Preparation method of C/SiC-ZrB2-ZrC ultrahigh-temperature ceramic-based composite material

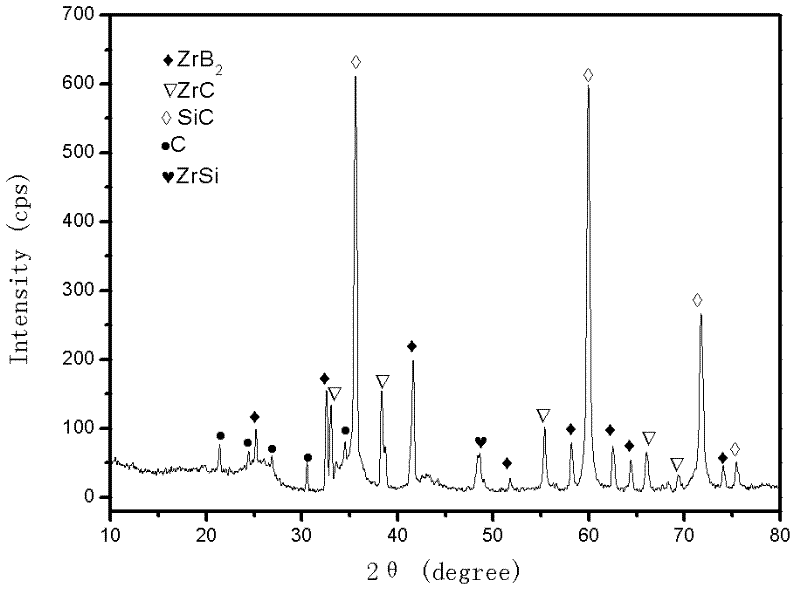

A technology of ultra-high temperature ceramics and composite materials, which is applied in the field of preparation of C/SiC-ZrB2-ZrC ultra-high temperature ceramic matrix composite materials, and can solve the problem of low ZrC volume fraction, weak matrix bonding, poor mechanical properties and ablation properties of materials and other problems, to achieve the effect of improving ablation resistance, high volume content, and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

