Method for preparing gold colloidal nanaparticles

A nano-gold and particle technology is applied in the field of preparation of gold nanoparticles, which can solve the problems of uneven distribution, unfavorable production and preparation, and difficult particle size control, and achieves the effect of easy particle size and continuous large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

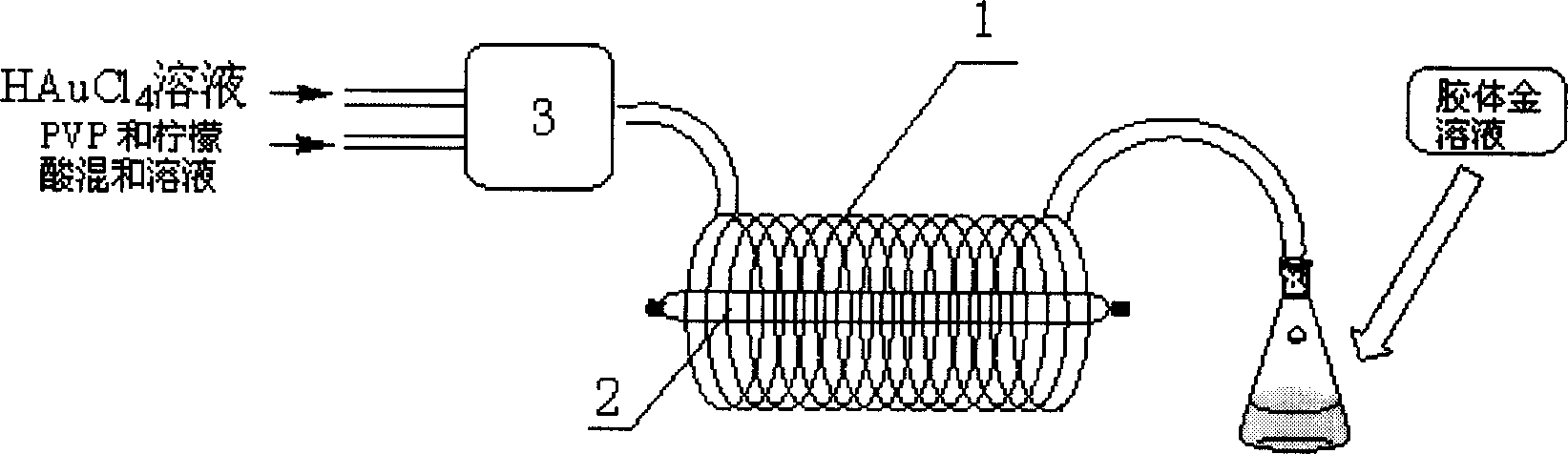

[0010] Embodiment 1, referring to accompanying drawing, at first, prepare the mixed solution of K15 and citric acid, make the concentration of K15 in the solution be 5mg / mL, citric acid concentration be 1mg / mL; Then, the chloroauric acid that concentration is 80 μ g / mL The aqueous solution of K15 and the mixed solution of K15 and citric acid are injected simultaneously at the flow rate of 6mL / min by dual-channel constant-flow pump 3 respectively. Under the irradiation wavelength of 253.7nm and the power of 14W ultraviolet lamp 2, the pipe diameter is 1mm and the screw pitch is 1mm. A quartz serpentine tube 1 with a tube length of 30 cm can obtain colloidal gold nanoparticles with an average particle diameter of 1.5 nm.

Embodiment 2

[0011] Embodiment 2, at first, prepare the mixed solution of K25 and citric acid, make the concentration of K25 in the solution be 2.5mg / mL, the concentration of citric acid is 0.8mg / mL; The mixed solution of K25 and citric acid was injected simultaneously with the flow rate of 30mL / min by dual-channel constant-flow pump 3 respectively. The tube diameter under the irradiation wavelength of 253.7nm and the power of 200W ultraviolet lamp 2 was 10mm, and the thread pitch was 5mm. The quartz serpentine tube 1 with a length of 100 cm can obtain colloidal gold nanoparticles with an average particle diameter of 2 nm.

Embodiment 3

[0012] Embodiment 3, at first, prepare the mixed solution of K30 and citric acid, make the concentration of K30 in the solution be 10mg / mL, citric acid concentration be 6.4mg / mL; Then, be the aqueous solution of the chloroauric acid of 800 μ g / mL and The mixed solution of K30 and citric acid is injected simultaneously with the flow rate of 60mL / min by dual-channel constant flow pump 3 respectively. The tube diameter under the radiation wavelength of 300nm and the power of 500W ultraviolet lamp 2 is 5mm, the thread pitch is 20mm, and the tube length is A 200 cm quartz serpentine tube 1 can obtain colloidal gold nanoparticles with an average particle diameter of 5 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com