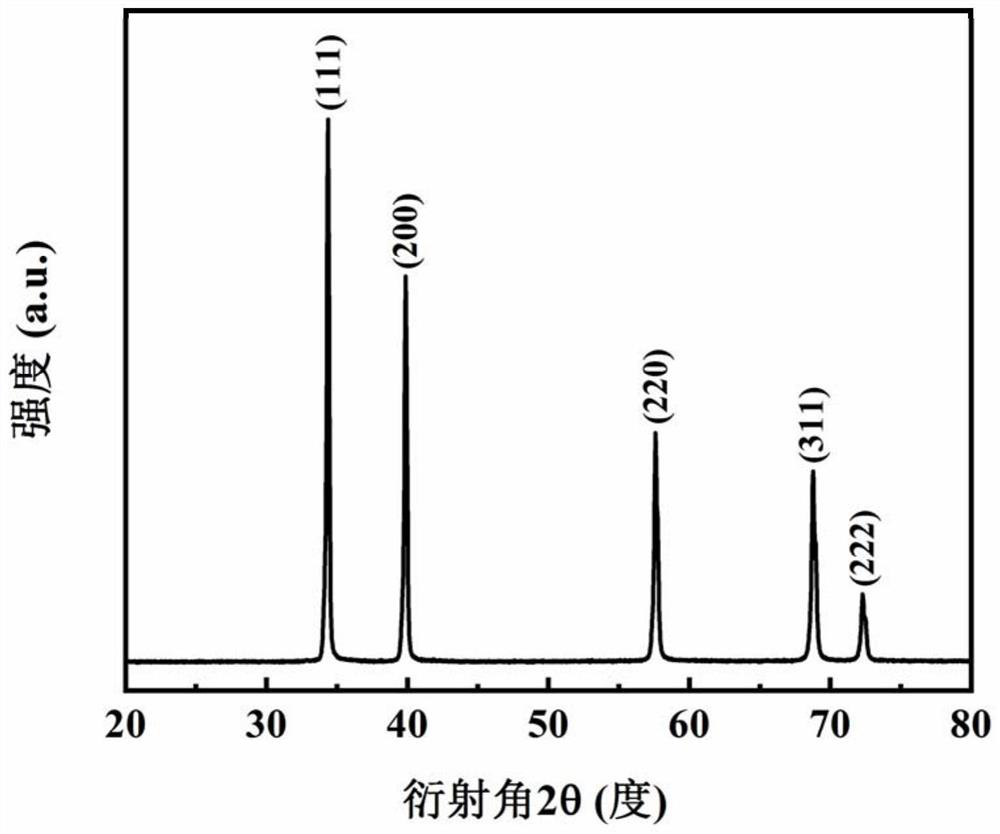

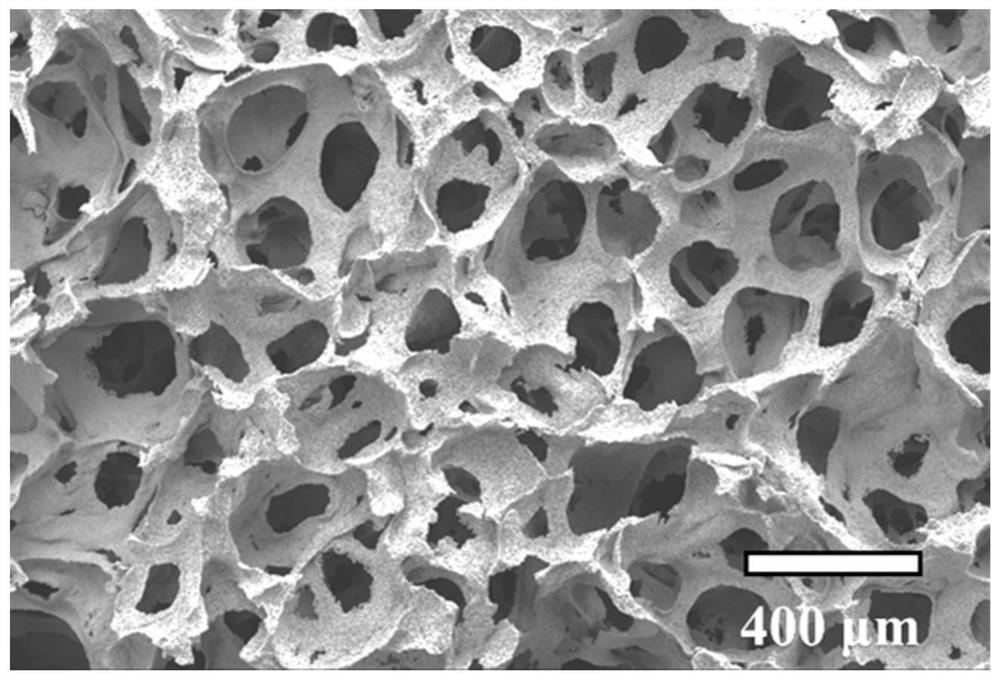

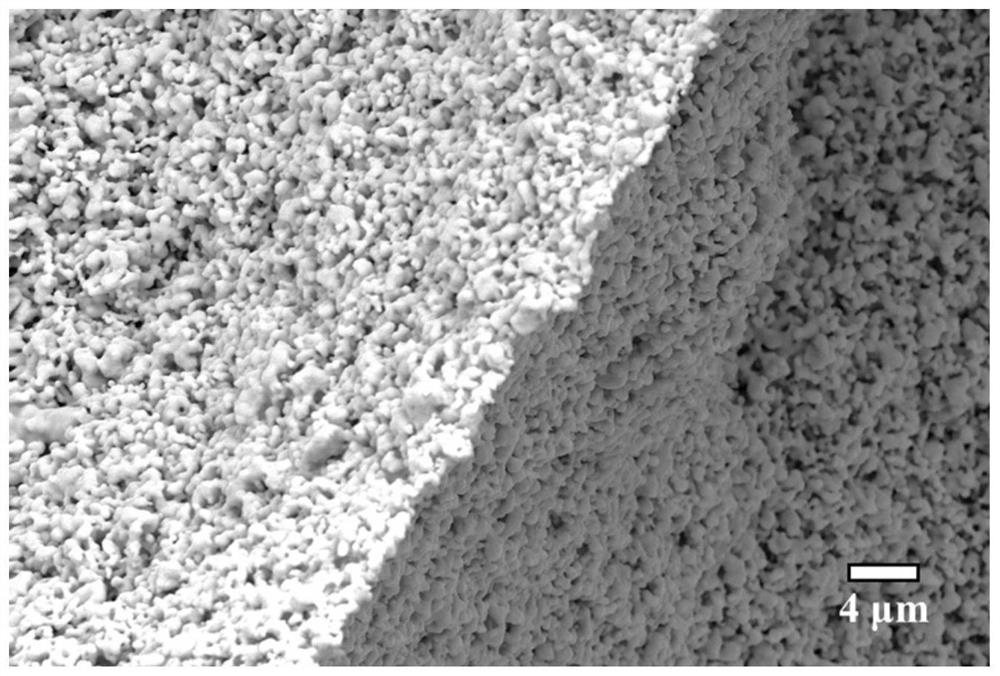

[0028] In this embodiment, the high-entropy carbide ultra-high temperature ceramic with ultra-high porosity and its preparation method are as follows:

[0029] Weigh 7.93g ZrC, 14.62g HfC, 8.05g NbC, 14.81g TaC and 4.60g TiC powder, pour into Si 3 N 4 In the ball mill tank, add 30ml of absolute ethanol and then carry out ball milling, in which the mass ratio of balls to materials is 4:1, use a planetary ball mill to mill at a speed of 350rpm for 12 hours, and dry the evenly mixed suspension in an oven at 90°C, and the dried powder Pass through a 200 mesh sieve to obtain a uniform mixture powder.

[0030] Add the mixture powder after ball milling, 30g deionized water, 0.5g dispersant ammonium citrate, and 1g sintering aid graphite into the beaker and stir continuously, and form a slurry after stirring for 2 hours; add 0.3g foaming Sodium dodecyl sulfonate, stirred rapidly for 15 minutes to foam, then added 1.8g of gelatin gelatin, stirred for 10 minutes, injected into the mol...

Embodiment 2

[0034] In this embodiment, the high-entropy carbide ultra-high temperature ceramic with ultra-high porosity and its preparation method are as follows:

[0035] Weigh 13.7g ZrC, 12.6g HfC, 20.9g NbC, 38.5g TaC and 4.2g VC powder, pour Si 3 N 4 In the ball milling tank, add 35ml of absolute ethanol and then carry out ball milling, in which the mass ratio of balls to materials is 3:1, use a planetary ball mill to mill at a speed of 260rpm for 28 hours, and dry the uniformly mixed suspension in an oven at 60°C, and the dried powder Pass through a 200 mesh sieve to obtain a uniform mixture powder.

