Arc protective fabric with single-layer three-dimensional structure and preparation method of arc protective fabric

A three-dimensional structure and anti-arc technology, which is applied in the direction of fabric surface trimming, weaving, yarn, etc., to improve the overall thermal insulation performance, improve skin-adherence and wearing comfort, and enhance the effect of functional protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

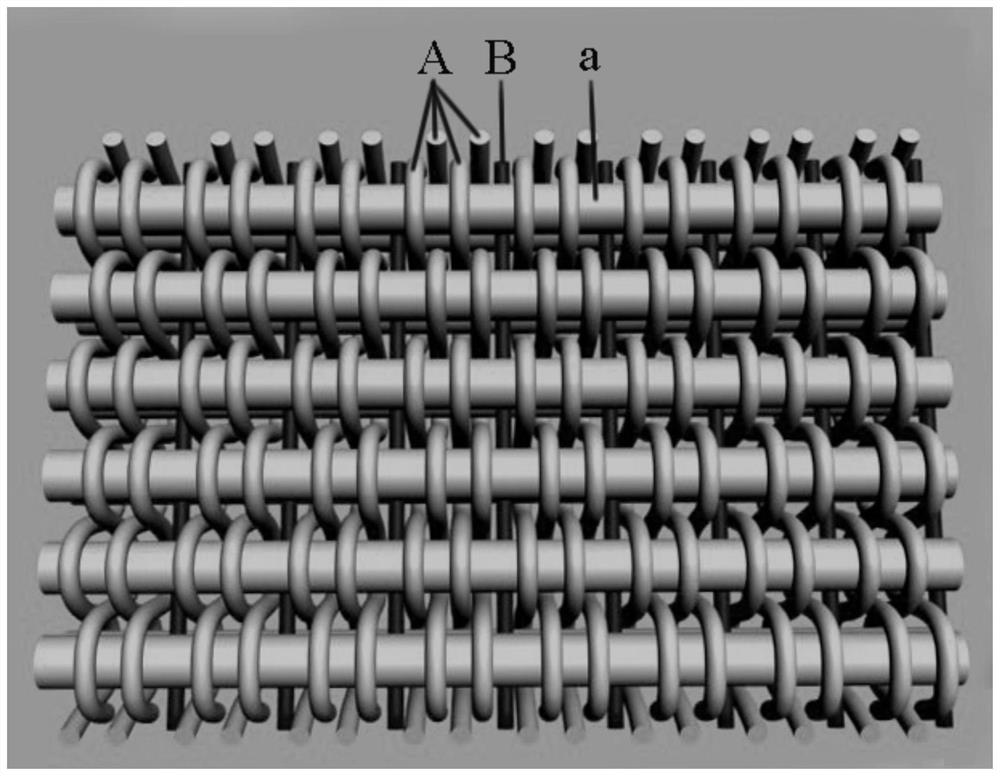

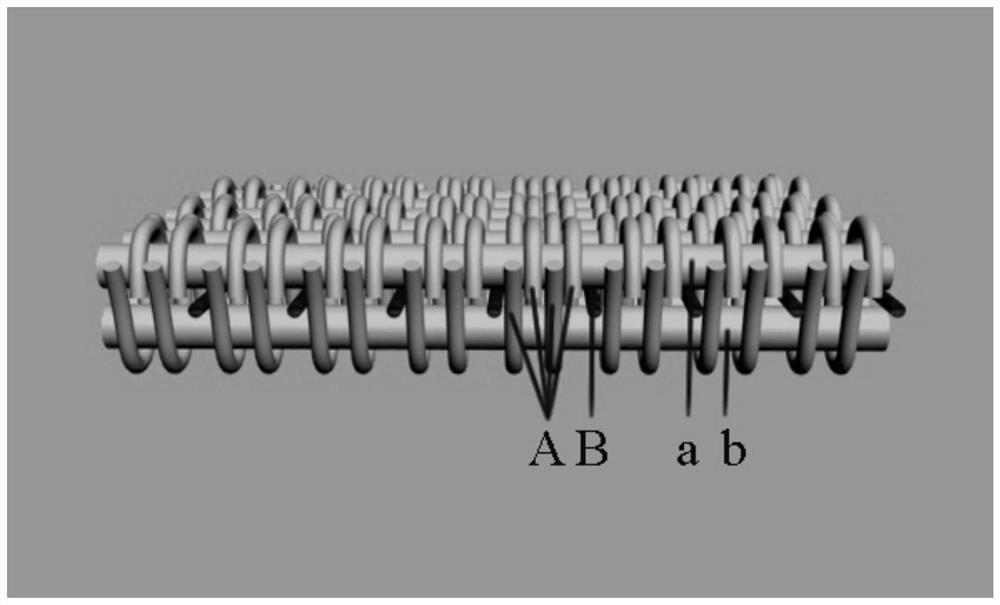

[0030] A single-layer three-dimensional arc-proof fabric of the present invention is formed by interweaving warp yarns and weft yarns. There are two types of warp yarns and two types of weft yarns.

