Low-frequency transformer with built-in shielding layer

A shielding layer and transformer technology, which is applied in the field of low-frequency transformers, can solve the problems of poor insulation performance and poor convenience of pin disassembly and assembly, and achieve the effects of improving shock resistance, improving heat dissipation performance, and increasing heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

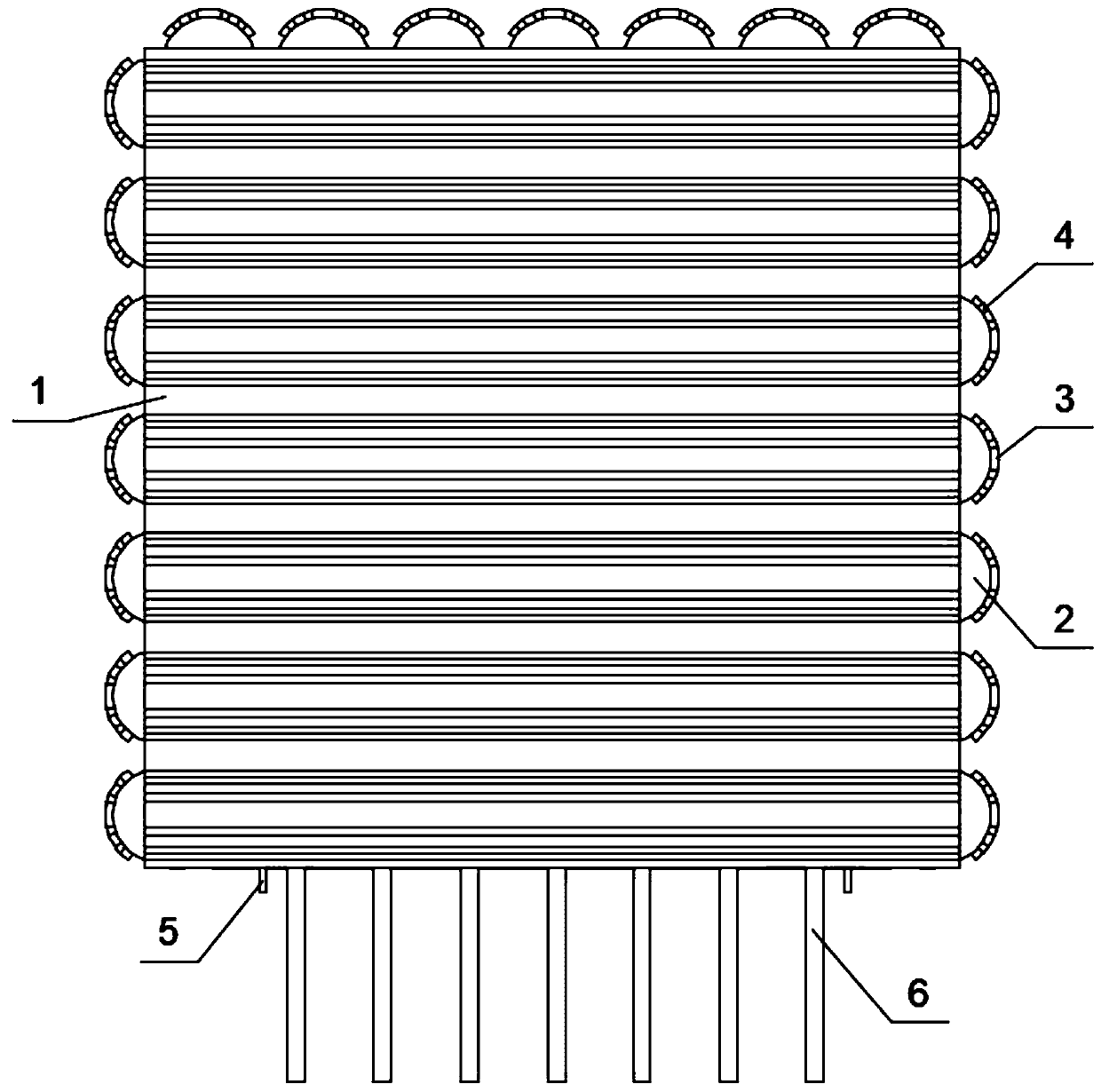

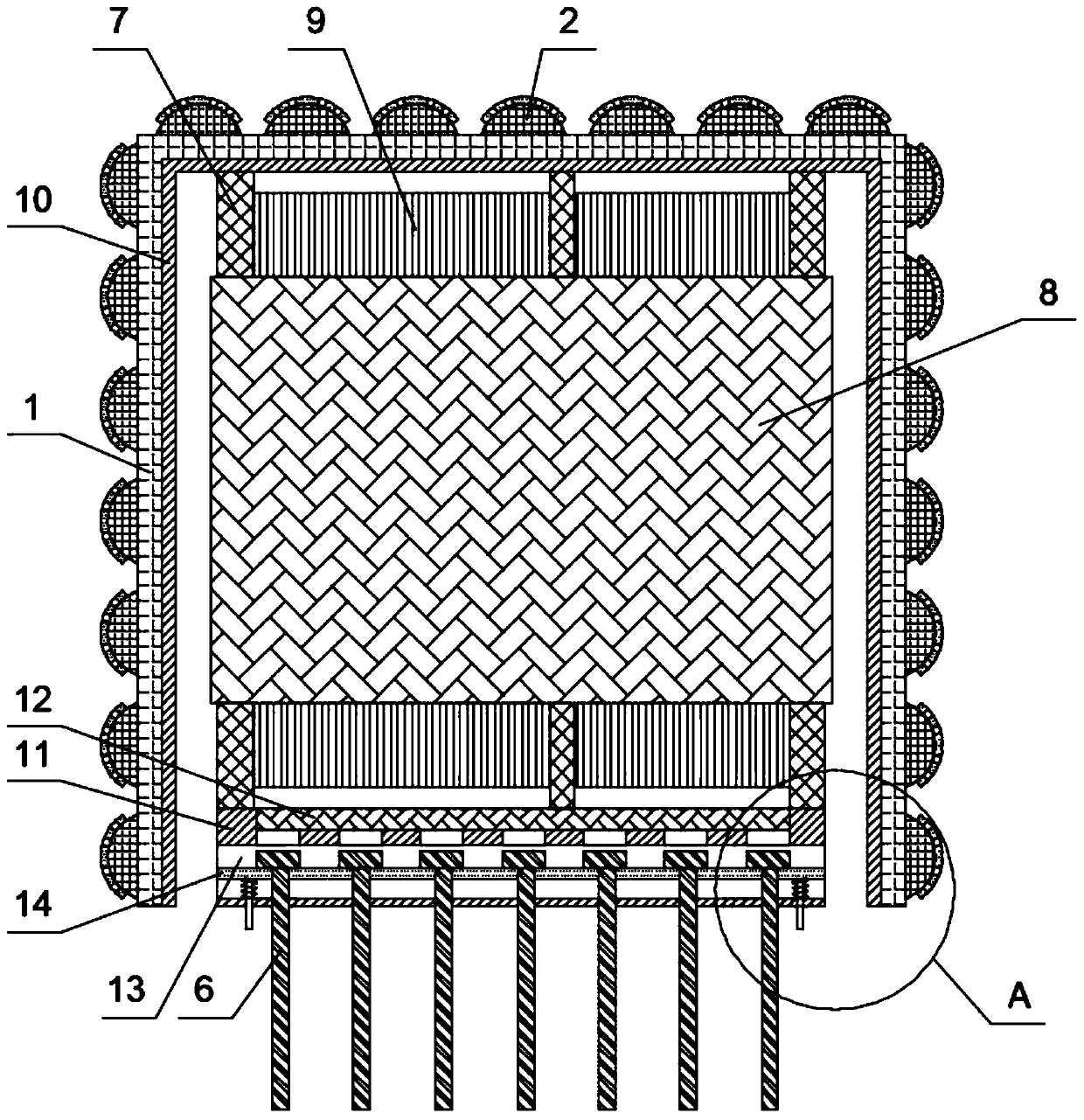

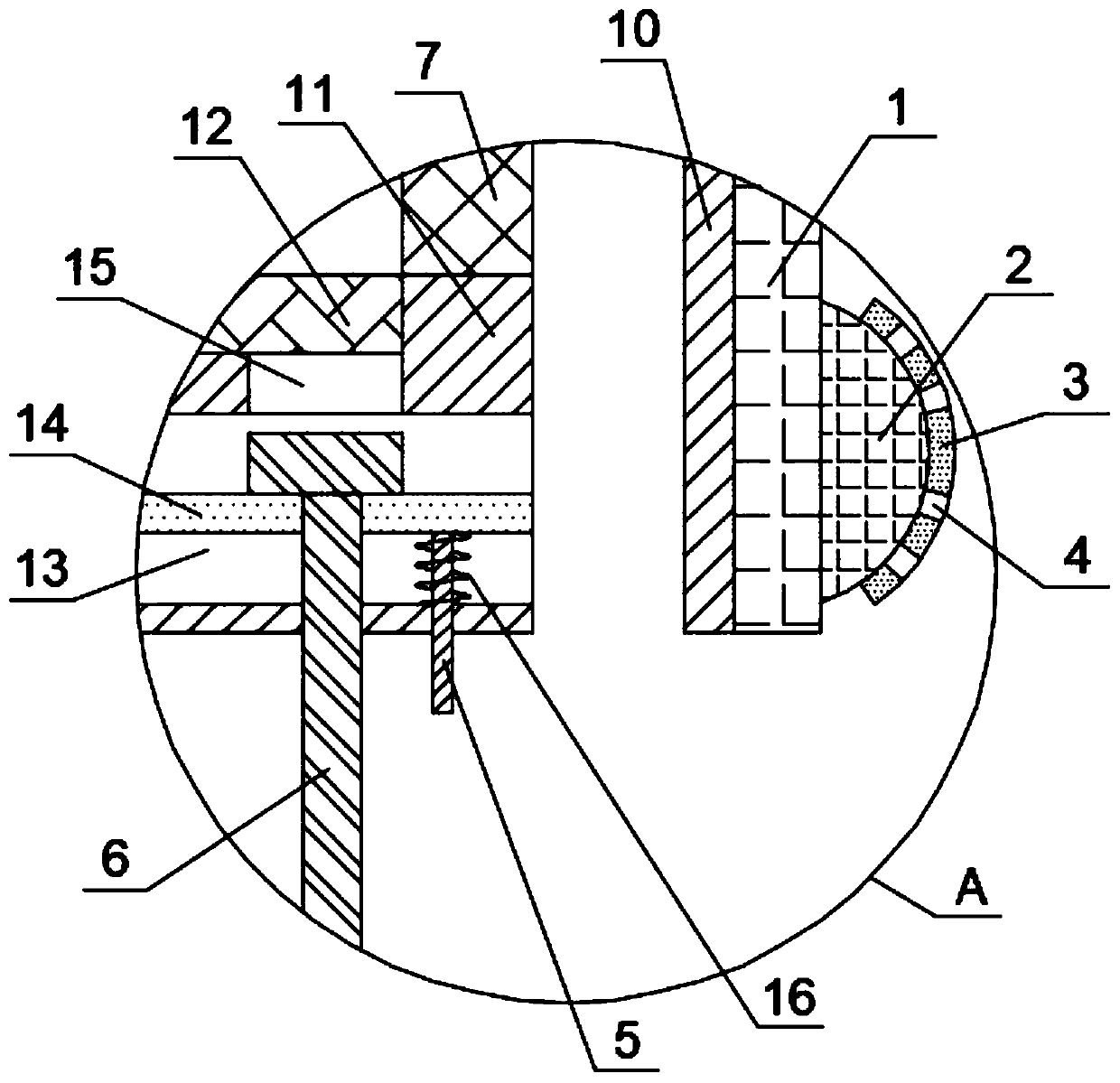

[0034] Example 1, please refer to Figure 1-5 , the present invention provides a technical solution: a low-frequency transformer with a built-in shielding layer, including a shell 1 with a bottom opening structure, a skeleton 7, a coil 9, pins 6 and an iron core 8, and the inner side of the shell 1 is fixedly connected with a shielding layer 10, The inner side of the shielding layer 10 is fixedly connected with a skeleton 7, and the inner side of the skeleton 7 is fixedly connected with an iron core 8, the outer surface of the iron core 8 is provided with a coil 9, and