High-tin tinned plate edge quality control method

A technology of tin plate and tin amount, applied in the direction of plating tank, cell, electrolysis process, etc., can solve the problems of poor quality of strip edge, unable to guarantee continuous production of strip, damage of pressing roller, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

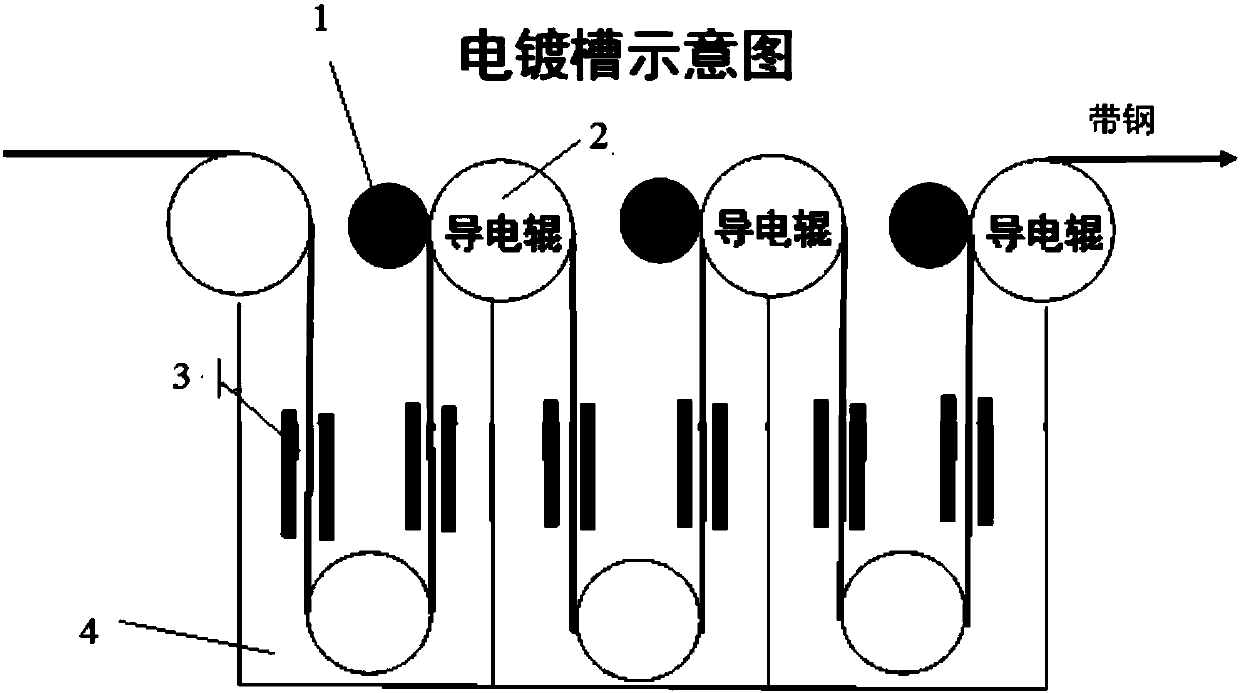

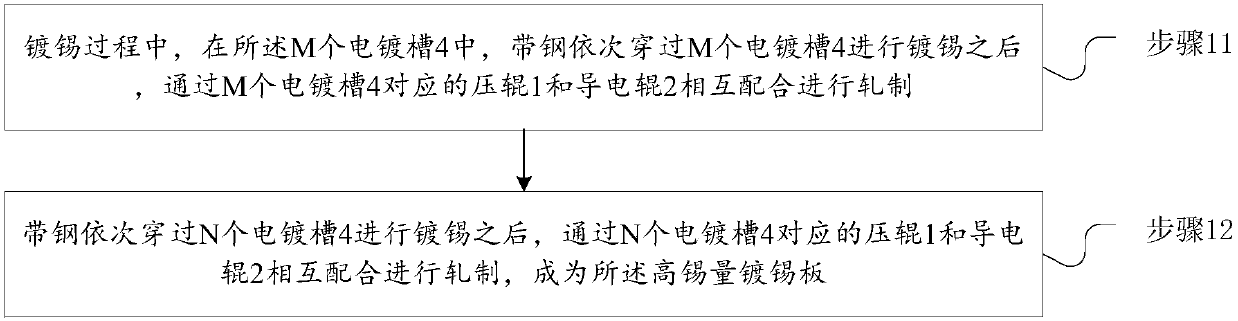

[0025] The invention discloses a method for controlling the edge quality of a high-tin tin plate, which is especially suitable for the tin plate with a tin content of 11.2g / m 2 In the production of high tin content tinplate, it is especially suitable for the vertical tank soluble anodic tin plating production line of all methanesulfonic acid plating solution systems. The invention relates to an electro-tin plating process and material selection of a conductive voltage roller. The main means are to improve the concentration of tin ions in the components of the electroplating solution; to optimize the current density of each pass in the electroplating tank; to change the material of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com