Pad dyeing technology of super-imitated cotton/cotton blended fabric

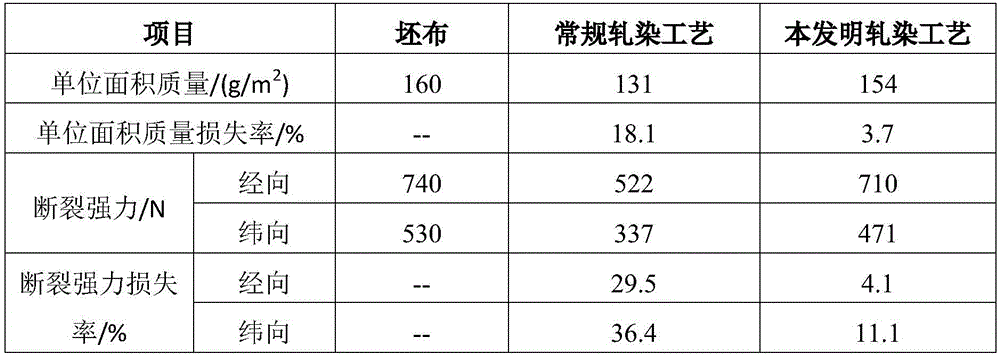

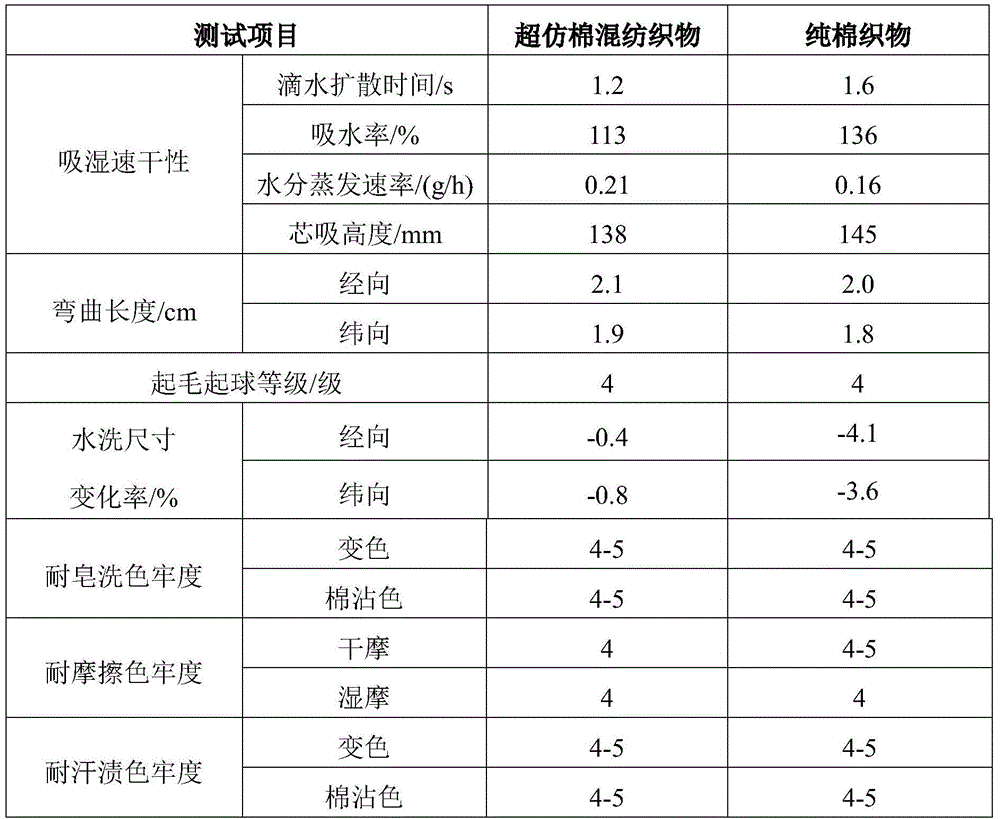

A technology of cotton blending and super imitation cotton, which is applied in heating/cooling fabric, dyeing method, liquid/gas/steam textile material treatment, etc. It can solve the problems of low efficiency and achieve low energy consumption, quality per unit area and breaking strength The effect of small loss and low alkali consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The selected fabric is super imitation cotton / cotton 60 / 40, 18.4tex / 18.4tex472 / 362 (root / 10cm) 2 / 1 twill 160cm

[0052] Step 1, deboil:

[0053] The super-imitation cotton / cotton blended fabric gray fabric is subjected to light alkali decooking treatment, and the decooking liquid is composed of the following raw materials: caustic soda 6g / L, high-efficiency refining agent OS-6035g / L, penetrating agent JFC 2g / L. The decoiling process is as follows: firstly, the super-imitation cotton / cotton blended fabric is dipped in the decoiling solution, using two dipping and two rolling, and the excess rate is 80% to 100%; then the super-imitation cotton / cotton after padding The blended fabric is steamed at a steaming temperature of 100°C to 102°C for 40 minutes; finally, the super imitation cotton / cotton blended fabric is washed with hot water and cold water;

[0054] Step 2, mercerizing:

[0055] Carry out low-alkali mercerizing to the fabric after deboiling in step 1, the caust...

Embodiment 2

[0066] The selected fabric is super imitation cotton / cotton 60 / 40, 18.4tex×2 / 18.4tex×2354 / 220 (root / 10cm) 2 / 1 twill 160cm

[0067] Step 1, deboil:

[0068] The super imitation cotton / cotton blended fabric gray fabric is subjected to light alkali decooking treatment, and the decooking liquid is composed of the following raw materials: caustic soda 4g / L, high-efficiency refining agent OS-6038g / L, penetrating agent JFC 2.5g / L. The decoiling process is as follows: firstly, the super-imitation cotton / cotton blended fabric is dipped in the decoiling solution, using two dipping and two rolling, and the excess rate is 80% to 100%; then the super-imitation cotton / cotton after padding The blended fabric is steamed, the steaming temperature is 100°C-102°C, and the time is 50min; finally, the super imitation cotton / cotton blended fabric is washed with hot water and cold water;

[0069] Step 2, mercerizing:

[0070] Carry out low-alkali mercerizing to the fabric after deboiling in step 1...

Embodiment 3

[0081] The selected fabric is super imitation cotton / cotton 40 / 60, 28.0tex / 28.0tex472 / 236 (root / 10cm) 3 / 1 twill 160cm

[0082] Step 1, deboil:

[0083] The super-imitation cotton / cotton blended fabric gray cloth is subjected to light alkali decooking treatment. The decooking solution is composed of the following raw materials: caustic soda 3g / L, high-efficiency refining agent OS-60310g / L, penetrating agent JFC 3g / L. The decoiling process is as follows: firstly, the super-imitation cotton / cotton blended fabric is dipped in the decoiling solution, using two dipping and two rolling, and the excess rate is 80% to 100%; then the super-imitation cotton / cotton after padding The blended fabric is steamed, the steaming temperature is 100°C-102°C, and the time is 60 minutes; finally, the super imitation cotton / cotton blended fabric is washed with hot water and cold water;

[0084] Step 2, mercerizing:

[0085] Carry out low-alkali mercerizing to the fabric after deboiling in step 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com