High-strength composite sewing thread and preparing method thereof

A sewing thread, high-strength technology, applied in the direction of melt spinning, conjugated synthetic polymer artificial filament, yarn, etc., can solve the problems of low tensile strength, melting, blocking needle holes, etc., and achieve wear resistance and high temperature resistance Excellent performance, reduce melt reflux degradation, and reduce moisture regain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

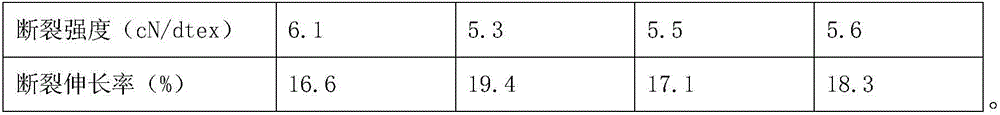

Embodiment 1

[0014] Example 1: A high-strength composite sewing thread, comprising the following raw materials in parts by weight: 40 parts of polypropylene resin, 1 part of polyethylene resin, 15 parts of poly-4-methyl-1-pentene, 0.05 parts of whitening agent, 3 parts of reinforcing fiber, 0.5 parts of auxiliary agent.

[0015] In this example, the whitening agent is whitening agent AD; the auxiliary agent is zinc stearate, which is used to improve the processability of the material during extrusion and spinning; the reinforcing fiber is silane The bamboo fiber pretreated by the coupling agent is used to improve the interfacial compatibility when it is compounded with the resin, and the fineness of the bamboo fiber is 100-800 mesh.

[0016] The preparation method of the high-strength composite sewing thread comprises the following steps: placing polypropylene resin, polyethylene resin, poly-4-methyl-1-pentene and reinforcing fibers in a banbury mixer for 15 minutes, banburying The temper...

Embodiment 2

[0017] Example 2: A high-strength composite sewing thread, comprising the following raw materials in parts by weight: 60 parts of polypropylene resin, 8 parts of polyethylene resin, 25 parts of poly-4-methyl-1-pentene, 0.10 parts of whitening agent, 8 parts of reinforcing fiber, 2 parts of auxiliary agent.

[0018] In the present embodiment, described whitening agent is whitening agent AD; Described auxiliary agent is calcium stearate; Described reinforcing fiber is the bamboo fiber of pretreatment through silane coupling agent, and the fineness of described bamboo fiber is 100-800 mesh.

[0019] The preparation method of the high-strength composite sewing thread comprises the following steps: placing polypropylene resin, polyethylene resin, poly-4-methyl-1-pentene and reinforcing fibers in a banbury mixer for 20 minutes, and banburying The smelted sample is pulverized and uniformly mixed with brighteners and auxiliary agents to obtain a premix; the premix is placed in a tw...

Embodiment 3

[0020] Embodiment 3: A high-strength composite sewing thread, comprising the following raw materials in parts by weight: 50 parts of polypropylene resin, 5 parts of polyethylene resin, 20 parts of poly-4-methyl-1-pentene, 0.06 parts of whitening agent, 5 parts of reinforcing fiber, 1 part of auxiliary agent.

[0021] In the present embodiment, described whitening agent is whitening agent AD; Described auxiliary agent is zinc stearate; Described reinforcing fiber is the bamboo fiber of pretreatment through silane coupling agent, and the fineness of described bamboo fiber is 100-800 mesh.

[0022] The preparation method of the high-strength composite sewing thread comprises the following steps: placing polypropylene resin, polyethylene resin, poly-4-methyl-1-pentene and reinforcing fibers in an internal mixer for internal mixing for 18 minutes, and mixing The smelted sample is pulverized and uniformly mixed with brighteners and auxiliary agents to obtain a premix; the premix is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com