Clamping mechanism for device for testing high-temperature direct tensile strength of ultrahigh-temperature ceramics

A technology of ultra-high temperature ceramics and tensile strength, which is used in measuring devices, using stable tension/pressure to test the strength and strength characteristics of materials, etc. Achieve the effect of avoiding bending and twisting, accurate test results, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

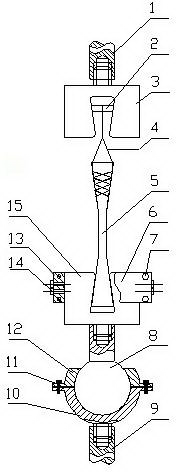

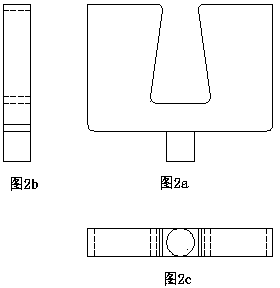

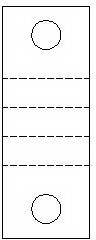

[0019] Such as figure 1 As shown, the present invention includes an upper clamping part and a lower clamping part, and the upper clamping part includes an upper wedge-shaped clamp 3, a circular support beam 2 and a cable 4, and the upper wedge-shaped clamp 3 is connected with the upper pull rod 1 of the testing machine, The circular support beam 2 is horizontally clamped in the wedge-shaped groove of the upper wedge-shaped fixture 3, and the flexible cable 4 used to wind and fix the upper end of the test piece 5 is wound together with the circular support beam 2 and fixed; the lower clamping part includes a lower wedge-shaped Fixture 15, ball stud 8, lower spherical bearing 10 and upper spherical bearing 12, the lower wedge-shaped clamp 15 for clamping the lower end of test piece 5 is connected with ball stud 8, and the ball head of ball stud 8 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com