Fireproof silicone rubber composite material and preparation method thereof

A technology of composite materials and silicone rubber, applied in the direction of rubber layered products, chemical instruments and methods, lamination, etc., can solve the problems of large specific gravity, thick products, short fire resistance time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

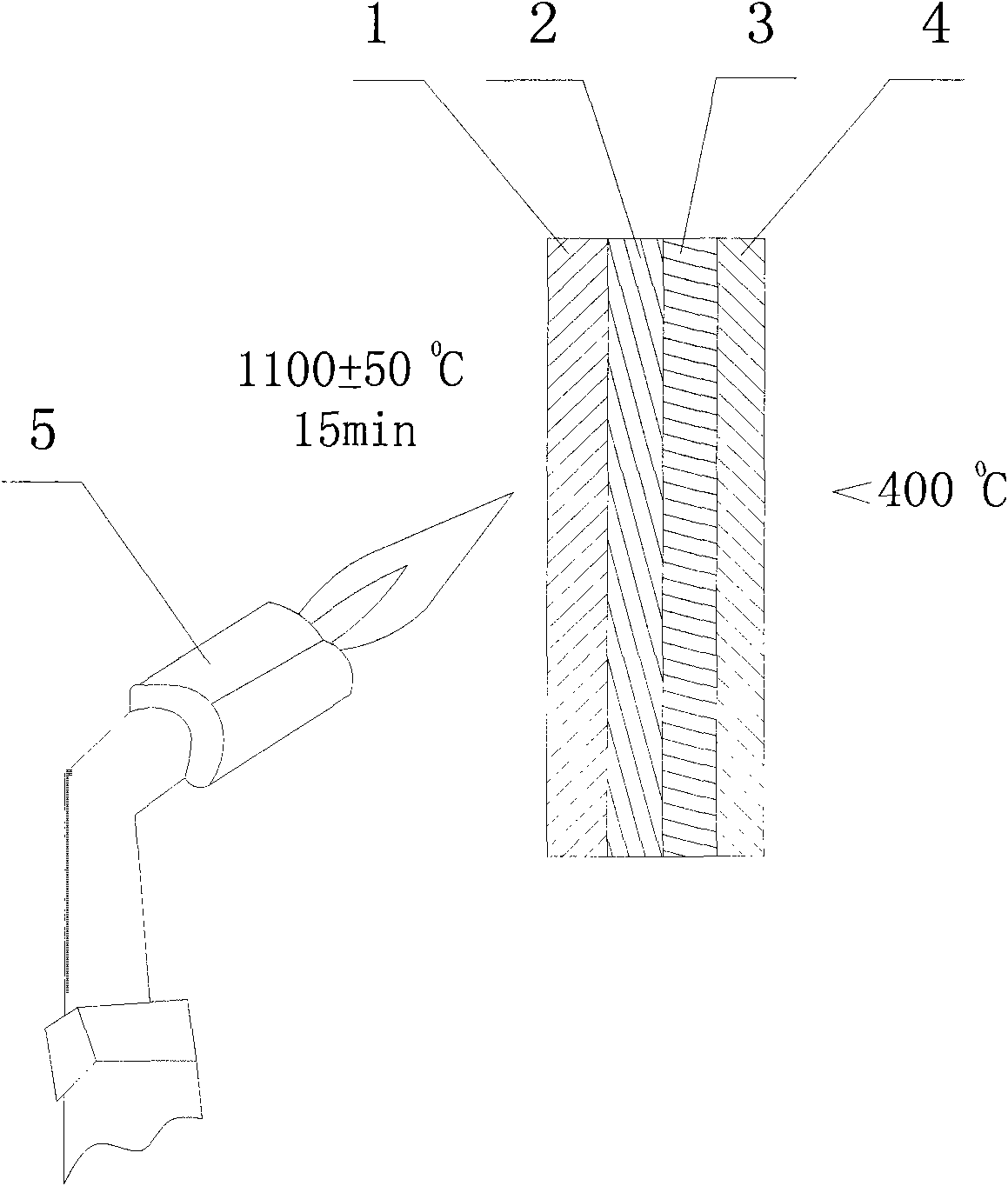

[0058] Fireproof silicone rubber composite material, which is composed of silicone rubber fireproof isolation layer 1, silicone rubber flame retardant and cooling layer 2, silicone rubber anti-ablation layer 3, and body silicone rubber layer 4. The flame-retardant cooling layer, the silicone rubber anti-ablation layer, and the body silicone rubber layer are arranged in sequence from outside to inside.

[0059] The preparation method of above-mentioned fireproof silicone rubber composite material, it comprises the steps:

[0060] 1. Preparation of semi-finished silicone rubber fireproof insulation layer:

[0061] The material of the silicone rubber fireproof isolation layer is prepared from matrix, fireproof filler, reinforcing material, crosslinking agent, catalyst and adhesive raw materials. The parts by weight of each raw material are: 100 parts of matrix, 100 parts of fireproof filler, reinforcing material 50 parts, 3 parts of crosslinking agent, 0.2 part of catalyst, 1 pa...

Embodiment 2

[0088] Fireproof silicone rubber composite material, which is composed of silicone rubber fireproof isolation layer 1, silicone rubber flame retardant and cooling layer 2, silicone rubber anti-ablation layer 3, and body silicone rubber layer 4. The flame-retardant cooling layer, the silicone rubber anti-ablation layer, and the body silicone rubber layer are arranged in sequence from outside to inside.

[0089] The preparation method of above-mentioned fireproof silicone rubber composite material, it comprises the steps:

[0090] 1. Preparation of semi-finished silicone rubber fireproof insulation layer:

[0091] The material of the silicone rubber fireproof isolation layer is prepared from matrix, fireproof filler, reinforcing material, crosslinking agent, catalyst and adhesive raw materials. The parts by weight of each raw material are: 100 parts of matrix, 200 parts of fireproof filler, reinforcing material 70 parts, 5 parts of crosslinking agent, 0.3 parts of catalyst, 50 ...

Embodiment 3

[0121] Fireproof silicone rubber composite material, which is composed of silicone rubber fireproof isolation layer 1, silicone rubber flame retardant and cooling layer 2, silicone rubber anti-ablation layer 3, and body silicone rubber layer 4. The flame-retardant cooling layer, the silicone rubber anti-ablation layer, and the body silicone rubber layer are arranged in sequence from outside to inside.

[0122] The preparation method of above-mentioned fireproof silicone rubber composite material, it comprises the steps:

[0123] 1. Preparation of semi-finished silicone rubber fireproof insulation layer:

[0124] The material of the silicone rubber fireproof isolation layer is prepared from matrix, fireproof filler, reinforcing material, crosslinking agent, catalyst and adhesive raw materials. The parts by weight of each raw material are: 100 parts of matrix, 300 parts of fireproof filler, reinforcing material 100 parts, 8 parts of crosslinking agent, 0.4 parts of catalyst, 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com