Technique for preparing sandwich ice creams

A preparation process and sandwich technology, applied in frozen desserts, food science, applications, etc., can solve the problems of low yield, inability to mass-produce and sell products, and affect the appearance of products, and achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

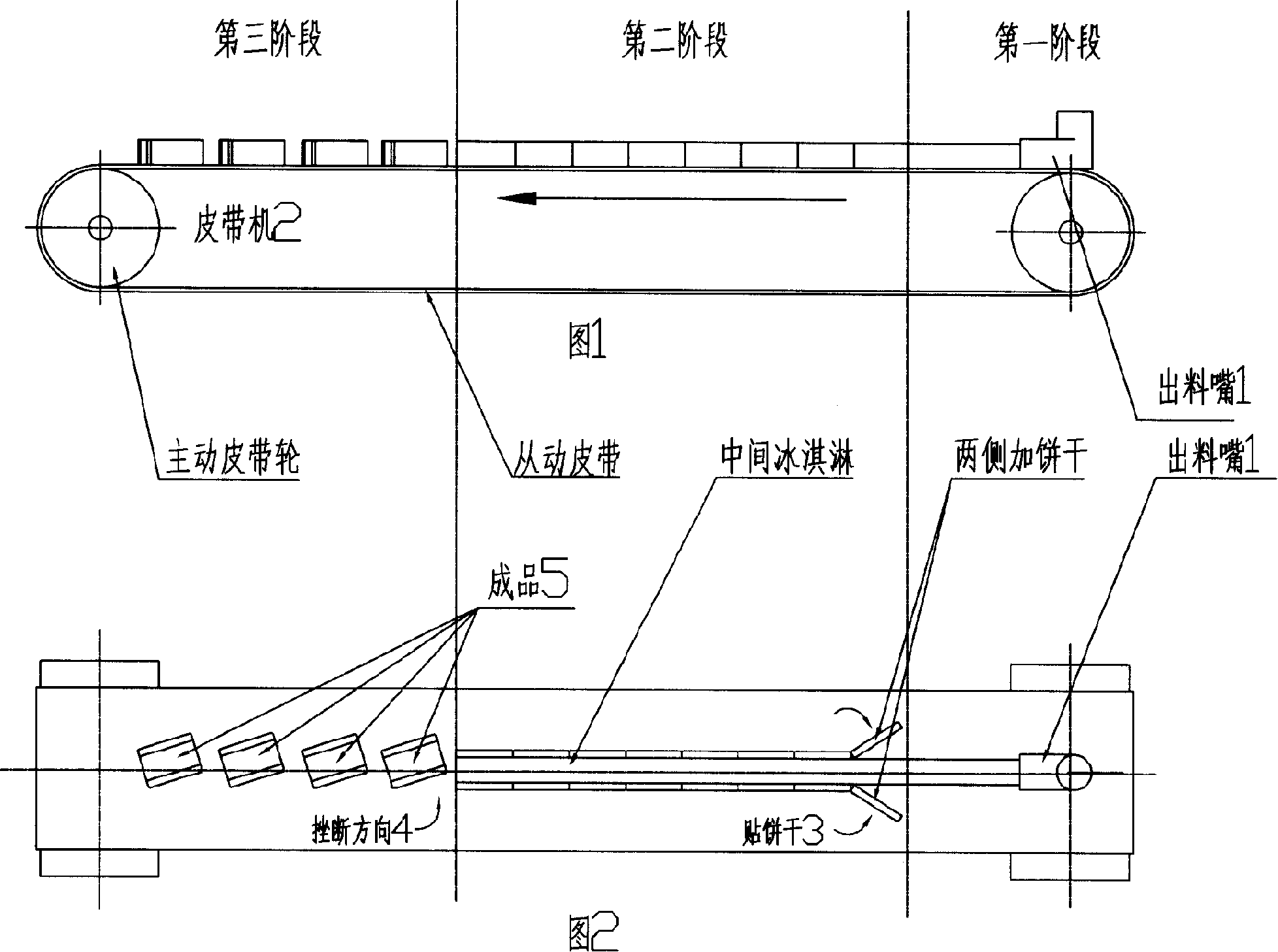

[0016] Embodiment 1: as shown in Fig. 1, Fig. 2, Fig. 3, the preparation technology of sandwich ice cream comprises three stages:

[0017] Wherein the first stage: through the square discharge nozzle 1, the ice cream material after freezing is extruded horizontally, and stretched on the belt conveyor 2 rotating at a uniform speed, wherein the discharge speed of the ice cream material is the same as the rotating speed of the belt conveyor unanimous.

[0018] The second stage: Biscuits 3 are pasted symmetrically and continuously on both sides of the shaped ice cream material advancing at a constant speed, and the biscuits are pasted one by one to form a line.

[0019] The third stage: from the head, the symmetrical biscuits are formed into a finished product 5 from the breaking direction 4 that is horizontal and vertical to the moving direction of the belt conveyor 2, and finally the finished product 5 is put into the tunnel freezing package.

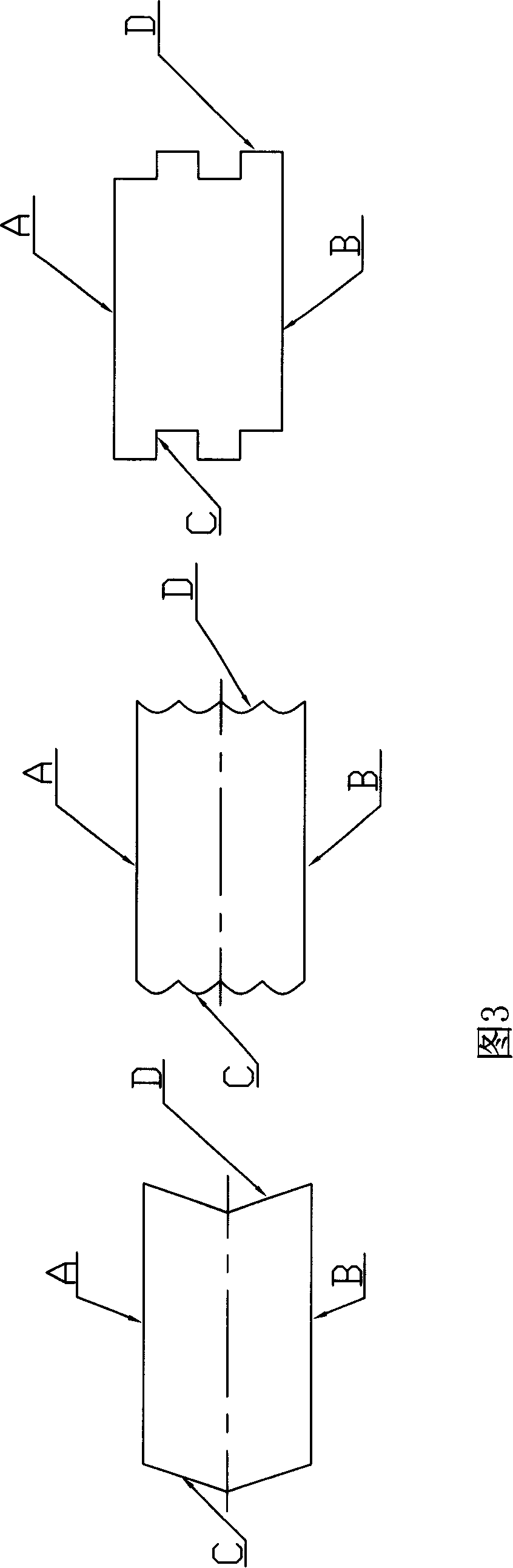

[0020] The bottom surface with bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com