Quick-drying flame-retardant arc protection core-spun yarn

An anti-arc and core-spun technology, which is applied in the direction of yarn, textile and paper making, can solve the problems of non-skin-friendly and air-tight, and achieve the effect of fast drying speed and low moisture regain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

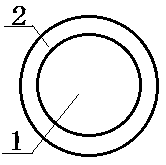

[0029] A quick-drying flame-retardant arc-proof core-spun yarn, the core-spun yarn includes a core layer 1 and a skin layer 2, the skin layer 2 is coated on the outside of the core layer 1; the core layer 1 is made of flame-retardant filaments fibers or flame-retardant and non-hygroscopic spun yarns, and the skin layer 2 is composed of flame-retardant polyimide fibers, flame-retardant viscose fibers, flame-retardant acrylic fibers, and wool fiber blends; the cross-sectional area of the core layer 1 occupies 10%-50% of the cross-sectional area of the core yarn; the skin layer 2 is evenly mixed with flame-retardant polyimide fiber, flame-retardant viscose fiber, flame-retardant acrylic fiber and wool fiber and coated on the core layer through the spinning process 1 obtained from outside; the mass ratio of flame-retardant viscose fiber in the skin layer 2 is: 10-50 parts; the mass ratio of flame-retardant acrylic fiber in the skin layer 2 is: 10-60 parts; The mass ratio of fl...

Embodiment 2

[0031] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0032] The cross-sectional area of the core layer 1 accounts for 10% of the cross-sectional area of the core-spun yarn.

[0033] The mass ratio of the flame-retardant viscose fiber in the cortex 2 is: 40 parts; the mass ratio of the flame-retardant acrylic fiber in the cortex 2 is: 25 parts; the mass ratio of the flame-retardant polyimide fiber in the cortex 2 The mass part ratio is: 30 parts; the mass part ratio of the wool fiber in the cortex 2 is: 5 parts.

[0034] The material of the core layer 1 can be composed of any one of polyimide staple fiber, flame-retardant polyester staple fiber, and flame-retardant polypropylene staple fiber.

Embodiment 3

[0036] Embodiment 3 is basically the same as Embodiment 1, and its difference is:

[0037] The cross-sectional area of the core layer 1 accounts for 20% of the cross-sectional area of the core-spun yarn.

[0038] The mass ratio of the flame-retardant viscose fiber in the cortex 2 is: 50 parts; the mass ratio of the flame-retardant acrylic fiber in the cortex 2 is: 10 parts; the mass ratio of the flame-retardant polyimide fiber in the cortex 2 The mass ratio is: 50 parts; the mass ratio of the wool fiber in the cortex 2 is: 1 part.

[0039] The material of the core layer 1 can be composed of any one of polyimide staple fiber, flame-retardant polyester staple fiber, and flame-retardant polypropylene staple fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com