the bottom of the skeleton 7 is fixedly connected with two sets of mounting brackets with concave tops. plate 11, the inside of the top of the mounting plate 11 is fixedly connected with a conductive sheet 12, the inside of the mounting plate 11 is provided with a chute 13, and the inside of the mounting plate 11 is located above the chute 13 to provide a plurality of sets of limiting grooves 15, chute 13 There ...

Embodiment 2

[0035] Embodiment two, such as image 3 and Figure 5 As shown, the outer end surface of the housing 1 is fixedly connected with multiple sets of heat dissipation convex fins 2 with a hemispherical cross-section. The groove 4 and the setting of the heat dissipation groove 4 reduce the resistance of the flexible pad 3 to the heat dissipation of the heat dissipation convex fin 2. The flexible pad 3 is made of organic silicon material. The anti-shock performance improves the anti-seismic performance of low-frequency transformers. At the same time, organic silicon products have good electrical insulation properties, and have certain voltage resistance, arc resistance and corona resistance performance, so that low-frequency transformers have certain anti-arc capabilities. .

Embodiment 3

[0036] Embodiment three, such as figure 2 As shown, the shell 1 and the heat dissipation fins 2 are made of aluminum nitride ceramics, the bottom of the mounting plate 11 is flush with the bottom of the shell 1 in the horizontal direction, and the contact area with the outside air is increased through the heat dissipation fins 2, improving the The heat dissipation effect of the low-frequency transformer is improved, and the heat dissipation convex fin 2 and the shell 1 are made of aluminum nitride ceramic material, and the heat generated by the low-frequency transformer is discharged outward by using the good thermal conductivity of the aluminum nitride ceramic material, thereby improving the performance of the transformer. For the heat dissipation performance of the low-frequency transformer, the bottom of the mounting plate 11 is flush with the bottom of the housing 1 in the horizontal direction, ensuring that the bottom of the housing 1 can be attached to the top of the PBC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com