Plasticized starch textile size and preparation method thereof

A textile size and plasticized starch technology, applied in the field of textile size, can solve the problems of unseen plasticized starch application, unseen starch plasticization, etc., to improve physical and mechanical properties, reduce breaking strength and initial modulus , Improve the effect of fracture work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

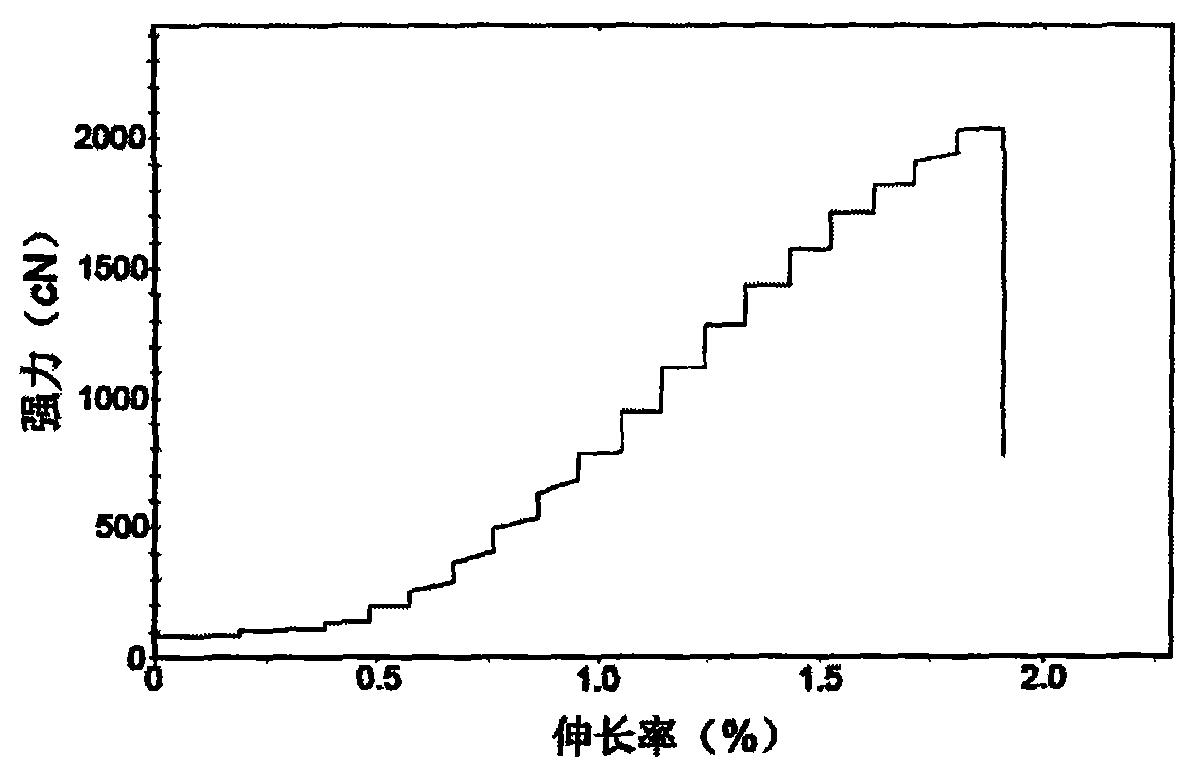

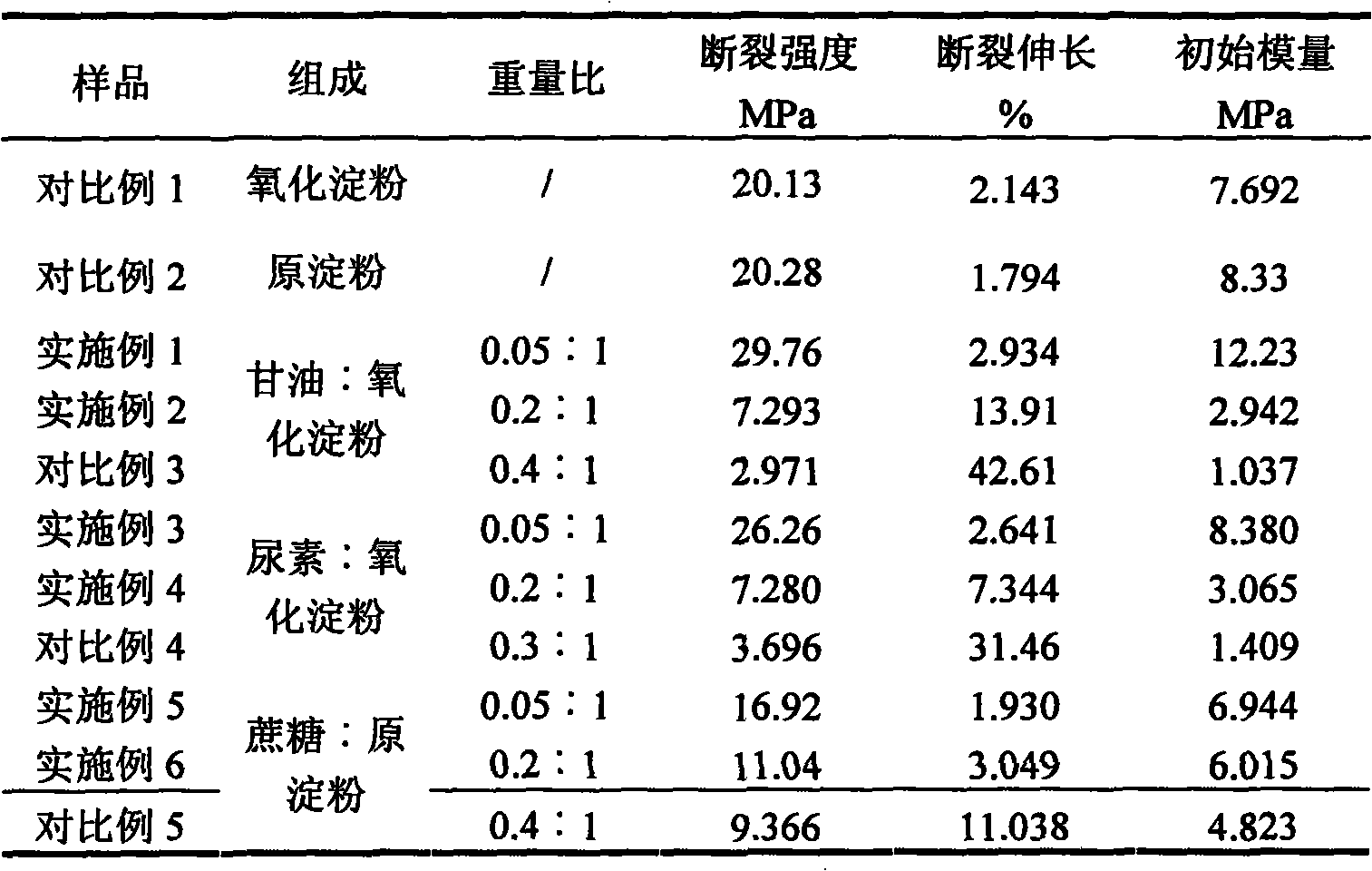

[0041] Add 60% to 75% of 94.75 parts of cold water at room temperature into the cooking tank with a stirrer and a thermometer, start stirring, and then pour 5 parts of corn oxidized starch and 0.25 parts of glycerin (the weight ratio of starch is 0.05:1) into the stirring Stir, heat up and boil in cold water, keep warm for 60-90 minutes, then add the remaining 25-40% of hot water to the specified liquid volume to obtain plasticized starch textile size. The size film is prepared according to the film-forming method of the plasticized starch textile size.

[0042] The elongation and modulus of the size film are shown in Table 1, and the hygroscopicity and crystallinity of the size film are shown in Table 2.