[0031] Two further warp yarns, one for the main body yarn and one for the middle layer yarn. The main warp yarn is a blended yarn, and the yarn contains 50% flame-retardant viscose fiber, 30% aramid 1313 fiber, 10% acrylic fiber, and 10% nylon fiber; the middle layer warp yarn is 100% polyimide filament.

[0032] Further two kinds of weft yarns, one is the upper layer weft yarn, and the other is the lower layer weft yarn. The upper weft yarn is a blended yarn, the yarn contains 50% flame-retardant viscose fiber, 20% aramid 1313 fiber, 10% aramid 1414, 10% acrylic fiber, 5% nylon fiber; the lower weft yarn is also a blended yarn, The yarn contains 70% flame retardant viscose fiber, 25% aramid 1313 fiber, 5% aramid 1414 fiber.

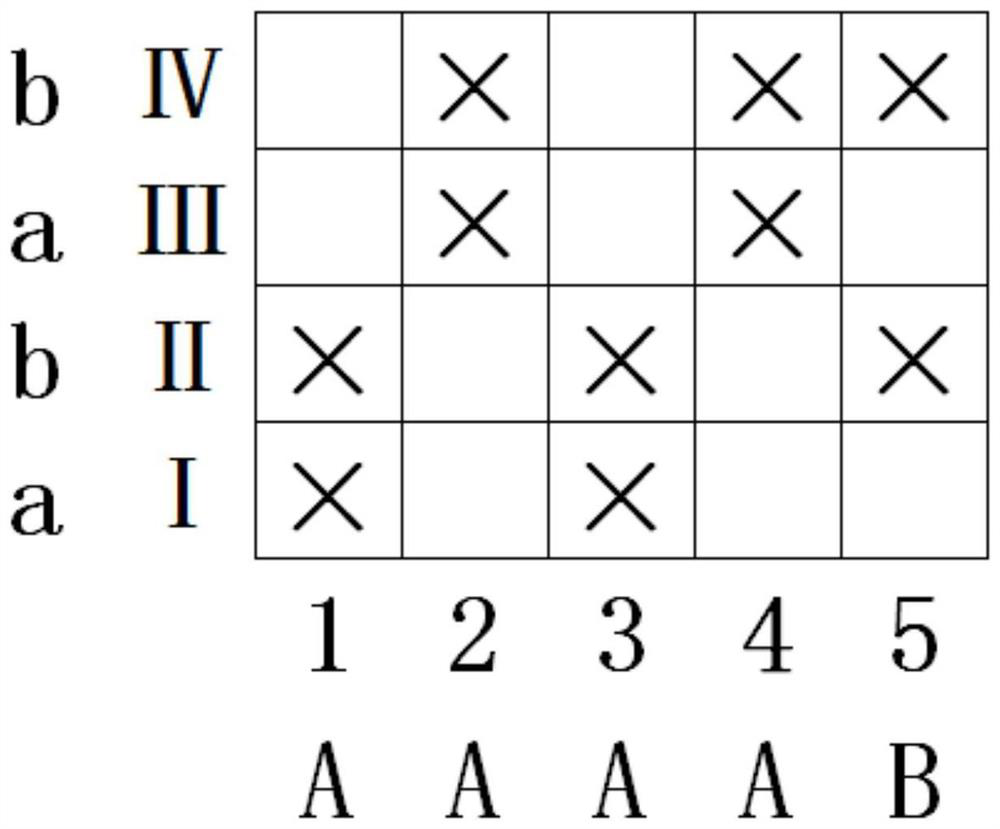

[0033] Further, the weave structure of the fabric is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com