Method for producing electronic-grade nitric acid

A production method and electronic-grade technology, applied in the directions of nitric acid, nitrogen oxides/oxyacids, etc., can solve the problems of uneconomical, troublesome exhaust gas treatment, strong corrosiveness and instability of concentrated nitric acid, etc., so as to reduce pressure and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

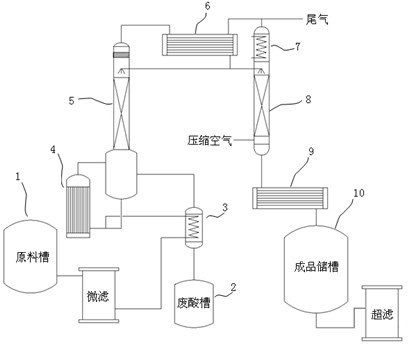

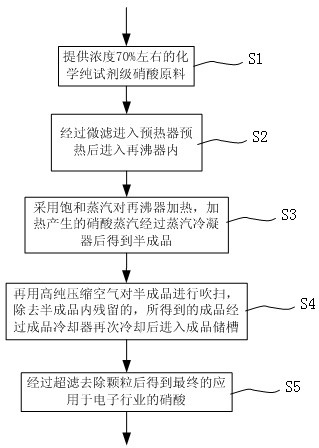

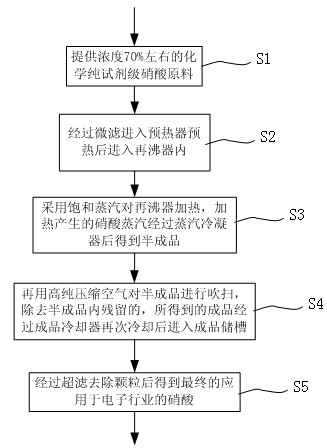

[0024] figure 1 It is a schematic diagram of an electronic grade nitric acid production device of the present invention; figure 2 It is a flowchart of the electronic grade nitric acid production method of the present invention.

[0025] See figure 1 and figure 2 , the electronic grade nitric acid production method provided by the invention, comprises the steps:

[0026] S1: Provide chemically pure reagent grade nitric acid raw material with a concentration of about 70%, which is stored in stainless steel raw material tank 1;

[0027] S2: The above-mentioned nitric acid raw material is filtered through a micron-level PP material filter element, preheated by the preheater 3 at a flow rate of 120-180kg / h, and then enters the reboiler 4. The preheater 3 is used to treat the normally discharged nitric acid waste acid to The nitric acid raw material is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com