A high-efficiency arc protection fabric and its preparation method

An arc protection and fabric technology, applied in dyeing, textile, textile and papermaking, etc., can solve the problems of insufficient anti-explosion performance, insufficient comfort, and general arc protection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a preparation method of high-efficiency arc protection fabric, comprising the following steps:

[0041] The present invention also provides a preparation method of high-efficiency arc protection fabric, comprising the following steps:

[0042] Step 1) raw material selection: select the following components according to the mass percentage: 30%~75% acrylic fiber, 10%~20% meta-aramid fiber, 10~35% high temperature dimensionally stable fiber, 5%~10 % polyamide fiber and 0-5% conductive fiber;

[0043] Step 2) Spinning: using step (1) as the raw material, proceed through raw material pretreatment→carding→drawing→roving→spinning→winding→doubling→twisting to make a blended finished yarn;

[0044] Step 3) warping;

[0045] Step 4) sizing: applying sizing on the warp yarns,

[0046] The slurry includes 85.5% to 92.5% of starch, 3.5% to 5.5% of modifier, 2% to 4.5% of smoothing agent, and 2% to 4.5% of antistatic agent in terms of mass rati...

Embodiment 1

[0057] A kind of embodiment provided by the present invention: the technical solution adopted in the present invention is, a kind of novel arc protection fabric, warp and weft yarns are 35% acrylic fiber, 20% meta-aramid fiber, 20% para-aramid fiber fiber, 15% polyimide fiber, 5% polyamide fiber, 5% conductive fiber blended fiber, the sum of the six fiber mass percentages is 100%.

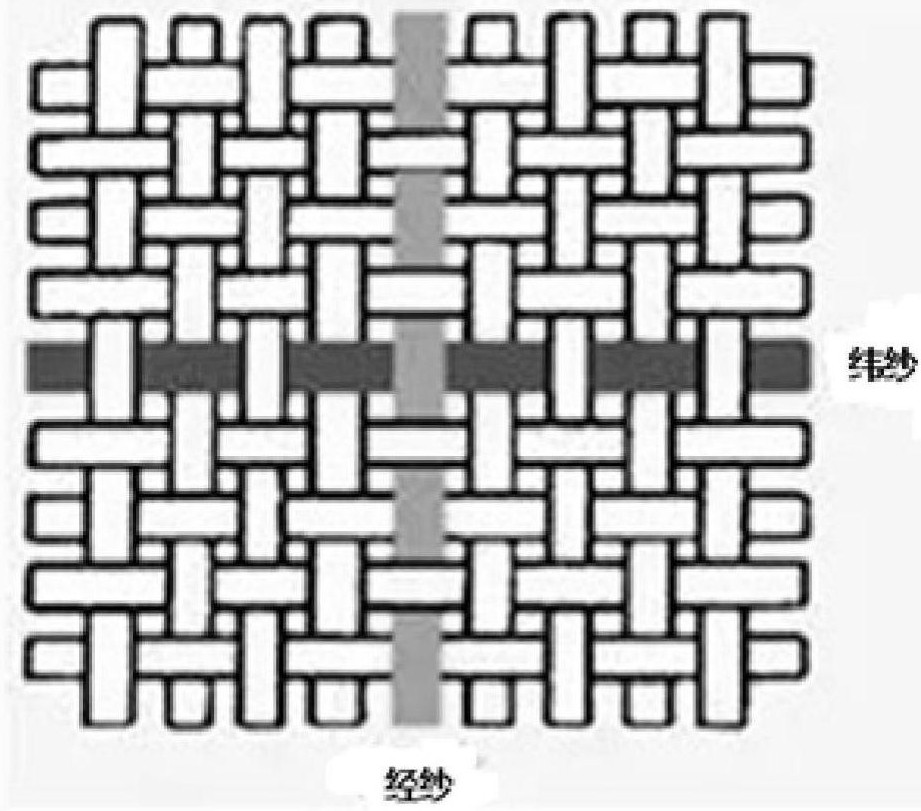

[0058] The linear density of the blended yarn was 24.6 tex x 2. The fabric structure is 3 / 1 twill weave, and the mass per unit area of the gray fabric is 250g / m 2 .

[0059] The above-mentioned new high-efficiency arc protection fabric adopts the following weaving process, and the steps are as follows:

[0060] (1) Raw material selection: select the following components according to mass percentage: 35% acrylic fiber, 20% meta-aramid fiber, 20% para-aramid fiber, 15% polyimide fiber, 5% poly Amide fiber, 5% conductive fiber.

[0061] (2) Spinning: through raw material pretreatment→carding→dra...

Embodiment 2

[0075] A kind of embodiment provided by the present invention: the technical scheme adopted in the present invention is, a kind of novel arc protection fabric, warp and weft yarns are 30% acrylic fiber, 20% meta-aramid fiber, 35% para-aramid fiber fiber, 10% polyamide fiber, 5% conductive fiber blended fiber, the sum of the five fiber mass percentages is 100%.

[0076] The linear density of the blended yarn was 13.0 tex×2. The fabric structure is 1 / 1 plain weave, and the mass per unit area of gray cloth is 160g / m 2 .

[0077] The above-mentioned new high-efficiency arc protection fabric adopts the following weaving process, and the steps are as follows:

[0078] (1) Raw material selection: select the following components according to mass percentage: 30% acrylic fiber, 20% meta-aramid fiber, 35% para-aramid fiber, 10% polyamide fiber, 5% conductive fiber.

[0079] (2) Spinning: through raw material pretreatment → carding → drawing frame → roving → spun yarn → winding → pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com