Arc-proof flame-retardant glove and production method thereof

A production method and anti-arc technology, applied to gloves, protective clothing, clothing, etc., can solve the problems of heavy, inflexible, inconvenient to wear, etc., achieve good wear resistance, improve the interface state, and wear lightly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

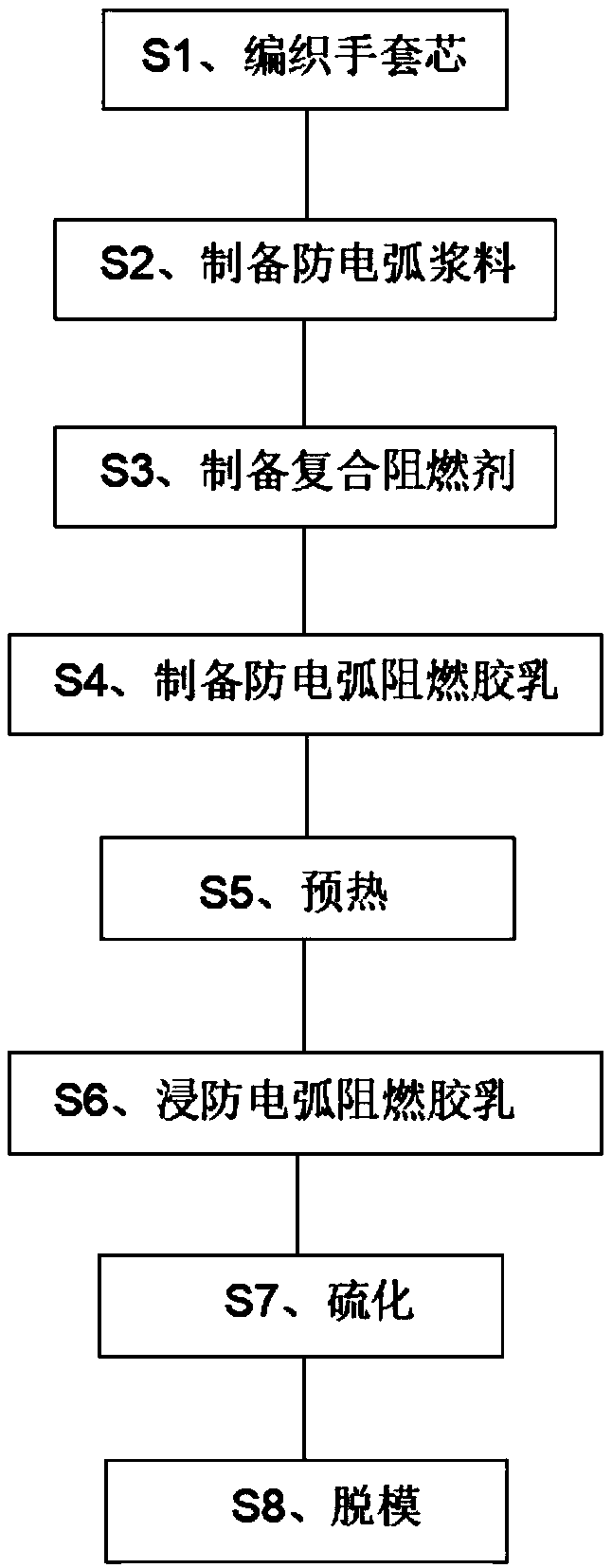

[0044] see figure 1 . Such as figure 1 As shown, the present embodiment discloses a method for producing arc-proof and flame-retardant gloves, comprising the following steps:

[0045] S1, braided glove core;

[0046] S2, preparation of arc-proof slurry:

[0047] Select the anti-arc powder and the anti-arc powder solvent, and mix the anti-arc powder and the anti-arc powder solvent to obtain the anti-arc slurry; wherein, the anti-arc powder is red phosphorus coated with microcapsules, and the microcapsules The particle size of the capsule-coated red phosphorus is 15 μm, the anti-arc solvent is methanol, the microcapsule-coated red phosphorus is 100 parts, and the methanol is 100 parts;

[0048] S3, prepare composite flame retardant:

[0049] Select zinc borate as a flame retardant synergist, mix and grind 50 parts by weight of polydiphosphazene, 50 parts of triethyl phosphate and 5 parts of zinc borate to obtain a composite flame retardant;

[0050] S4, preparation of arc-...

Embodiment 2

[0060] This embodiment discloses a method for producing arc-proof and flame-retardant gloves, which includes the following steps:

[0061] S1, braided glove core;

[0062] S2, preparation of arc-proof slurry:

[0063] Select the anti-arc powder and the anti-arc powder solvent, and mix the anti-arc powder and the anti-arc powder solvent to obtain the anti-arc slurry; wherein, the anti-arc powder is modified aluminum hydroxide, and the modified The particle size of aluminum hydroxide is 15 μm, the arc-proof solvent is water, the modified aluminum hydroxide is 100 parts, and the water is 100 parts;

[0064] S3, prepare composite flame retardant:

[0065] Select zinc borate as a flame retardant synergist, mix and grind 50 parts by weight of polydiphosphazene, 50 parts of triethyl phosphate and 5 parts of zinc borate to obtain a composite flame retardant;

[0066] S4, preparation of arc-proof and flame-retardant latex:

[0067] Select 50 parts of anti-arc slurry, 10 parts of co...

Embodiment 3

[0076] This embodiment discloses a method for producing arc-proof and flame-retardant gloves, which includes the following steps:

[0077] S1, braided glove core;

[0078] S2, preparation of arc-proof slurry:

[0079] Select the anti-arc powder and the anti-arc powder solvent, and mix the anti-arc powder and the anti-arc powder solvent to obtain the anti-arc slurry; wherein, the anti-arc powder is microcapsule-coated red phosphorus and modified hydrogen Alumina, the particle size of the microcapsule-coated red phosphorus is 15 μm, the particle size of the modified aluminum hydroxide is 15 μm, the arc-proof solvent is ethanol, and the microcapsule-coated red phosphorus is 100 parts, The modified aluminum hydroxide is 100 parts, and the ethanol is 200 parts;

[0080] S3, prepare composite flame retardant:

[0081] Zinc borate is selected as a flame retardant synergist, and 60 parts by weight of polydiphosphazene, 80 parts of triethyl phosphate and 8 parts of zinc borate are m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com