Preparation method of lamellar silicon carbide/zirconium carbide ultrahigh-temperature ceramic

A technology of ultra-high-temperature ceramics and silicon carbide, which is applied in the field of preparation of ultra-high-temperature ceramics, can solve problems such as easy generation of air bubbles and affect material properties, and achieve the effects of preventing stress from spreading, good dispersion, and avoiding air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

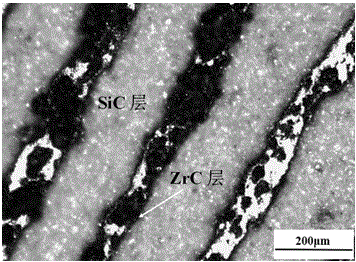

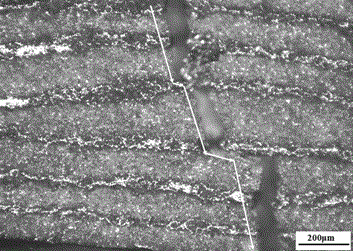

[0029] Mix 45g of silicon carbide powder with a particle size of about 800nm, 12g of polymethacrylate, 12g of polyethylene glycol, and 231g of absolute ethanol in a beaker, and ultrasonically disperse it in a water bath at 60°C for 1 hour. Add 3g of n-octanol to the mixture, mix well, and pour the slurry into a glass mold. After drying at room temperature for 6 hours, a silicon carbide cast sheet is obtained, and the thickness of the layer is about 0.8mm. Zirconium carbide (zirconium carbide powder) is obtained by the same method particle size of 30nm) casting sheet. Silicon carbide casting sheets and zirconium carbide casting sheets are alternately stacked and put into a vacuum sintering furnace for debinding. The heating rate is 10°C / min, and the temperature is kept at 600°C for 1.5 hours to obtain layered silicon carbide / zirconium carbide Green body of ultra-high temperature ceramics. Finally, the green body was put into a graphite mold and sintered in a vacuum hot-pressin...

Embodiment 2

[0031] Mix 45g of silicon carbide powder with a particle size of about 10μm, 7.5g of polymethacrylate, 7.5g of polyethylene glycol, and 240g of absolute ethanol in a beaker, and ultrasonically disperse it in a water bath at 60°C for 1 hour. Add 4.5g n-octanol in the beaker, mix well, obtain slurry and pour in the glass mould, after drying at room temperature for 6 hours, obtain silicon carbide casting sheet, layer thickness is 0.6mm, and similar method makes zirconium carbide (zirconium carbide Powder particle size is 25nm) casting sheet. Silicon carbide casting sheets and zirconium carbide casting sheets are alternately stacked and placed in a vacuum sintering furnace for debinding. The heating rate is 8°C / min, and they are kept at 600°C for 1.2 hours to obtain layered silicon carbide / zirconium carbide Green body of ultra-high temperature ceramics. Finally, the green body was put into a graphite mold and sintered in a vacuum hot-pressing sintering furnace. The sintering temp...

Embodiment 3

[0033]Mix 45g of silicon carbide powder with a particle size of about 5μm, 15g of polymethacrylate, 15g of polyethylene glycol, and 225g of absolute ethanol in a beaker, and ultrasonically disperse it in a water bath at 60°C for 1 hour. Add 3.5g n-octanol to the mixture, mix well, and pour the slurry into a glass mould. After drying at room temperature for 6 hours, a silicon carbide casting sheet is obtained, and the layer thickness is 0.7mm. The same method is used to obtain zirconium carbide (zirconium carbide powder Particle size is 35nm) casting sheet. Silicon carbide casting sheets and zirconium carbide casting sheets are alternately stacked and placed in a vacuum sintering furnace for debinding. The heating rate is 5°C / min, and they are kept at 600°C for 1.0 hours to obtain layered silicon carbide / zirconium carbide Green body of ultra-high temperature ceramics. Finally, the green body was put into a graphite mold and sintered in a vacuum hot-pressing sintering furnace. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com