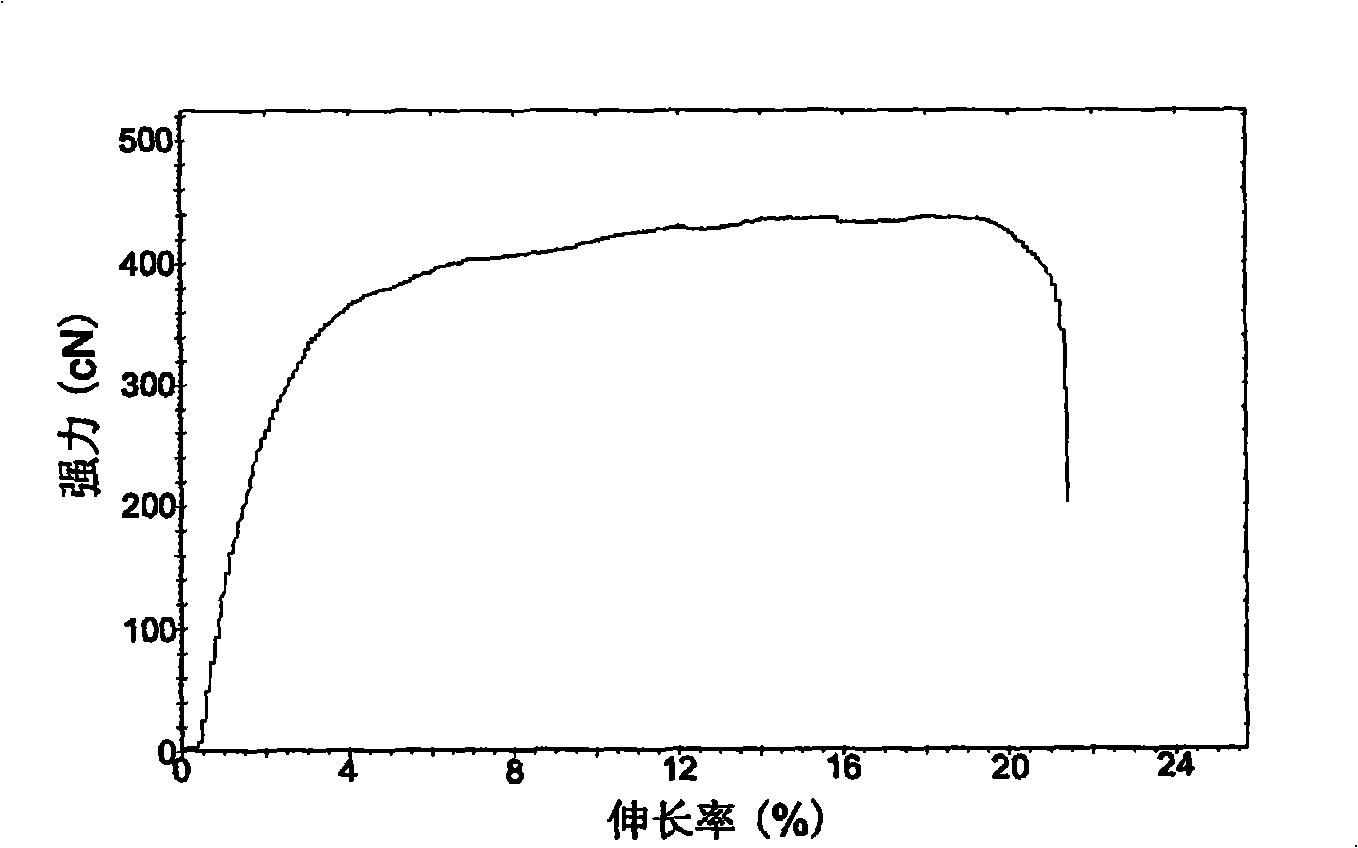

Embodiment 2

[0044] With 5 parts of corn oxidized starch, 1 part of glycerin (0.2:1 to starch weight ratio), 94 parts of tap water, the preparation method of the plasticized starch textile size, the film-forming method and the index test method are the same as in Example 1.

[0045] The measured mechanical properties of the serous film are shown in Table 1. The hygroscopicity and crystallinity of the serous film are shown in Table 2.

Embodiment 3

[0047]With 5 parts of corn oxidized starch, 0.25 part of urea (0.05:1 to starch weight ratio), 94.75 parts of tap water, the pulp cooking process, the pulp film making method and the index test method are the same as in Example 1.

[0048] The measured mechanical properties of the serous film are shown in Table 1. The hygroscopicity and crystallinity of the serous film are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com