Reciprocating multi-coated foam material production line

A foaming material and production line technology, applied in the field of industrial manufacturing, can solve the problems that no foaming material production line has been found and cannot be completely used in the field of foaming material production, and achieve the effects of saving raw materials, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

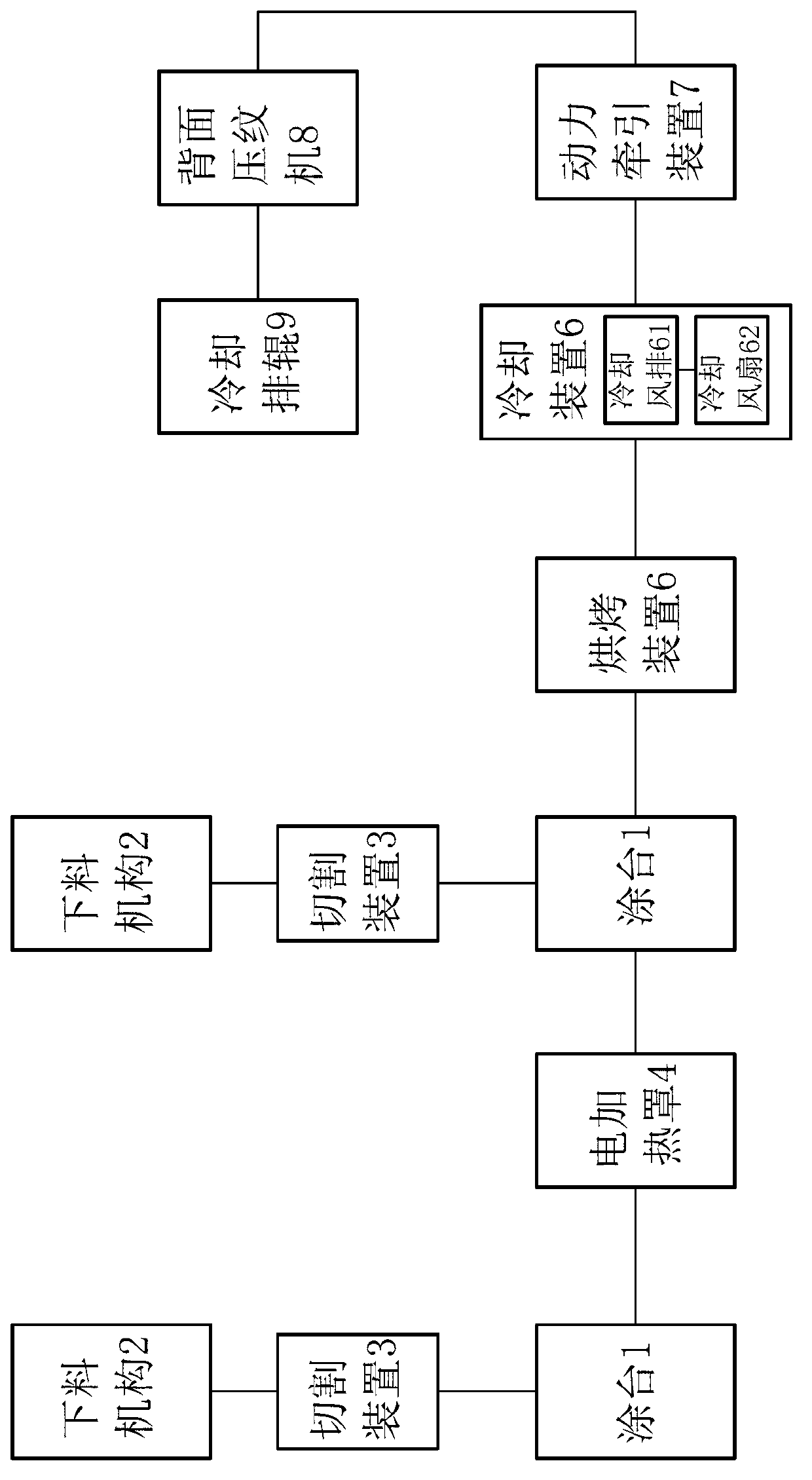

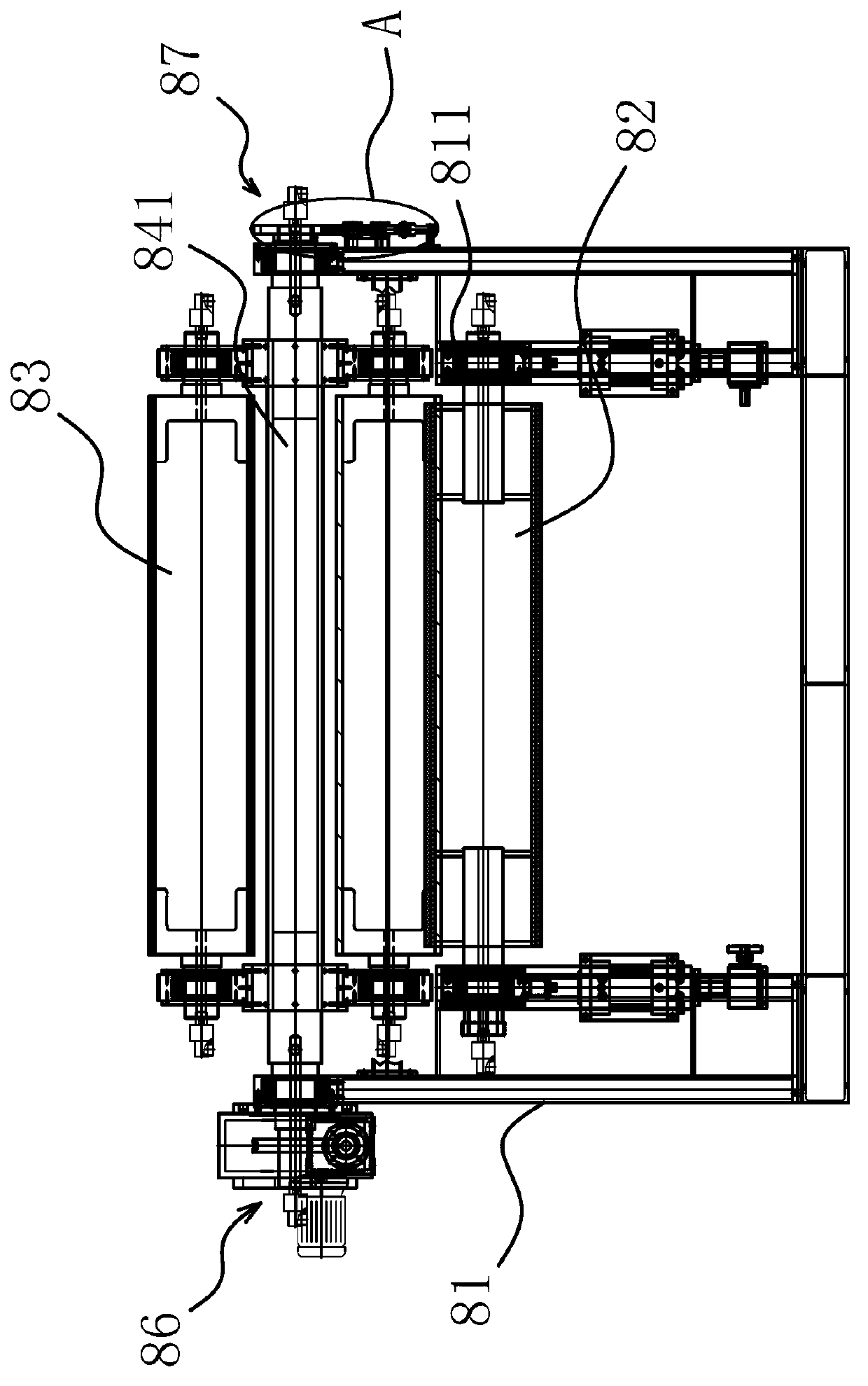

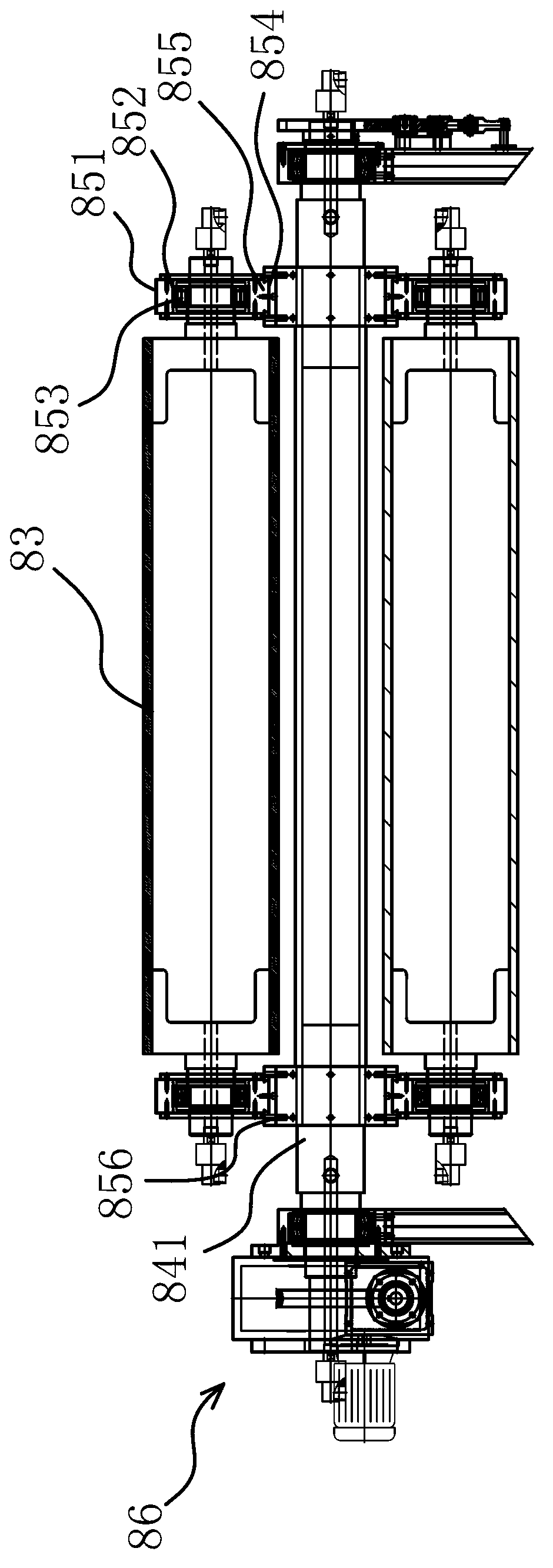

[0024] Such as figure 1 As shown, this reciprocating multi-coating foaming material production line includes a number of coating platforms 1 that are connected to each other and can support conveyor belts. Each coating platform 1 is provided with a blanking mechanism 2, and each blanking mechanism 2 and A cutting device 3 is provided at the contact point of the conveyor belt, and the unloading mechanism 2 can drive the cutting device 3 to reciprocate up and down, and an electric heating cover 4 capable of heating the conveyor belt is provided in the middle of every two coating stations 1. The other end of 1 is sequentially connected with a baking device 5, a cooling device 6 and a power traction device 7. The above-mentioned conveyor belt is connected with the back embossing machine 8 and the cooling roller 9 in sequence after passing through the power traction device 7. The cutting device 3 includes a belt There is a cutting knife with double-sided blades and the cutting knif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com