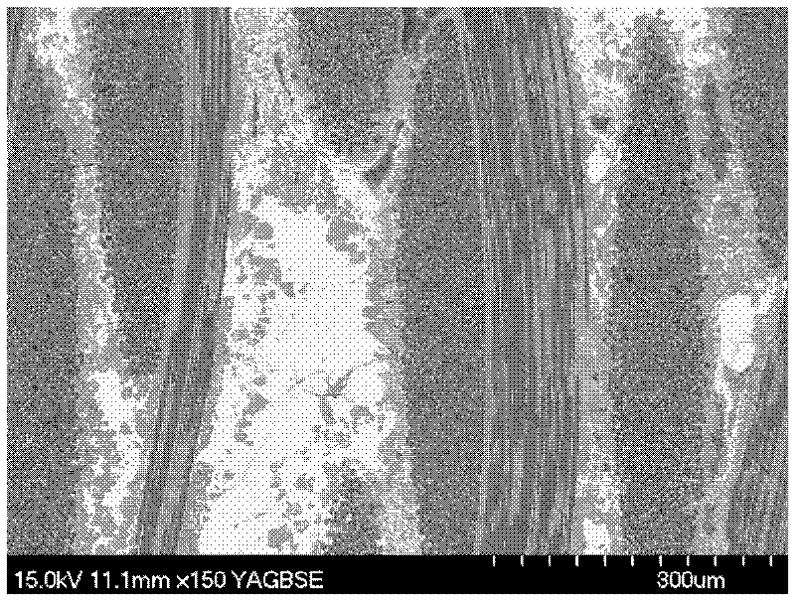

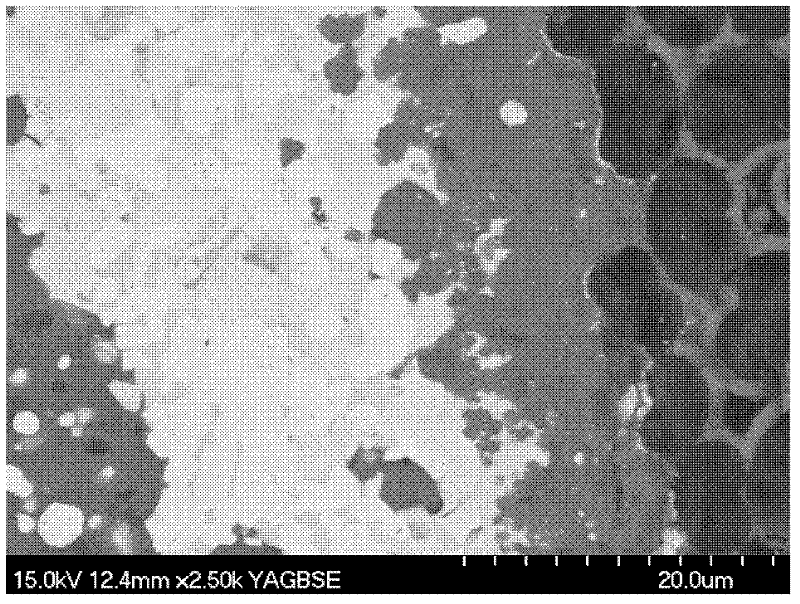

Examples

Embodiment 1

[0028] step 1:

[0029] Preparation of composite material preform: cleaning the C / SiC composite material preform with an open porosity of 20vol%-30vol% by ultrasonic cleaning for at least 30 minutes, and drying in an oven at 80°C-100°C to obtain a C / SiC preform;

[0030] Slurry preparation: Dissolve phenolic resin in absolute alcohol, then add B 4 C powder is added to the alcohol solution of phenolic resin and ball milled on a roller ball mill for more than 24 hours to prepare B 4 C phenolic resin slurry; the proportion of slurry is phenolic resin, hexamethylenetetramine, B 4 The mass ratio of C powder is 10:1:5; the content of absolute alcohol controls the viscosity of the slurry to 50-100mPa·s and measures the viscosity with a rotational viscometer, and controls the dispersibility at 10-11 by adjusting the pH value;

[0031] Step 2: Vacuum pressure impregnation: C / SiC preform and B 4 C phenolic resin slurry is put into the vacuum tank at the same time, but not in contact;...

Embodiment 2

[0035] step 1:

[0036] Preparation of composite material preform: cleaning the C / SiC composite material preform with an open porosity of 20vol%-30vol% by ultrasonic cleaning for at least 30 minutes, and drying in an oven at 80°C-100°C to obtain a C / SiC preform;

[0037] Slurry preparation: Dissolve furan resin in absolute alcohol, then add B 4 C powder is added to the alcohol solution of furan resin and ball milled on a roller ball mill for more than 24 hours to prepare B 4 C furan resin slurry; the proportion of slurry is furan resin, hexamethylenetetramine, B 4 The mass ratio of C powder is 10:1:5; the content of absolute alcohol controls the viscosity of the slurry to 50-100mPa·s and measures the viscosity with a rotational viscometer, and controls the dispersibility at 10-11 by adjusting the pH value;

[0038] Step 2: Vacuum pressure impregnation: C / SiC preform and B 4 C furan resin slurry is placed in a vacuum tank at the same time, but without contact; vacuumize for ...

Embodiment 3

[0042] step 1:

[0043] Preparation of composite material preform: cleaning the C / SiC composite material preform with an open porosity of 20vol%-30vol% by ultrasonic cleaning for at least 30 minutes, and drying in an oven at 80°C-100°C to obtain a C / SiC preform;

[0044] Slurry preparation: mix B 4 C powder is added to 0.5%-1% mass fraction of cellulose sodium (CMC) aqueous solution and ball milled for more than 24 hours to prepare slurry b, B 4 C mass fraction 30%; Phenolic resin, hexamethylenetetramine are dissolved in absolute alcohol to prepare slurry c, phenolic resin mass fraction 50%; The viscosity of slurry is controlled by the content of absolute alcohol or CMC aqueous solution 50- 100mPa·s and measure the viscosity with a rotational viscometer, and control the dispersion by adjusting the pH value at 10-11;

[0045] Step 2: Vacuum pressure impregnation: The C / SiC preform is vacuum pressure impregnated into slurry b and c in turn; the C / SiC preform and slurry b are p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com