Cf/HfC-SiC ultrahigh temperature ceramic matrix composite material and preparation method thereof

A technology of ultra-high temperature ceramics and composite materials, applied in the field of ceramic matrix composite material preparation, can solve the problems of fiber/interface damage, metal residues, affecting the mechanical properties of composite materials, etc., achieve uniform filling, low silicon/carbon residues, and eliminate defects effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

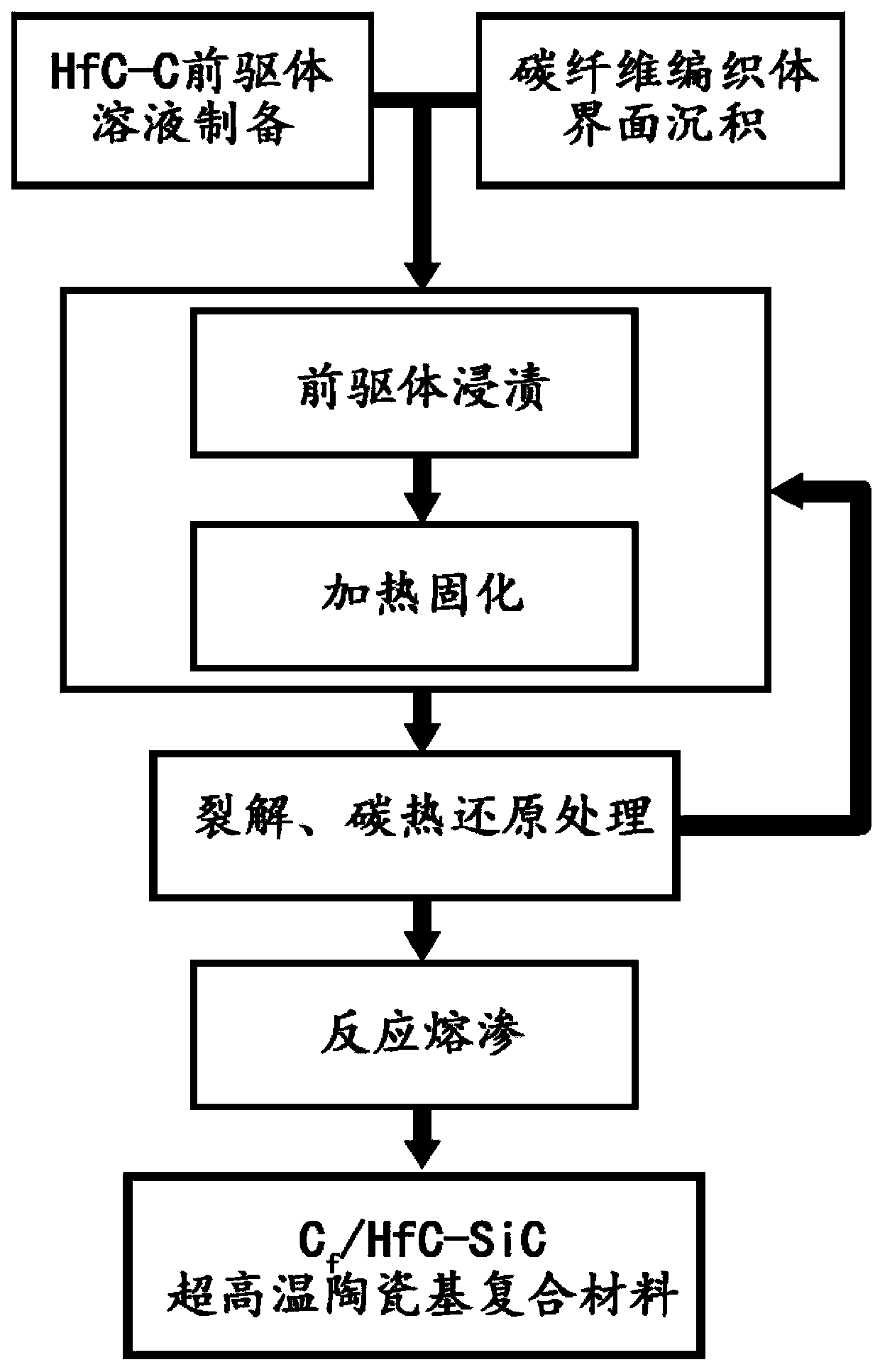

Method used

Image

Examples

Embodiment 1

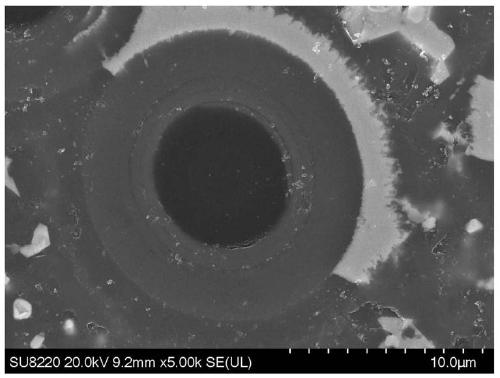

[0039] (1) Carbon fiber preform treatment: PyC / SiC composite multilayer interface is deposited on the surface of the carbon fiber preform fiber by chemical vapor deposition, with a thickness of 500 nm. The open porosity of the obtained carbon fiber preform is 65 vol%;

[0040] (2) Preparation of HfC-C precursor solution: Dissolve hafnium tetrachloride in deionized water at a molar concentration of hafnium element 2mol / L, and then add sucrose in a ratio of 8:3 in the molar ratio of hafnium tetrachloride to sucrose (to make hafnium The ratio of the element to the carbon element is 1:4.5). After dissolution, add polyvinylpyrrolidone with a mass of 2wt% deionized water and stir for 6 hours until a uniform solution is formed to obtain a HfC-C precursor solution;

[0041] (3) Vacuum impregnation of HfC-C precursor solution: the precursor solution obtained in step (2) is introduced into the carbon fiber preform obtained in step (1) by vacuum impregnation, the vacuum degree is -0.08MPa, an...

