Extremely-high-temperature anti-ablation heat conduction composite material and preparation method thereof

A composite material and anti-ablation technology, which is applied in the field of extremely high-temperature anti-ablation thermally conductive composite materials and their preparation, can solve the problems of insufficient high-temperature ablation resistance, low thermal conductivity, low bending strength, etc. Excellent corrosion performance, high thermal conductivity, excellent high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

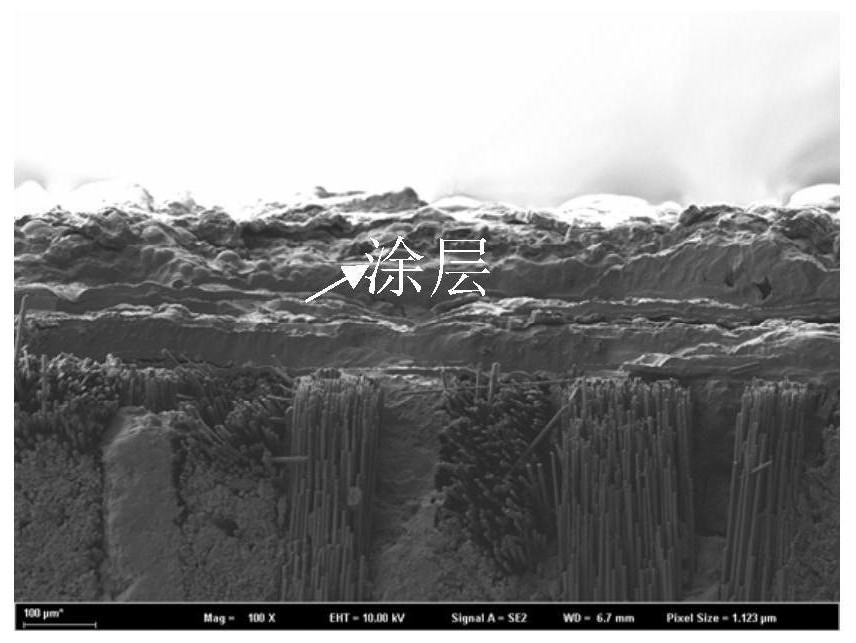

[0033] In a first aspect, the present invention provides a method for preparing an extremely high-temperature ablation-resistant heat-draining composite material, the method comprising the following steps:

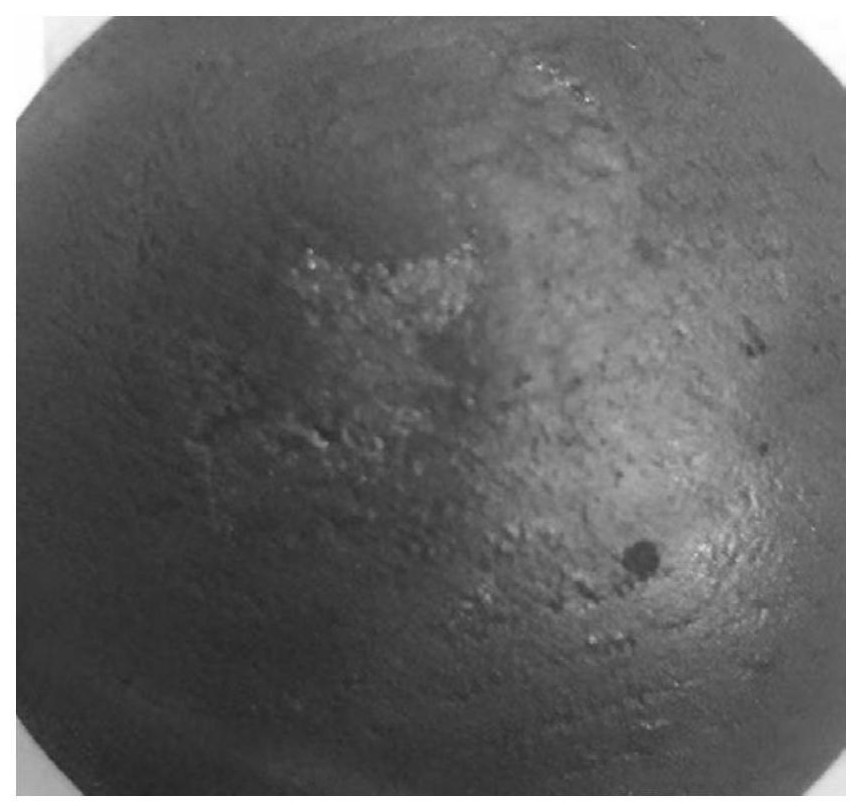

[0034](1) High thermal conductivity carbon fiber (such as mesophase pitch-based high thermal conductivity carbon fiber) and polyacrylonitrile-based carbon fiber (PAN-based carbon fiber) are used to weave a high thermal conductivity carbon fiber prefabricated body; Thermally conductive carbon fiber prefabricated body; In the present invention, when adopting high thermally conductive carbon fiber (such as mesophase pitch-based high thermally conductive carbon fiber) and polyacrylonitrile-based carbon fiber (PAN-based carbon fiber) to be mixed and woven into high thermally conductive carbon fiber preformed body, the high thermally conductive The carbon fiber prefabricated body can be woven with high thermal conductivity carbon fiber and polyacrylonitrile-based carbon fiber thr...

Embodiment 1

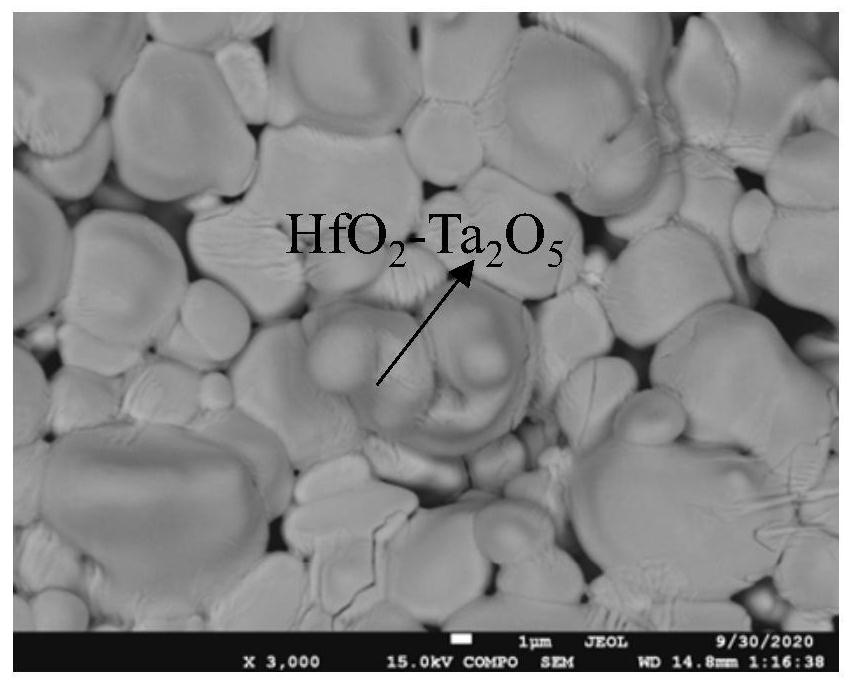

[0062] A method for preparing an extremely high-temperature ablation-resistant heat-draining composite material, the specific steps of which are:

[0063] ① Weaving of high thermal conductivity carbon fiber prefabricated body: three-way orthogonal structure is adopted, 2K mesophase pitch-based high thermal conductivity carbon fiber is used in the thermal conductivity direction (marked as X direction), and PAN-based T700 is used in the other two directions (Y direction and Z direction) The carbon fiber is mixed and woven, the mesophase pitch-based high thermal conductivity carbon fiber accounts for 82% of the volume fraction of the total carbon fiber in the high thermal conductivity carbon fiber preform, and the volume density of the high thermal conductivity carbon fiber preform is 1.1g / cm 3 .

[0064] ②Preparation of the carbon interface layer: first prepare a pyrolytic carbon interface layer on the fiber surface of the high thermal conductivity carbon fiber prefabricated bod...

Embodiment 2

[0069] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0070] Embodiment 2 does not comprise step ④, does not carry out HfC-TaSi 2 Preparation of ultra-high temperature ceramic coatings.

[0071] The performance indexes of the materials finally prepared in this embodiment are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com