Ceramic-able phenolic resin, and preparation method and application thereof

A phenolic resin and ceramization technology, applied in the field of ceramizable phenolic resin and its preparation, can solve the problems of high material porosity, long molding cycle and high manufacturing cost, and achieve excellent process performance, high carbon residue rate and heat resistance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

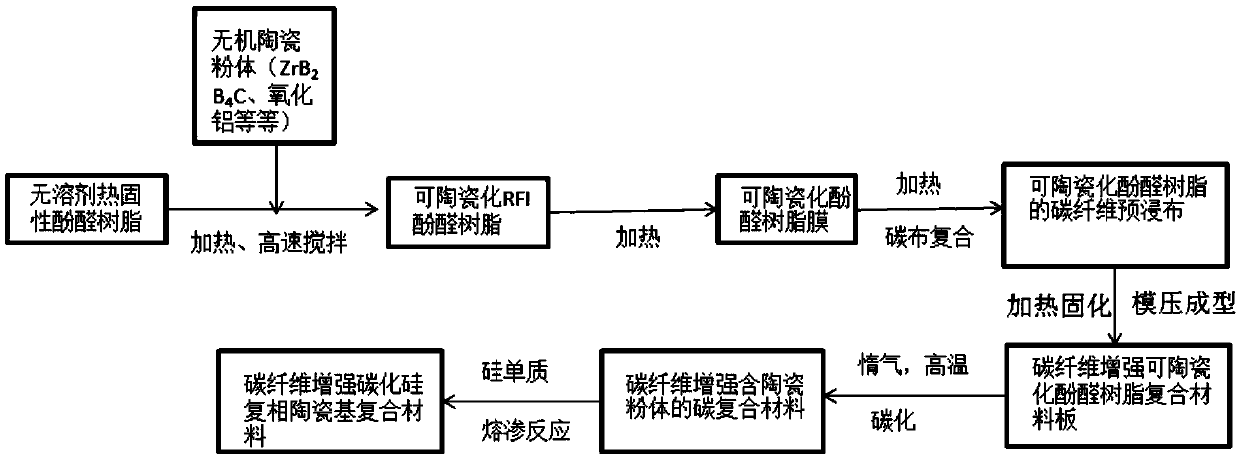

Method used

Image

Examples

preparation example Construction

[0066] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0067] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

[0068] The carbon cloth used in the following examples was purchased from the carbon cloth of the brand T300 produced by Toray Corporation of Japan.

Embodiment 1

[0070] Preparation of ceramizable phenolic resin CPF-1 and carbon fiber reinforced silicon carbide ceramic matrix composites

