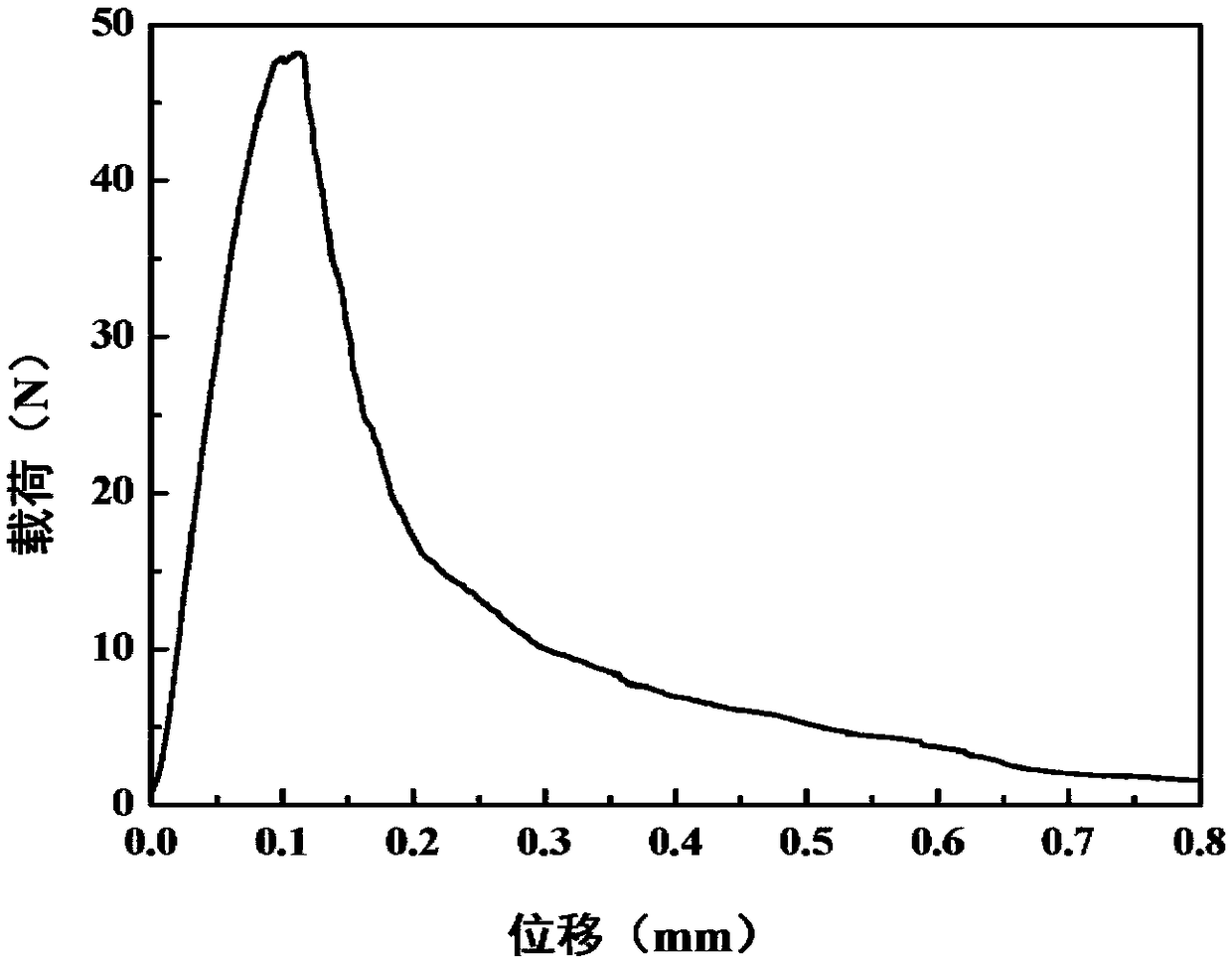

Preparation method of three-dimensional carbon fiber toughened ultrahigh-temperature ceramic-based composite material with high breaking work

A technology of ultra-high temperature ceramics and composite materials, which is applied in the new preparation field of three-dimensional carbon fiber toughened ultra-high temperature ceramic matrix composites, which can solve the problems of low component content and low fracture work, and achieve low equipment cost, reduce pores, optimize The effect of distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Embodiment 1: The preparation method of the three-dimensional carbon fiber toughened ultra-high temperature ceramic matrix composite material with high fracture work in this embodiment is implemented according to the following steps:

