Preparation method of ZrB2-ZrC-based ultrahigh-temperature-resistant ceramic

A technology of high-temperature ceramics, zrb2-zrc, applied in the field of ceramic materials, can solve problems such as restrictions on popularization and application, and achieve the effects of lower process temperature, low cost, and low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

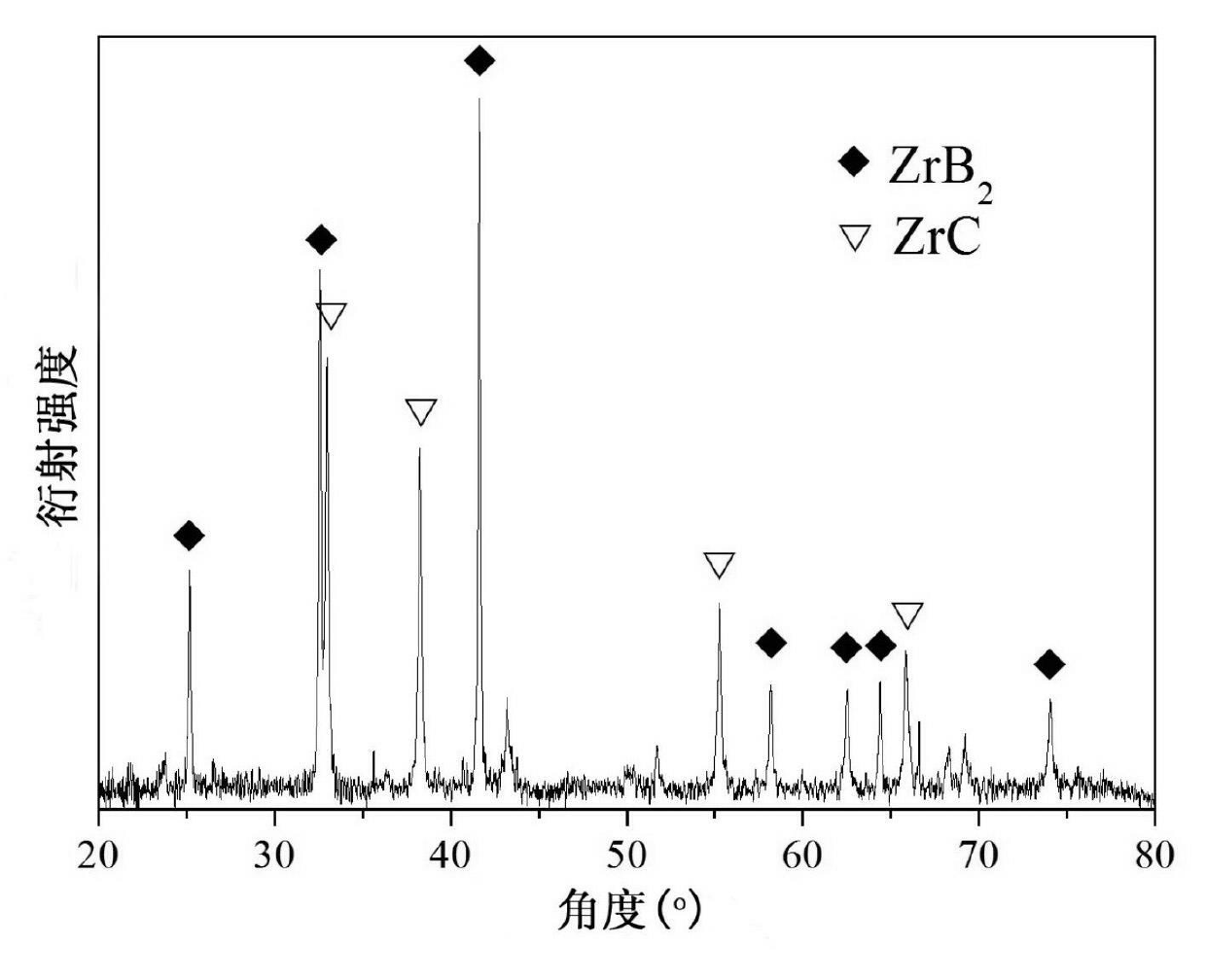

[0028] A kind of infiltration reaction of the present invention prepares ZrB 2 -The method for ZrC-based ultra-high temperature resistant ceramics, comprising the following steps:

[0029] (1) Prepare the green body: weigh B with a mass ratio of 19:1 4 C powder and binder polycarbosilane, mix the weighed raw materials through ball milling, put the mixed powder in a mold, keep it warm at 120°C for 6 hours, and obtain a green body after cross-linking molding;