Embodiment 2

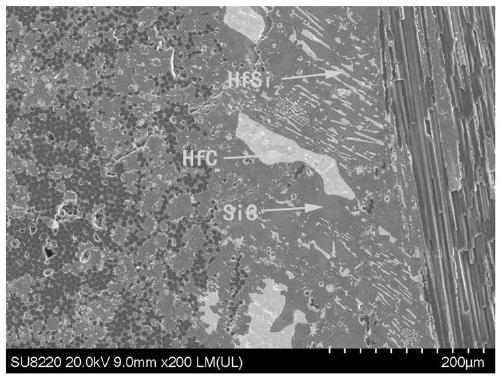

[0047] The steps are similar to those in Example 1, except that the carbon fiber preform has a PyC / SiC interface layer with an interface thickness of ~1500 nm. The open porosity of the obtained carbon fiber preform was 56 vol%. In the precursor solution used, the hafnium source compound is hafnium oxychloride monohydrate, the carbon source compound is sucrose, and the molar ratio of the hafnium source compound to the carbon source compound is 2:1. C prepared in Example 2 f The volume ratio of the HfC-SiC phase in the HfC-SiC ultra-high temperature ceramic matrix composite is ~1:4, the open porosity is 6%, and the bending strength is 248MPa.

Embodiment 3

[0049] The steps are similar to those in Example 1, except that the interface of the carbon fiber preform is BN with a thickness of ~500nm. The open porosity of the obtained carbon fiber preform was 65 vol%. In the precursor solution used, the hafnium source compound is hafnium oxychloride monohydrate, the carbon source compound is sucrose, the stabilizer used is polyacrylic acid, the addition amount of stabilizer is 5wt% of the solvent mass, the pyrolysis temperature is 1000°C, and the time is 1 hour. C prepared in Example 3 f / HfC-SiC ultra-high temperature ceramic matrix composites, the volume ratio of HfC-SiC phase is ~1:2.5, the open porosity is 8%, and the bending strength is 203MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com