Modacrylic, chinlon and combed cotton blended flame-retardant yarn

A technology of acrylic chloride fiber and combed cotton, which is applied in the field of flame retardant products and production technology, and can solve the problems of insignificant flame retardant effect, low wearing comfort, and high static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0025] Ingredients: 60% by weight of high flame-retardant acrylic chloride fiber, 35% by weight of first-grade combed long-staple cotton, and 5% by weight of nylon.

[0026] Preparation:

[0027] (1) Oil spraying treatment before putting into production: before putting into production, carry out oil spraying treatment on the acrylic chloride fiber, and the oil is TJCG-13 high-efficiency flame-retardant blended oil. The dosage ratio is oil agent: water = 1:700. Processing time ≥ 24 hours.

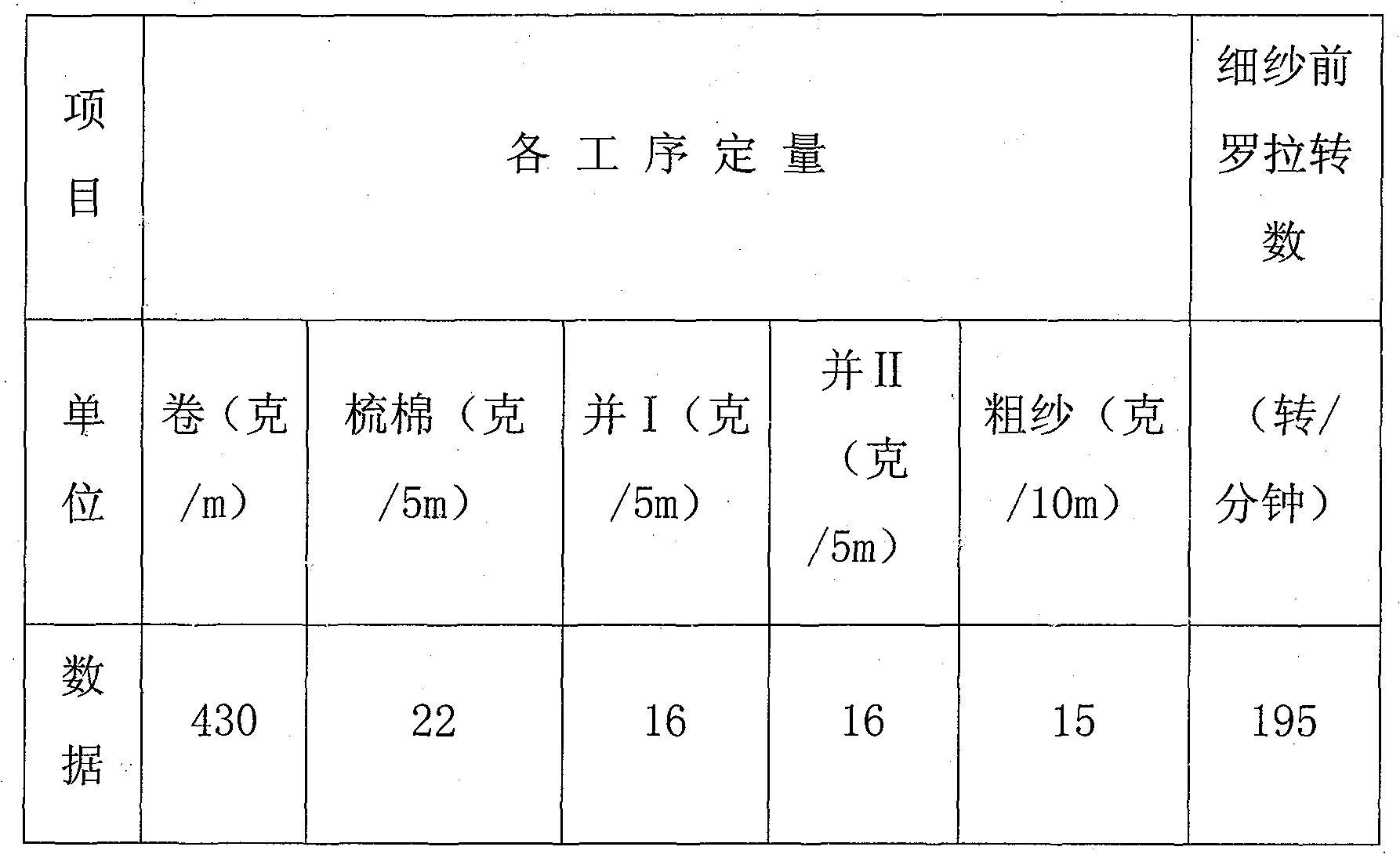

[0028] (2) Cotton cleaning process: the negative pressure of the pipeline in the whole process is good, and the pipeline is smooth. The lap weight is 430g / 5m.

[0029] (3) Carding process: Due to the high static electricity of textile fibers, the transfer is difficult. Therefore, a tight-gauge, fast-transfer process route is adopted. The weight is slightly heavier, 22.0g / 5m, and it is equipped with a noodle maker.

[0030] (4) Drawing process: This process is the breakthrough point of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com