[0030] (2) Firing the porous rigid preform: pyrolyze the above-mentioned green body under vacuum at 900°C and keep it warm for 1 hour to obtain the porous rigid preform;

[0031] (3) Preparation of zirconium-containing alloys: using metal zirconium and metal copper with a mass ratio of 1:1 as the main raw materials, through vacuum induction melting, to prepare zirconium-containing alloys;

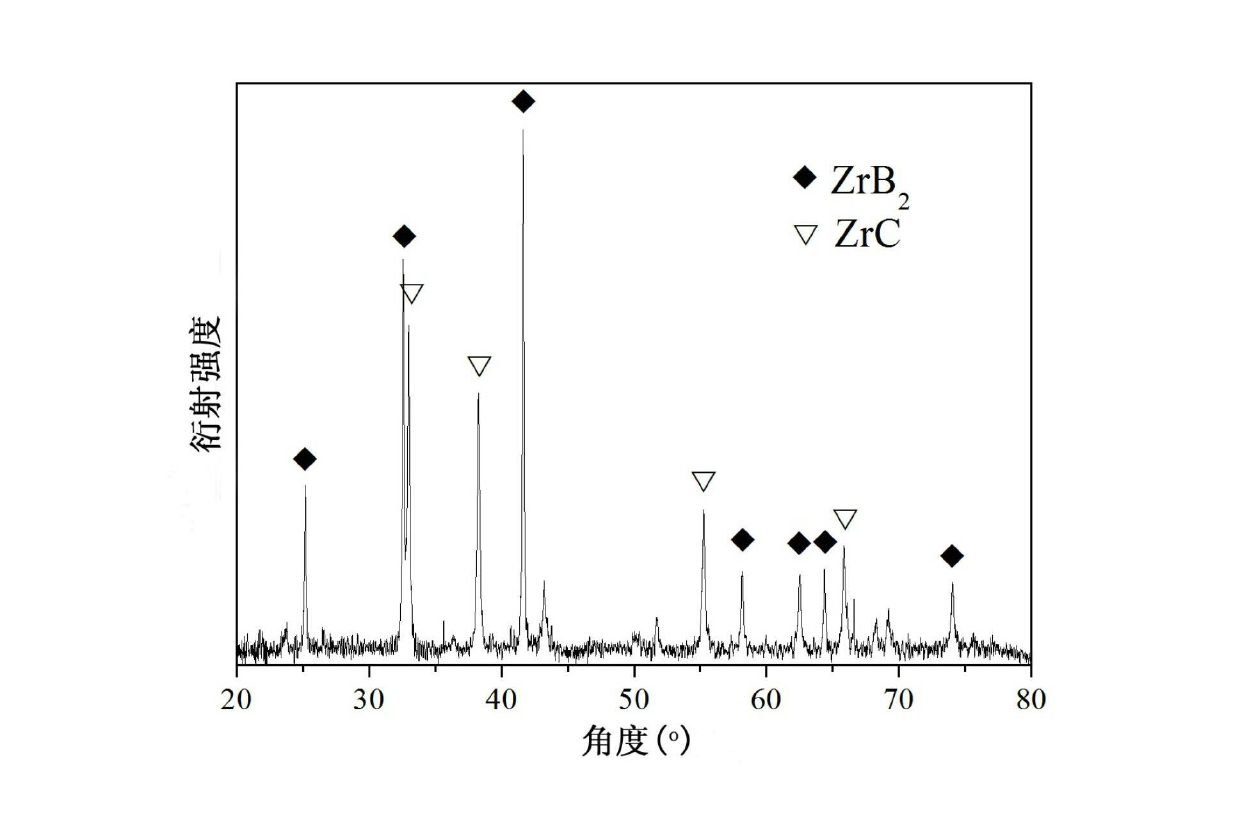

[0032] (4) Infiltration reaction: take the porous rigid prefabricated body prepared above as the base material, and the zirconium-c...

Embodiment 2

[0037] A kind of infiltration reaction of the present invention prepares ZrB 2 -The method for ZrC-based ultra-high temperature resistant ceramics, comprising the following steps:

[0038] (1) Prepare the green body: weigh B with a mass ratio of 15:4:1 4 C powder, pore-forming agent flour and binder polycarbosilane are mixed by ball milling the weighed raw materials, and molded under a pressure of 100 MPa to obtain a green body;

[0039] (2) Firing the porous rigid preform: the above-mentioned green body was cracked at 1600°C under vacuum conditions, and kept for 0.5h to obtain a porous rigid preform;

[0040] (3) Preparation of zirconium-containing alloys: using metal zirconium and metal copper with a mass ratio of 3:1 as the main raw materials, through arc melting, to prepare zirconium-containing alloys;

[0041] (4) Infiltration reaction: take the porous rigid prefabricated body prepared above as the base material, and the zirconium-containing alloy as the infiltration agen...

