High-brightness extinction, light-storing, luminescent glass and method of producing the same

A technology of luminous glass and high brightness, applied in the fields of luminous glass and its manufacture, high brightness light absorption and light storage, can solve the problems of low brightness and short afterglow time, and achieve the effect of high brightness, long afterglow time and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

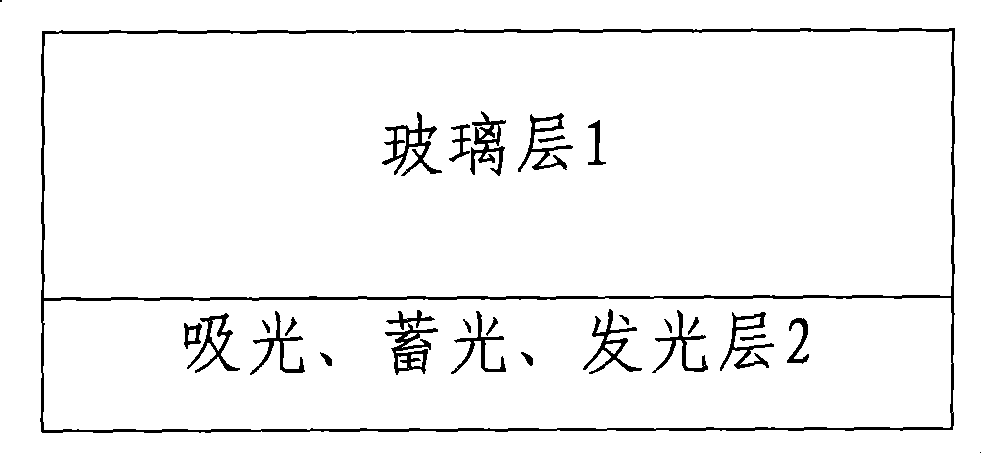

[0025] like figure 1 As shown, the high-brightness light-absorbing, light-storing, and luminescent glass of this embodiment includes a glass layer 1 and a light-absorbing, light-storing, and light-emitting layer 2, wherein,

[0026] The glass layer 1 accounts for 60-80% of the total weight, and its material is glass powder;

[0027] The light-absorbing, light-storing and luminescent layer 2 accounts for 20-40% of the total weight, and its material is light-absorbing, light-storing, luminescent powder and glass powder.

[0028] In the high-brightness light-absorbing, light-storing, and luminescent glass provided by the present invention, the thickness of the glass layer 1 can account for one-half to two-thirds of the total thickness of the product, and the thickness of the light-absorbing, light-storing, and light-emitting layer 2 can account for one-third of the total thickness of the product. One-half to one-half. The present invention has the following advantages:

[0029...

Embodiment 2

[0036] On the basis of the first embodiment, the luminescent powder is preferably rare earth strontium aluminate series high-brightness luminescent powder.

Embodiment 3

[0038] On the basis of Example 1, the components (by weight percentage) of light absorption, light storage and light emitting layer 2 are:

[0039] Glass powder 30~80%

[0040] Polished dry grain 10~20%

[0041] Boric acid 8~10%

[0042] Sodium carbonate 10~20%

[0043] Strontium aluminate 5-16%.

[0044] During specific implementation, the components of light-absorbing, light-storing, and light-emitting layers 2 are exemplified as follows:

[0045] (1) 67% glass powder, 10% polished dry grain, 8% boric acid, 10% sodium carbonate, 5% strontium aluminate;

[0046] (2) 46% glass powder, 20% polished dry grain, 9% boric acid, 15% sodium carbonate, 10% strontium aluminate;

[0047] (3) 65% glass powder, 10% polished dry grain, 10% boric acid, 10% sodium carbonate, 5% strontium aluminate;

[0048] (4) 52% glass powder, 10% polished dry grain, 8% boric acid, 20% sodium carbonate, 10% strontium aluminate;

[0049] (5) Glass powder 56%, polished dry grain 10%, boric acid 8%, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com