Comfortable electric-arc-preventing flame retarding blends

A blend and anti-arc technology, which is applied in the manufacture of fire-resistant and flame-retardant filaments, single-component synthetic polymer rayon, and artificial filaments made of viscose, etc., can solve the problem of high finished product prices and flame-retardant rayon. The fiber is expensive and other problems, and achieves the effects of low heat loss, improved compactness, and delayed loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

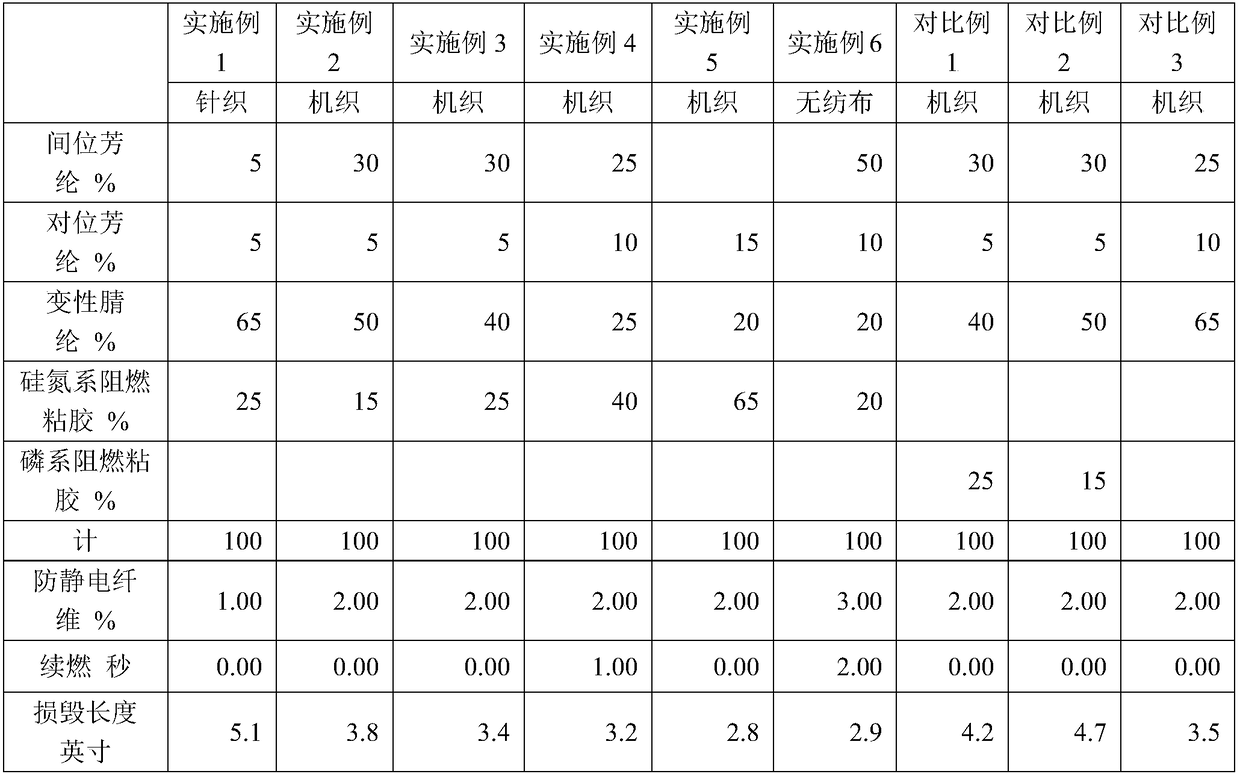

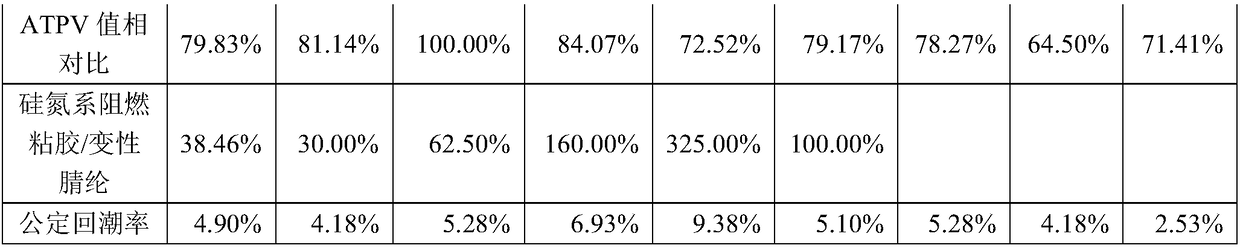

[0023] A comfortable arc-proof and flame-retardant blend, which is composed of meta-aramid, para-aramid, modified acrylic fiber, silicon nitrogen flame-retardant viscose and anti-static fiber; meta-aramid, para-aramid, denatured The sum of the mass of acrylic fiber and silicon-nitrogen flame-retardant viscose is recorded as A; the percentages of meta-aramid, para-aramid, modified acrylic fiber, and silicon-nitrogen flame-retardant viscose in A are: meta-aramid: 5 %; para-aramid: 5%; modacrylic: 65%; silicon nitrogen flame retardant viscose: 25%. The percentage of antistatic fiber in A is 1%.

Embodiment 2

[0025] A comfortable arc-proof and flame-retardant blend, which is composed of meta-aramid, para-aramid, modified acrylic fiber, silicon nitrogen flame-retardant viscose and anti-static fiber; meta-aramid, para-aramid, denatured The sum of the mass of acrylic fiber and silicon-nitrogen flame-retardant viscose is recorded as A; the percentages of meta-aramid, para-aramid, modified acrylic fiber, and silicon-nitrogen flame-retardant viscose in A are: meta-aramid: 30 %; Para-aramid fiber: 5%; Modacrylic fiber: 50%; Silicon nitrogen flame retardant viscose: 15%. The antistatic fiber accounts for 2% of A.

Embodiment 3

[0027] A comfortable arc-proof and flame-retardant blend, which is composed of meta-aramid, para-aramid, modified acrylic fiber, silicon nitrogen flame-retardant viscose and anti-static fiber; meta-aramid, para-aramid, denatured The sum of the mass of acrylic fiber and silicon-nitrogen flame-retardant viscose is recorded as A; the percentages of meta-aramid, para-aramid, modified acrylic fiber, and silicon-nitrogen flame-retardant viscose in A are: meta-aramid: 30 %; Para-aramid fiber: 5%; Modacrylic fiber: 40%; Silicon nitrogen flame retardant viscose: 25%. The antistatic fiber accounts for 2% of A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com