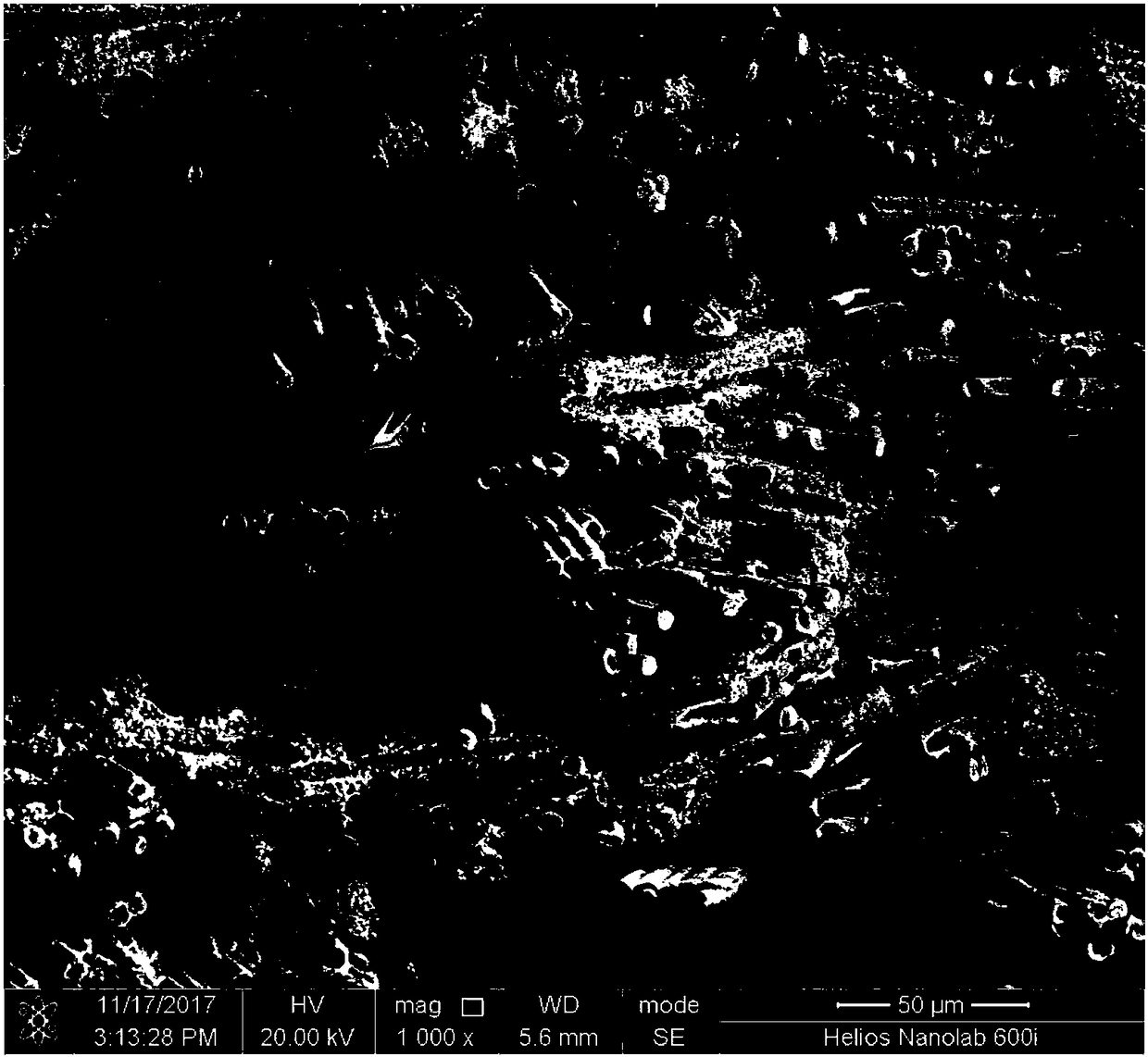

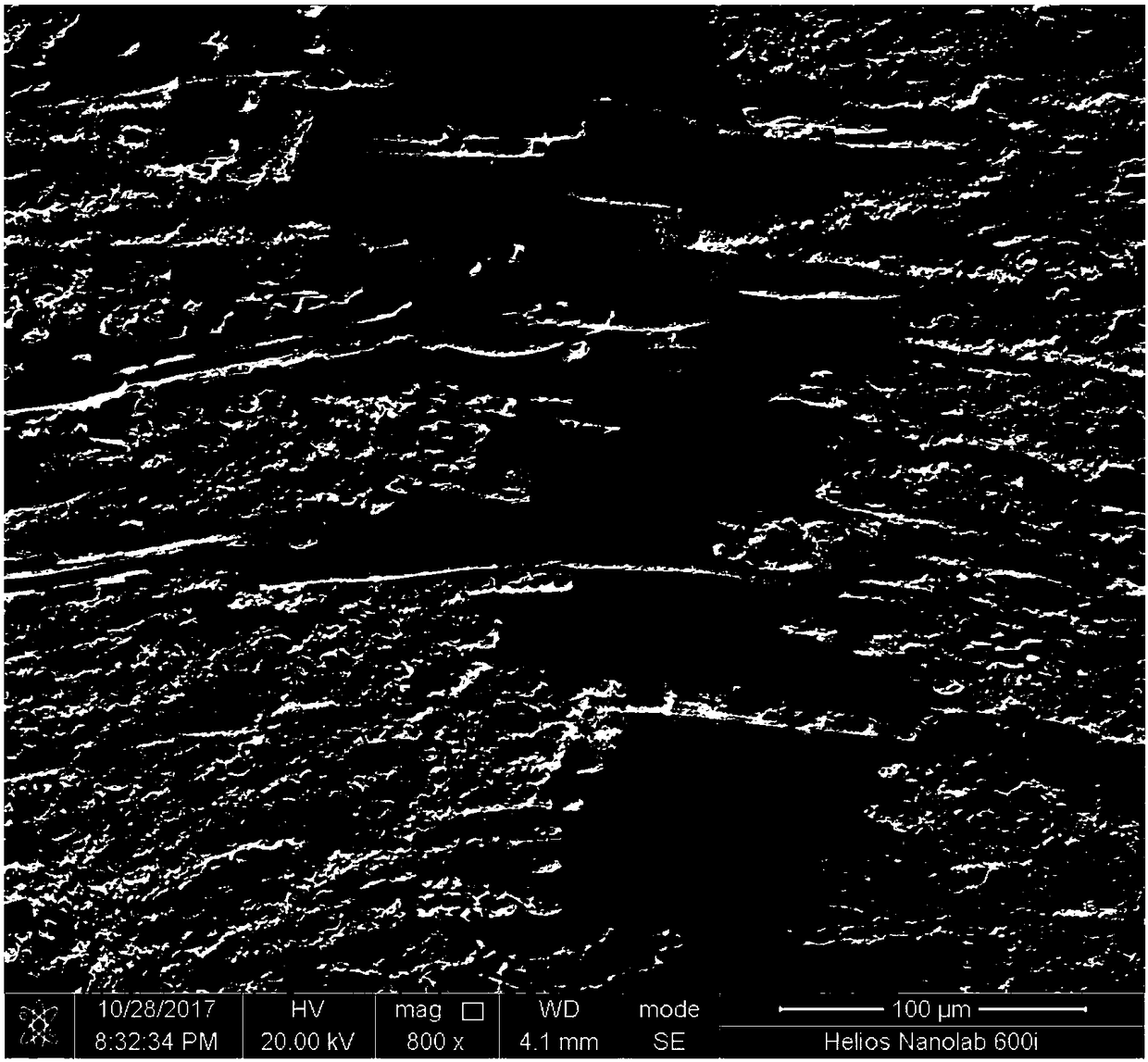

[0021] 1. The three-dimensional carbon fiber braid is placed in a graphite mold, and then placed in a deposition furnace. The mixed gas of propylene and carbon tetrachloride is used as the gas source. 320Pa, carry out vapor deposition, and cool to room temperature to obtain a three-dimensional carbon fiber braided with a pyrolysis carbon coating;

[0022] 2. Mix the ultra-high temperature ceramic powder with absolute ethanol and polyacrylic acid (PAA) into the ball mill, wherein the solid phase content of the ultra-high temperature ceramic powder is 35-45 vol%, and polyacrylic acid (PAA) accounts for the ultra-high temperature ceramic powder. 1% to 2% of the body mass, and then place the ball mill in a planetary ball mill for ball milling...

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the volume ratio of propylene to carbon tetrachloride in step 1 is 0.6-0.7:1.

specific Embodiment approach 3

[0028] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the deposition thickness of the pyrolysis carbon coating in step 1 is 400-600 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com