Anti-electric-arc flame-retardant mixture and manufacturing method thereof

A production method and technology of mixture, applied in protective clothing, clothing, yarn and other directions, can solve the problems of not explaining the role of fiber relationship, no public research data, etc., and achieve the effect of improving wearing body feeling, good toughness, and high arc resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

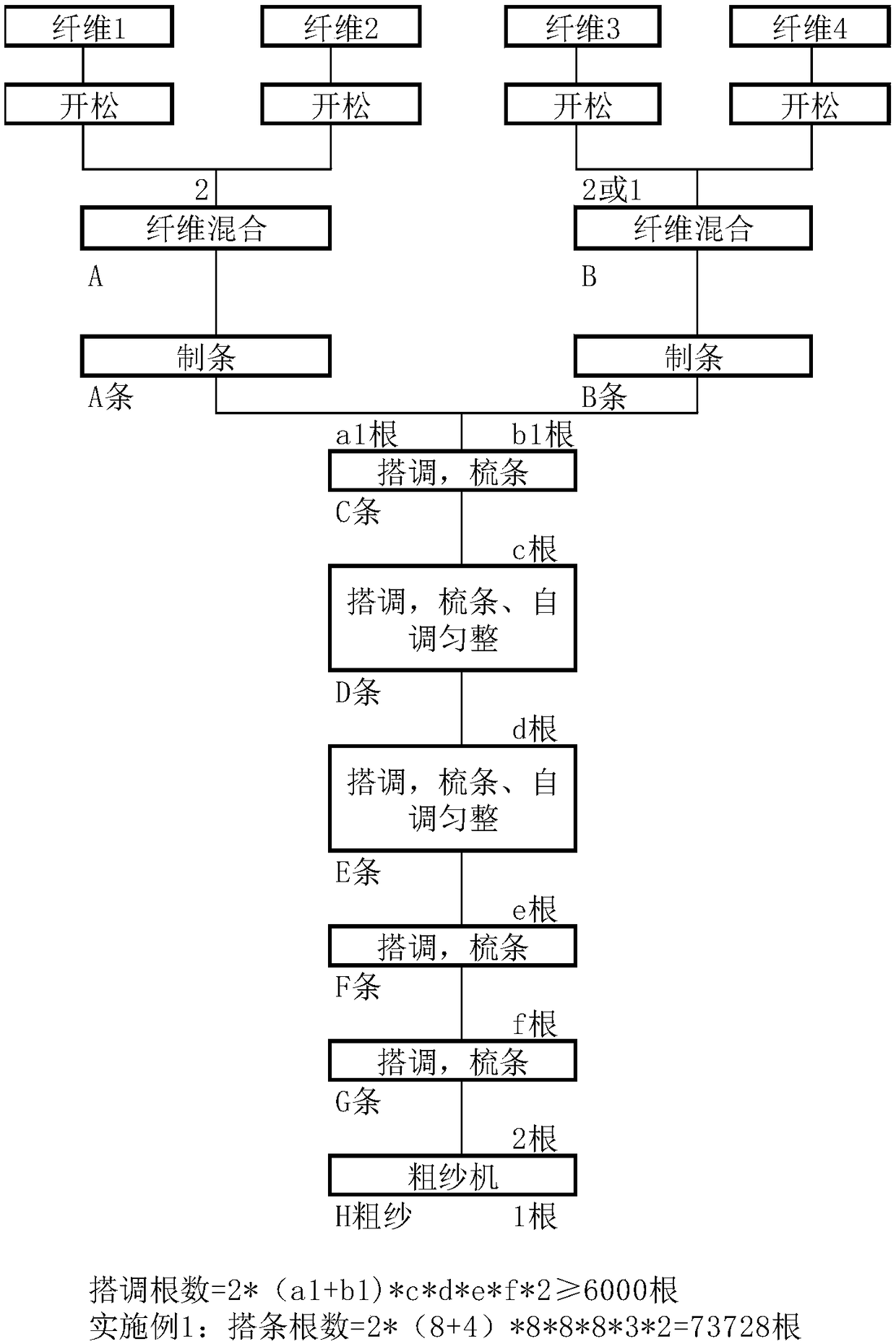

Method used

Image

Examples

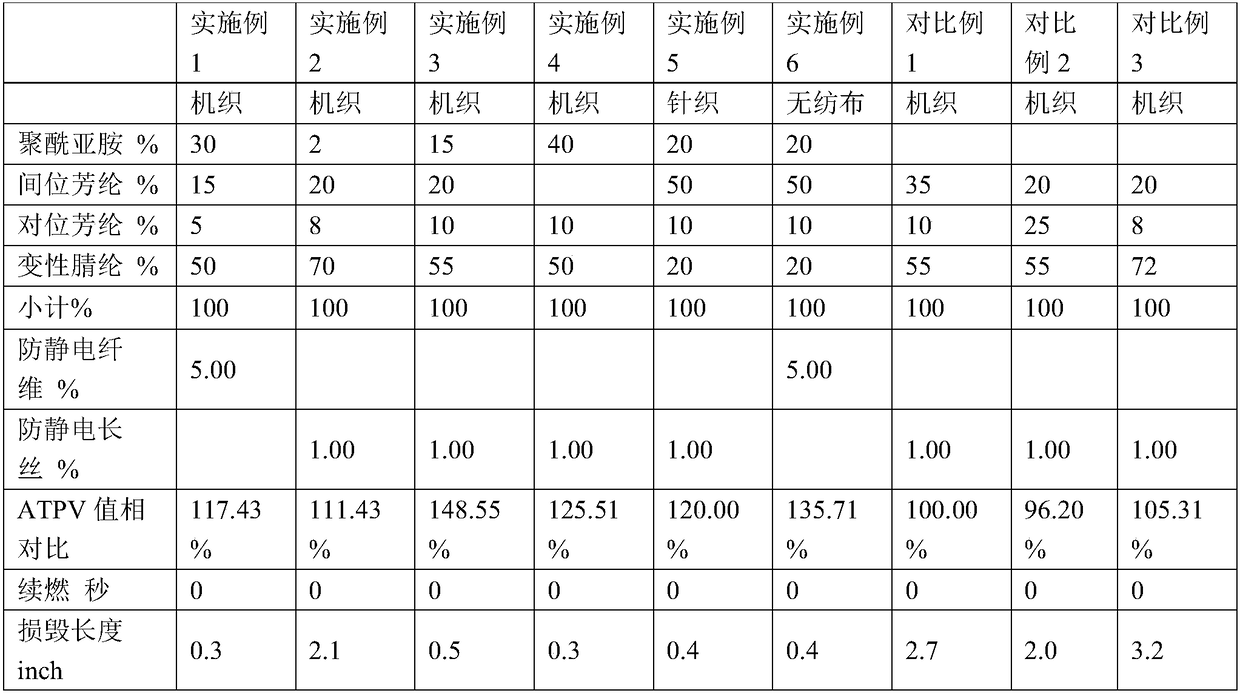

Embodiment 1

[0042] An anti-arc and flame-retardant mixture composed of polyimide, meta-aramid, para-aramid, denatured acrylic and antistatic fibers; polyimide, meta-aramid, para-aramid, denatured acrylic The total mass is recorded as A; the percentages of polyimide, meta-aramid, para-aramid and modified acrylic fiber in A are respectively, polyimide: 30%; meta-aramid: 15%; para-aramid Polyester: 5%; Modacrylic: 50%. The antistatic fiber accounts for 5% of A.

Embodiment 2

[0044] An anti-arc and flame-retardant mixture composed of polyimide, meta-aramid, para-aramid, denatured acrylic and antistatic filament; polyimide, meta-aramid, para-aramid, denatured acrylic The sum of the mass is recorded as A; the percentages of polyimide, meta-aramid, para-aramid and modified acrylic fiber in A are respectively, polyimide: 2%; meta-aramid: 20%; para-aramid Aramid: 8%; Modacrylic: 70%. The antistatic filament accounts for 1% of A.

Embodiment 3

[0046] An anti-arc and flame-retardant mixture composed of polyimide, meta-aramid, para-aramid, denatured acrylic and antistatic filament; polyimide, meta-aramid, para-aramid, denatured acrylic The sum of the mass is recorded as A; the percentages of polyimide, meta-aramid, para-aramid and modified acrylic fiber in A are respectively, polyimide: 15%; meta-aramid: 20%; para-aramid Aramid: 10%; Modacrylic: 55%. The antistatic filament accounts for 1% of A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com