Ceramic fiber catalytic filter element and integrated preparation method thereof

A ceramic fiber and ceramic short fiber technology, which is applied in the field of flue gas purification, can solve the problems of high cost, low porosity, low mechanical strength, etc., and achieve low filtration resistance, high porosity, mechanical strength and improved wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

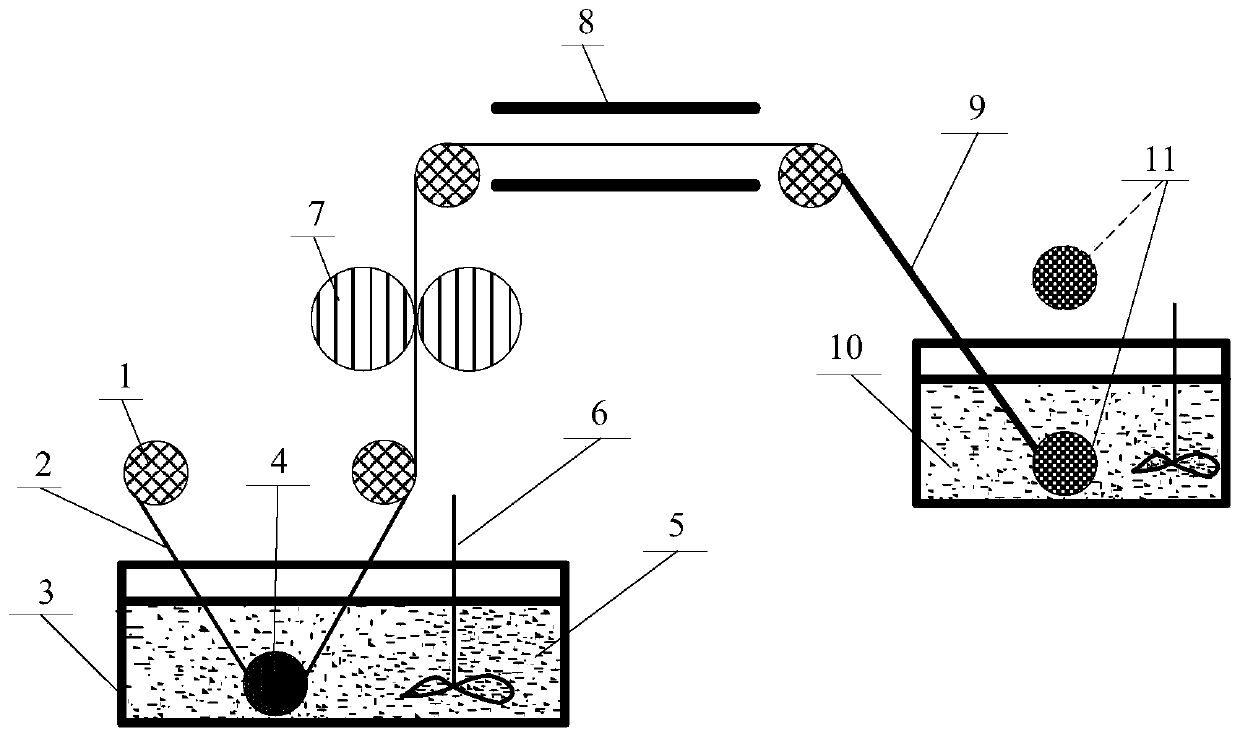

Image

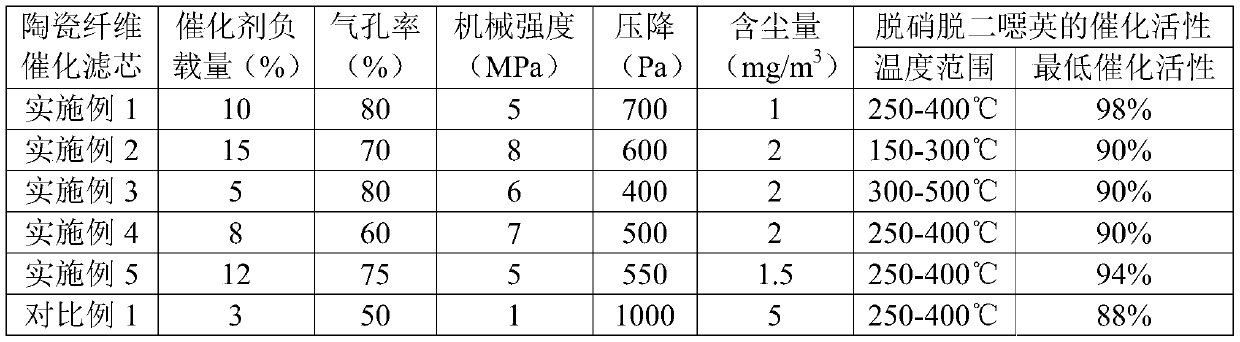

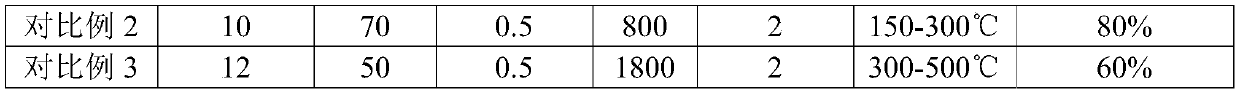

Examples

Embodiment 1

[0070] An integrated preparation method for a ceramic fiber catalytic filter element, comprising the steps of:

[0071](1) Preparation of catalyst slurry: the vanadium-titanium series catalyst, polyvinyl alcohol and water that are composed of 10% vanadium pentoxide, 10% molybdenum trioxide and 80% titanium dioxide are mixed uniformly to obtain a solid particle size of 0.1 μm Catalyst slurry 5, wherein the mass concentration of vanadium-titanium catalyst is 40%, and the mass concentration of polyvinyl alcohol is 5%;

[0072] Preparation of ceramic short fiber slurry: mix aluminum silicate fiber, vinyl bis stearamide, silica sol and water, and prepare ceramic short fiber slurry 10 with a fiber diameter of 0.1 μm and a fiber length of 2 μm by ball milling, in which silicon The mass concentration of aluminum acid fiber is 20%, the mass concentration of vinylbisstearamide is 1%, and the mass concentration of silica sol is 5%;

[0073] (2) Glass fiber cloth 2 with a through-porosit...

Embodiment 2

[0076] An integrated preparation method for a ceramic fiber catalytic filter element, comprising the steps of:

