Degradation-controllable super absorbent resin and preparation method thereof

A technology of superabsorbent resin and polyether polyurethane, which is applied in the direction of chemical instruments and methods, applications, organic fertilizers, etc., and can solve the problems of lack of controllable degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

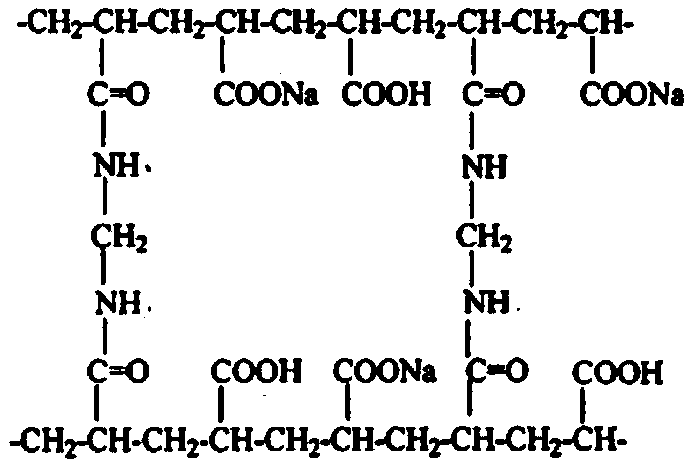

Image

Examples

Embodiment 1

[0045] The preparation method of solid acid catalyst: first ZrOCl 2 ·8H 2 Dissolve O in distilled water, slowly add concentrated ammonia water with a concentration of 10mol / L under stirring, adjust the pH value to 9, and form a gel, then age at room temperature until the upper layer solution is clear, filter with suction, and wash until there is no Cl - was detected, and Zr(OH) was obtained 4 , followed by Zr(OH) 4 Dry in an oven at 105°C for 20 hours, grind into a fine powder, pass through a 120-mesh sieve to obtain a solid powder, and then use dilute H with a concentration of 1.0mol / L 2 SO 4 After impregnation, filter with suction, dry the filter cake in an oven at 100°C for 20 hours, and finally roast it at 650°C for 1 hour, grind it into fine powder, and pass it through a 200-mesh sieve to obtain a solid acid catalyst.

Embodiment 2

[0047] The preparation method of solid acid catalyst: first ZrOCl 2 ·8H 2Dissolve O in distilled water, slowly add concentrated ammonia water with a concentration of 12 mol / L under stirring, adjust the pH value to 9.5, and form a gel, then age at room temperature until the upper layer solution is clear, filter with suction, and wash until there is no Cl - was detected, and Zr(OH) was obtained 4 , followed by Zr(OH) 4 Dry in an oven at 108°C for 22 hours, grind into a fine powder, pass through a 135-mesh sieve to obtain a solid powder, and then use dilute H with a concentration of 1.2mol / L 2 SO 4 After impregnation, filter with suction, dry the filter cake in an oven at 102°C for 22 hours, and finally roast it at 675°C for 2 hours, grind it into fine powder, and pass it through a 225-mesh sieve to obtain a solid acid catalyst.

Embodiment 3

[0049] The preparation method of solid acid catalyst: first ZrOCl 2 ·8H 2 Dissolve O in distilled water, slowly add concentrated ammonia water with a concentration of 13mol / L under stirring, adjust the pH value to 10, and form a gel, then age at room temperature until the upper layer solution is clear, filter with suction, and wash until there is no Cl - was detected, and Zr(OH) was obtained 4 , followed by Zr(OH) 4 Dry in an oven at 110°C for 24 hours, grind into a fine powder, pass through a 150-mesh sieve to obtain a solid powder, and then use dilute H with a concentration of 1.5mol / L 2 SO 4 After impregnation, filter with suction, dry the filter cake in an oven at 105°C for 24 hours, and finally roast it at 700°C for 3 hours, grind it into fine powder, and pass through a 250-mesh sieve to obtain a solid acid catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com