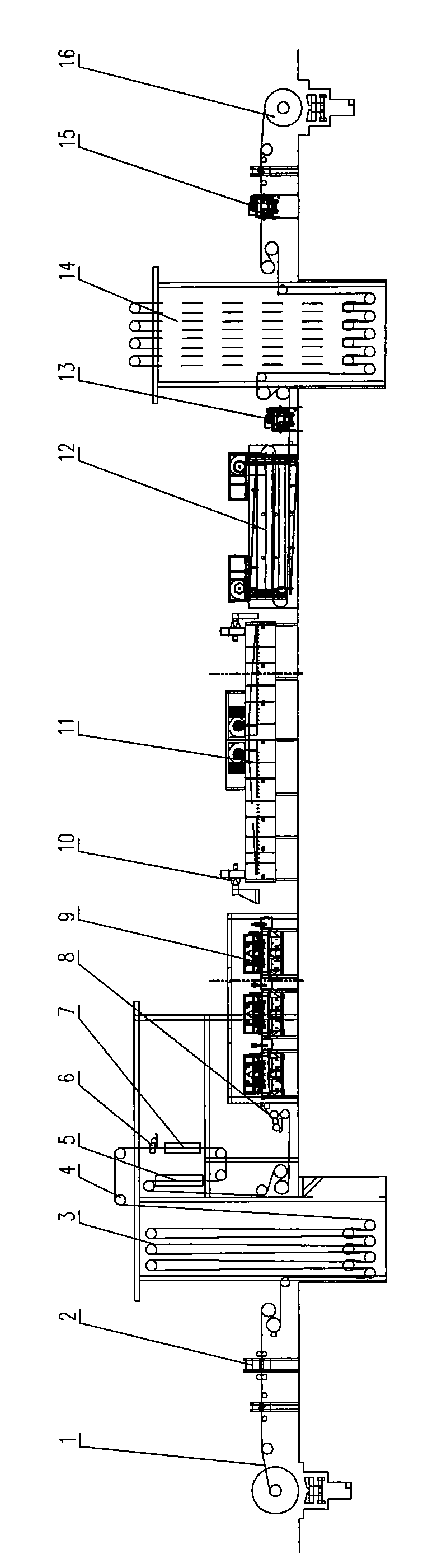

Continuous production process and production equipment for flocking steel belts and steel plates

A production process and production equipment technology, applied in the field of production equipment, can solve the problems of difficult to guarantee product quality and low production efficiency, and achieve the effects of high production efficiency, reliable product quality, and mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The continuous production technique of flocking steel strip of the present invention and steel plate, comprises the following steps:

[0030] a.

[0031] Open and flatten the coil of steel strip or steel plate;

[0032] b. Front storage and deviation correction

[0033] The uncoiled steel strip or steel plate enters the front storage device for storage, and then enters the deviation correction device for deviation correction;

[0034] c. Material pretreatment

[0035] Passivate the surface of the steel strip or steel plate, then dry and cool it;

[0036] d. Glue

[0037] Apply a layer of flocking glue on the surface of the steel strip or steel plate;

[0038] e. Flocking

[0039] The steel belt or steel plate after gluing is moved to the flocking station for flocking;

[0040] f. Drying, cooling and brushing

[0041] Dry and cool the flocked steel strip or steel plate, and then brush off the unadhered fluff on the steel strip or steel plate surface;

[0042] g....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com