[0077] (1) Preparation of catalyst slurry: the manganese-based catalyst, polyvinyl alcohol and water with a mass composition of 60% manganese tetraoxide and 40% manganese dioxide are mixed uniformly to obtain a catalyst slurry 5 with a solid particle size of 1 μm, wherein The mass concentration of manganese series catalyst is 30%, and the mass concentration of polyvinyl alcohol is 20%;

[0078] Preparation of ceramic short fiber slurry: high alumina fiber, glyceryl monostearate, aluminum sol and water were mixed, and prepared by stirring to obtain ceramic short fiber slurry 10 with a fiber diameter of 1.5 μm and a fiber length of 6 μm, in which high aluminum The mass concentration of fiber is 3%, the mass concentration of glyceryl monostearate is 5%, and the mass concentration of aluminum sol is 10%;

[0079] (2) The high silica fiber cloth 2 with a through-porosit...

Embodiment 3

[0082] An integrated preparation method for a ceramic fiber catalytic filter element, comprising the steps of:

[0083] (1) Preparation of catalyst slurry: Mix the iron oxide-based catalyst, polyacrylate and water with a mass composition of 80% ferric oxide and 20% copper oxide, to obtain a catalyst slurry 5 with a solid particle size of 0.5 μm , wherein the mass concentration of iron oxide catalyst is 40%, and the mass concentration of polyacrylate is 15%;

[0084] Preparation of short ceramic fiber slurry: mix quartz fiber, glyceryl tristearate, aluminum sol and water, and prepare by ball milling to obtain short ceramic fiber slurry 10 with a fiber diameter of 0.5 μm and a fiber length of 3 μm, wherein the quartz fiber The mass concentration is 20%, the mass concentration of glyceryl tristearate is 3%, and the mass concentration of aluminum sol is 8%;

[0085] (2) The ceramic fiber cloth 2 with a porosity of 60%, a pore diameter of 0.5 mm, a fiber diameter of 10 μm, and a w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com