[0071] (1) Preparation of ceramizable phenolic resin CPF-1

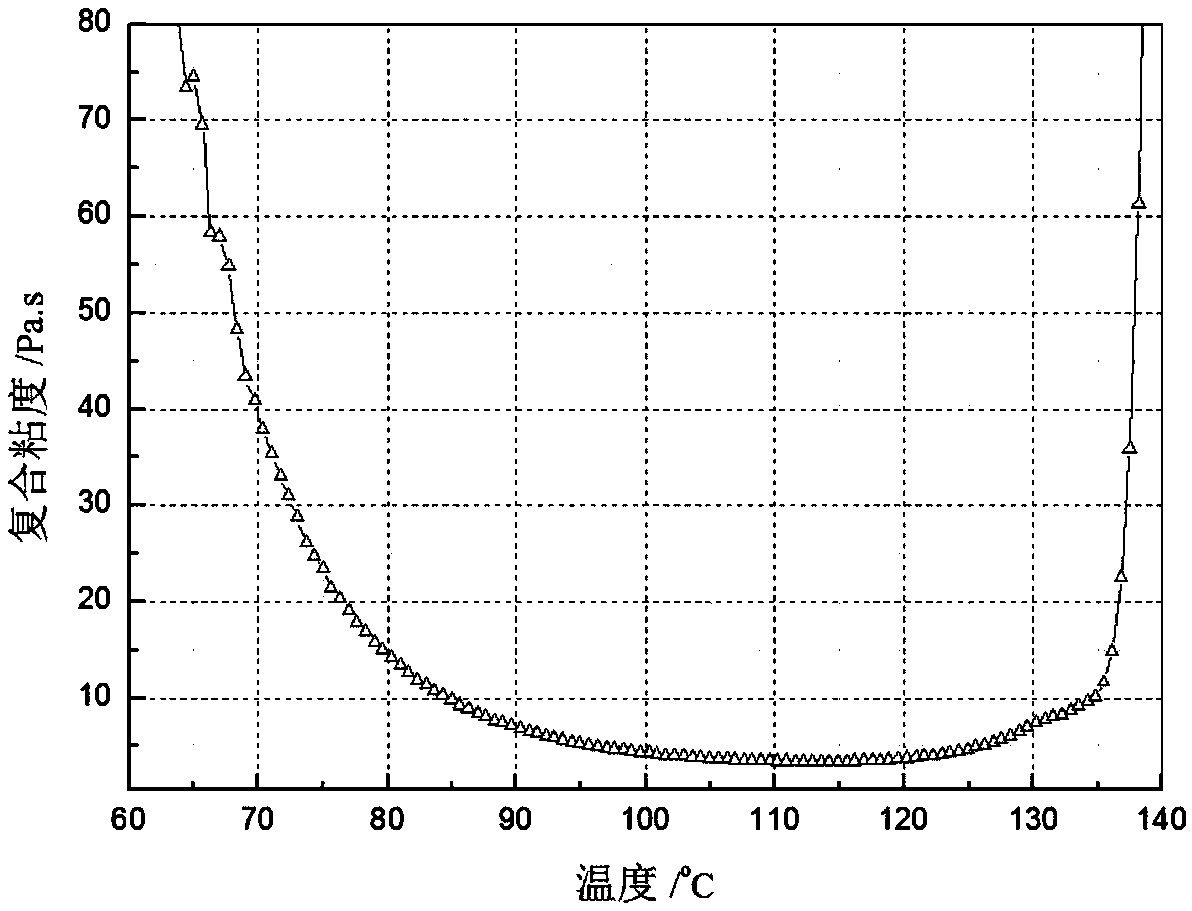

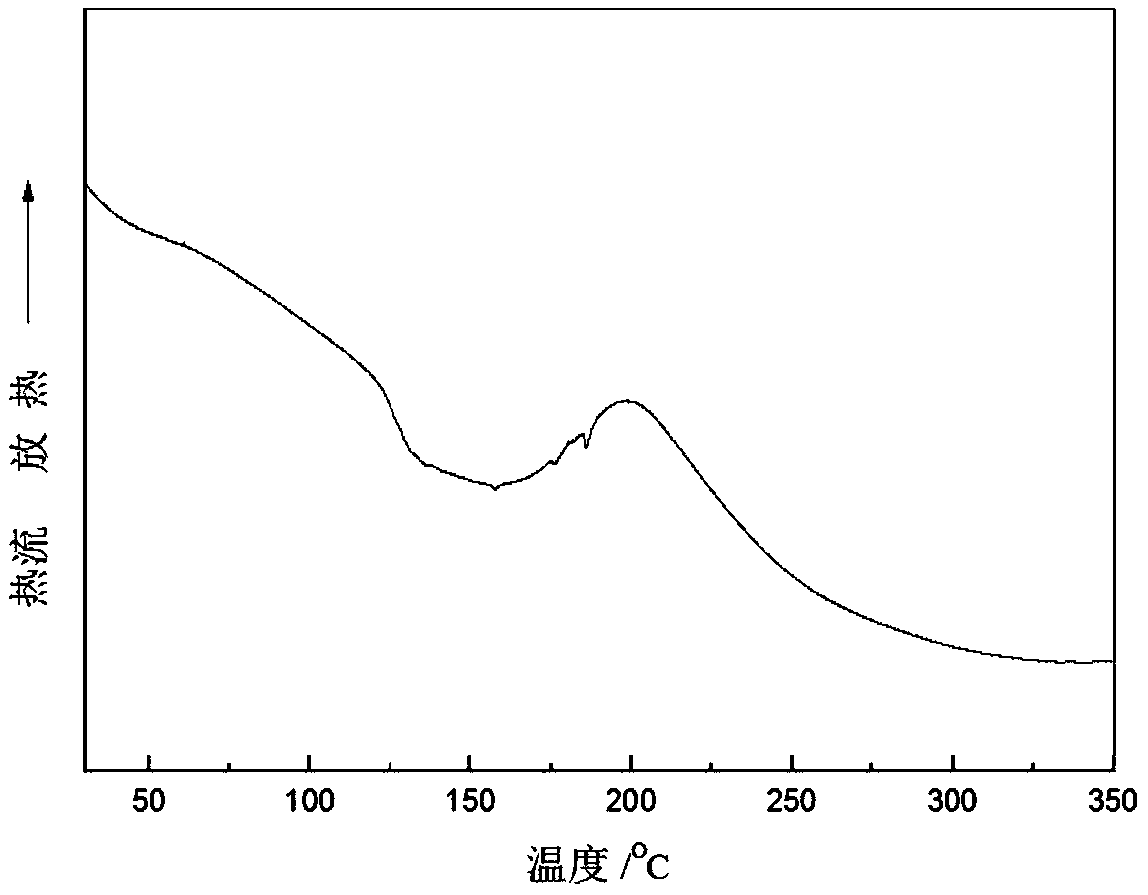

[0072] This embodiment uses a solvent-free, wide processing window thermosetting sodium phenolic resin with a solid content of 85.3% and a rotational viscosity at 80° C. of 300 mPa.s. Take 100 grams of the resin and add it into a three-necked flask with a volume of 500 mL, and heat up to a material temperature of 60° C. while stirring. Add 5 grams of boron carbide powder (purity ≥ 98%, particle size less than 1 micron) and 55 grams of aluminum oxide powder (purity ≥ 98%, particle size is about 200nm) into the resin, at 60 ° C Stir at high speed for 15 minutes until the materials are evenly mixed. Pour the mixed system into an aluminum foil box while it is hot, and cool it rapidly to obtain 155 grams of ceramizable phenolic resin CPF-1 with a uniform composition, which is sealed and frozen. ...

Embodiment 2

[0077] Preparation of ceramizable phenolic resin CPF-2 and alumina fiber reinforced silicon carbide ceramic matrix composites

[0078] (1) Preparation of ceramizable phenolic resin CPF-2

[0079] In this embodiment, a solvent-free, wide-processing-window thermosetting aminophenol-formaldehyde resin is used, with a solid content of 92.25% and a rotational viscosity at 80° C. of 2050 mPa.s. Take 100 grams of the resin and add it into a three-necked flask with a volume of 500 mL, and heat up to a material temperature of 85° C. while stirring. 50 grams of zirconium diboride powder (purity greater than or equal to 98%, particle size less than 5 microns), 10 grams of boron carbide powder (purity greater than or equal to 98%, particle size less than 1 micron), 10 grams of zirconium carbide Powder (purity greater than ≥ 98%, particle size less than 5 microns), 10 grams of tantalum carbide powder (purity greater than ≥ 98%, particle size less than 5 microns) and 10 grams of hafnium ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| gel time | aaaaa | aaaaa |

| gel time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com