[0036] Put the mixture powder after ball milling, 45g deionized water, 5.4g dispersant polyethyleneimine, 0.5g aluminum nitride into the beaker and keep stirring, and form a slurry after stirring for 1h; add 4.5g foam to the obtained slurry Foaming agent sodium lauryl sulfate, stirring rapidly for 25 minutes to foam, then adding 4.5g of gelatin gelatin, stirring for 20 minutes, inject...

Embodiment 3

[0040] In this embodiment, the high-entropy carbide ultra-high temperature ceramic with ultra-high porosity and its preparation method are as follows:

[0041] Weigh 4.1g ZrC, 15.1g HfC, 4.2g NbC, 23.0g TaC and 23.4g WC powder, pour into Si 3 N 4 In the ball milling tank, add 40ml of absolute ethanol and carry out ball milling, wherein the mass ratio of balls to materials is 6:1, use a planetary ball mill to mill at a speed of 310rpm for 20h, and dry the evenly mixed suspension in an oven at 75°C, and the dried powder Pass through a 200 mesh sieve to obtain a uniform mixture powder.

[0042] Add the mixture powder after ball milling, 30g of deionized water, 2.5g of dispersant polyethyleneimine, and 0.7g of silicon molybdenum to the beaker and stir continuously, and form a slurry after stirring for 4 hours; add 2.5g of foaming agent to the obtained slurry Sodium dodecyl sulfonate, stirred rapidly for 30 minutes to foam, then added 0.6g of gelatin gelatin, stirred for 15 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com