Preparation method of composite macromolecular sizing agent

A sizing agent and polymer technology, applied in the field of papermaking, can solve the problems of AKD sizing agent being easily hydrolyzed and not resistant to storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] AKD: AKD emulsion, C16.

[0019] AKD addition ratio: 15%

[0020] SAE sizing agent preparation monomer is under nitrogen protection and stirring, add initiator, control the temperature at 120°C, and react for 1h; cool to 80°C, add initiator, defoamer, and add 15% AKD emulsion (C16) , PH control 5, heat preservation reaction 1h, add initiator, slowly drop secondary synthesis monomer, control dosing time 2h, heat preservation and continuous reaction 1h, cool down to 30°C to prepare composite polymer sizing agent.

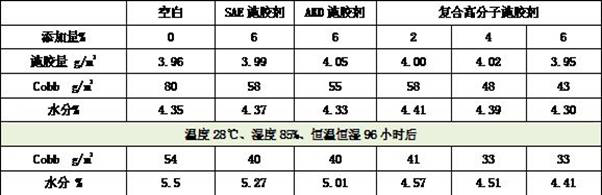

[0021] Dilute tapioca raw starch to a concentration of 10% after enzymatic digestion and cooking, add compound polymer sizing agent, SAE sizing agent, and C16 AKD emulsion sizing agent to prepare glue solution; use NBKP:LBKP:BCTMP=20:70 :10 ratio paper-making as base paper for sizing evaluation.

[0022] Composite polymer sizing agent stability: no delamination, hydrolysis and agglomeration when stored at room temperature for 3 months.

[0023]

[0024] T...

Embodiment 2

[0026] AKD: AKD emulsion, C14.

[0027] AKD addition ratio: 35%

[0028] SAE sizing agent preparation monomers are under nitrogen protection and stirring, add initiators, control the temperature at 120°C, and react for 1h; cool to 85°C, add initiators and defoamers, slowly drop secondary synthesis monomers, add The drug time is controlled for 1 hour, the heat preservation is continued for 0.5 hours, the temperature is lowered to 60°C, the initiator, 35% AKD emulsion (C14) is added, the pH is controlled to 4, the heat preservation reaction is 1.5h, and the temperature is cooled to 30°C to obtain a composite high molecular sizing agent.

[0029] Dilute corn starch to a concentration of 10% after enzymatic digestion and cooking, add compound polymer sizing agent, SAE sizing agent, and C14 AKD emulsion sizing agent to prepare glue; use 100% OCC pulp papermaking as the base paper , for sizing evaluation.

[0030] Composite polymer sizing agent stability: no delamination, hydroly...

Embodiment 3

[0034] AKD: AKD wax, C18.

[0035] AKD addition ratio: 25%

[0036] SAE sizing agent preparation monomers are under nitrogen protection and stirring, add initiators, control the temperature at 120°C, and react for 1h; cool to 85°C, add initiators and defoamers, slowly drop secondary synthesis monomers, add The drug time is controlled for 2 hours, the heat preservation is continued for 1 hour, the temperature is lowered to 40 °C, the initiator and 25% AKD wax (C18) are added, the pH is controlled to 3, the heat preservation reaction is 2 hours, and the temperature is cooled to 30 °C to obtain a composite polymer. Glue.

[0037] Dilute tapioca raw starch to 10% concentration after enzymatic digestion and cooking, add composite polymer sizing agent, SAE sizing agent, and C18 AKD wax emulsified emulsion to prepare glue; use 100% BCTMP pulp papermaking as the base paper , for sizing evaluation.

[0038] Composite polymer sizing agent stability: no delamination, hydrolysis and ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com