Embodiment 3

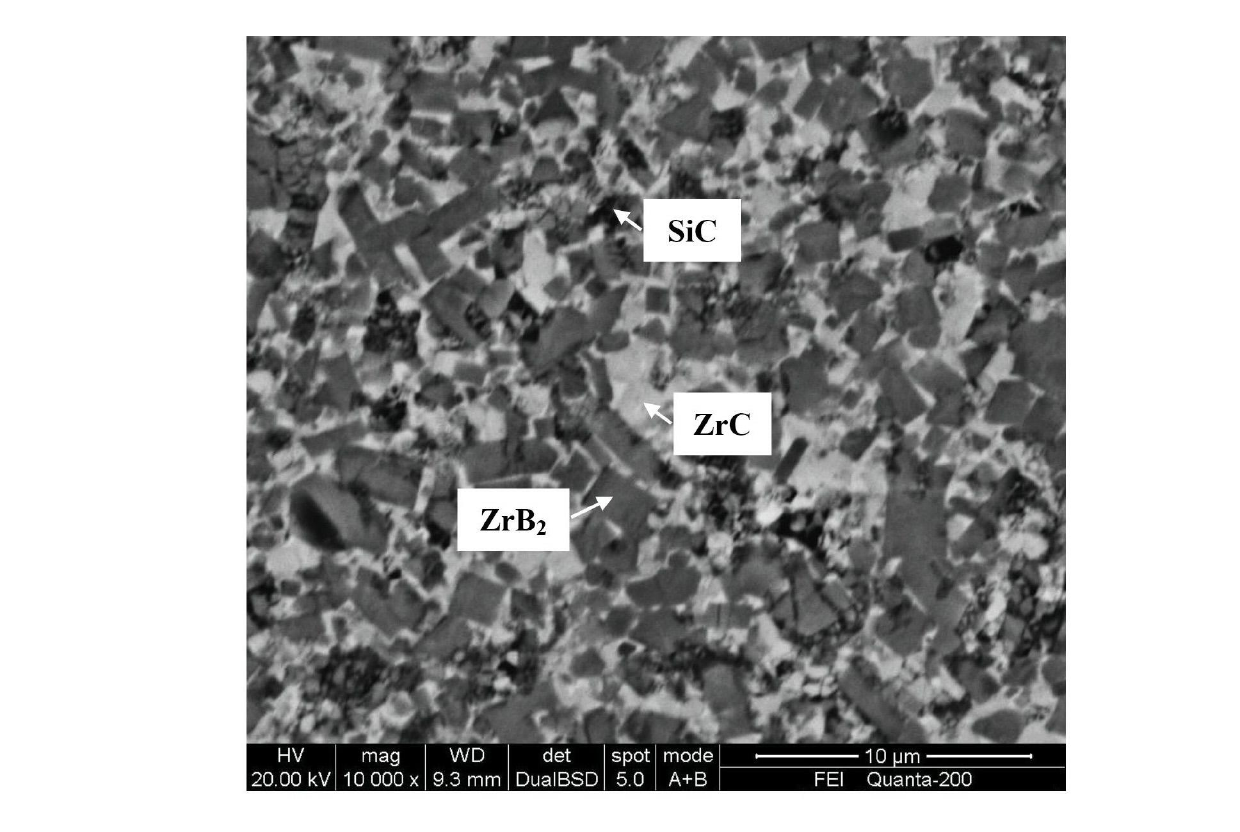

[0045] A kind of infiltration reaction of the present invention prepares ZrB 2 -The method for ZrC-based ultra-high temperature resistant ceramics, comprising the following steps:

[0046] (1) Prepare the green body: weigh B with a mass ratio of 5:1:1:3 4 C powder, filler SiC powder, pore-forming agent flour and binder polycarbosilane, mixing the weighed raw materials by ball milling, and molding under a pressure of 200MPa to obtain a green body;

[0047] (2) Firing the porous rigid preform: the above-mentioned green body is subjected to high temperature cracking at 1600°C under vacuum conditions and kept for 1 hour to obtain a porous rigid preform;

[0048] (3) Preparation of zirconium-containing alloys: using metal zirconium and elemental silicon with a mass ratio of 97:3 as the main raw materials, through electric arc melting, to prepare zirconium-containing alloys;

[0049] (4) Infiltration reaction: take the porous rigid prefabricated body prepared above as the base mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Wire ablation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com