Preparation method of Cf/SiC-ZrC-ZrB2 ultrahigh-temperature ceramic-based composite material

A technology of ultra-high temperature ceramics and composite materials, which is applied in the field of improving material ablation resistance, oxidation resistance and mechanical properties. It can solve problems such as uneven distribution and low phase content of ultra-high temperature ceramics, achieve uniform distribution, improve The effect of phase content and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

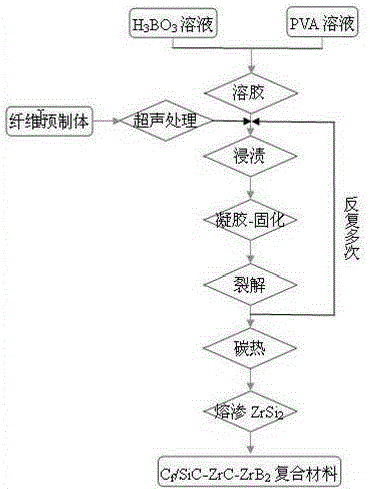

[0054] (1) Prefabricated body treatment: carry out alcohol ultrasonic cleaning on the carbon fiber prefabricated body with an open porosity of 30vol% (the interface is a PyC / SiC composite multilayer interface with a thickness of 500nm), and the cleaning time is 2 hours;

[0055] (2) Preparation of sol solution: H 3 BO 3 , PVA were dissolved in glycerin and deionized water respectively, and 8.0mol / L H 3 BO 3 solution and 2.0mol / L PVA solution, with NH 3 ·H 2 O solution to H 3 BO 3 The pH of the solution was adjusted to 4, and the two solutions were mixed in a molar ratio of H 3 BO 3 / PVA=4 / 10 ratio mixing, reacting at 80°C oil bath temperature for 4-8 hours to obtain a sol solution;

[0056] (3) Vacuum impregnation sol: Under the vacuum condition of -0.08MPa~-0.10MPa, introduce the sol solution in (2) into the C in (1) fIn the preform, heat it at 100°C for 24 hours to obtain C f / polyethyl borate, take it out and put it in an oven to dry at 60°C for 48 hours;

[0057...

Embodiment 2

[0063] Similar to the steps in Example 1, the difference is that the open porosity of the fiber preform is 40% (the interface is a PyC / SiC composite multilayer interface with a thickness of 1000nm), H 3 BO 3 The pH of the solution was adjusted to 5, the molar ratio H 3 BO 3 / PVA=5 / 10, the temperature of the sol-oil bath is 100°C, the gel condition is 110°C for 20 hours, and the gel is dried at 70°C for 36 hours.

Embodiment 3

[0065] Similar to the steps in Example 1, the difference is that the open porosity of the fiber preform is 50% (the interface is a PyC / SiC composite multilayer interface with a thickness of 1500nm), H 3 BO 3 The pH of the solution was adjusted to 6, the molar ratio H 3 BO 3 / PVA=6 / 10, the temperature of the sol-oil bath is 120°C, the gel condition is 120°C for 18 hours, and the gel is dried at 80°C for 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| ablation rate | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com