A kind of flame-retardant and moisture-proof super-strength particleboard and its preparation method

A technology of particleboard and shavings, which is applied in the field of flame-retardant and moisture-proof super-strength particleboard and its preparation. It can solve the problems of insufficient strength, easy deformation, and water-absorbing swelling of the particleboard, and achieve uniform cross-sectional density distribution, reduced bonding strength, and good water resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

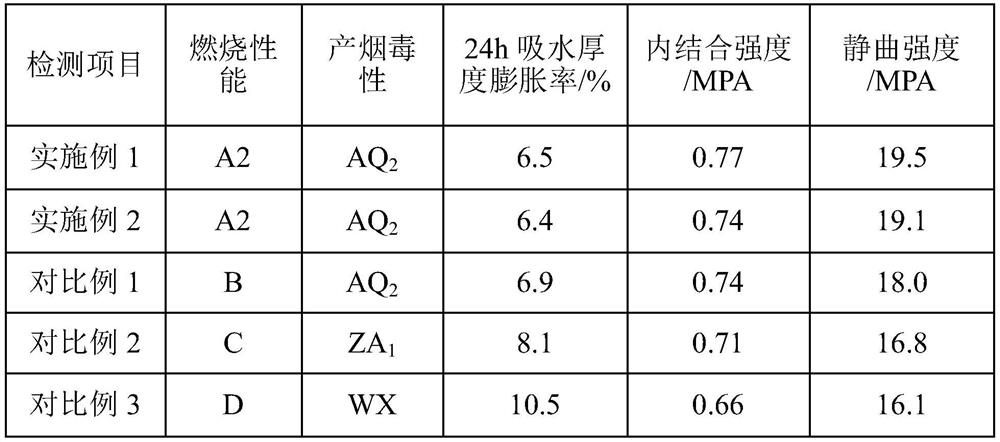

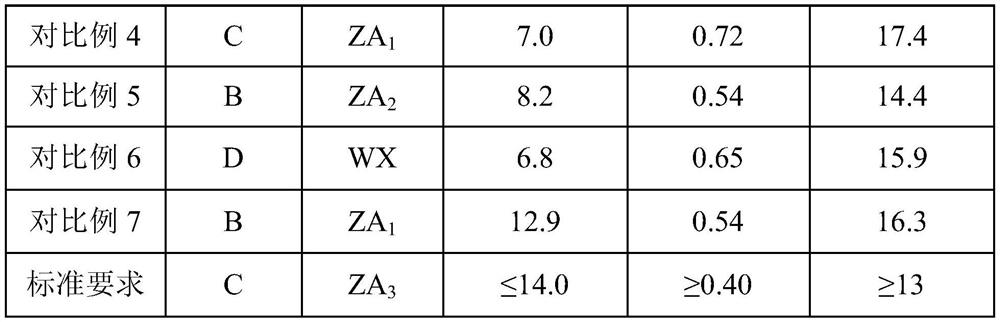

Examples

Embodiment 1

[0028] A method for preparing a flame-retardant and moisture-proof super-strength particleboard, comprising the following steps:

[0029] (1) Chip the eucalyptus wood raw material to obtain wood chips, screen the wood chips, and screen out wood chips with a length of 40-80 mm and a length of less than 40 mm, and use a ring-type long planer for wood chips with a length of 40-80 mm Process into wood shavings, and process wood chips of different sizes into wood shavings with ordinary shaving machines, and wood chips with a length of less than 40mm are processed into wood shavings with ordinary shaving machines;

[0030] A secondary vibrating screen is installed at the wood shaving outlet of the ring-type long wood planer. The apertures of the secondary vibrating screens are 20mm×60mm and 10mm×40mm respectively, and the super large shavings, large shavings, coarse shavings, and For fine shavings, the length of super large shavings is 60-80mm, the length of large shavings is 40-59m...

Embodiment 2

[0045] A method for preparing a flame-retardant and moisture-proof super-strength particleboard, comprising the following steps:

[0046] (1) Chip the eucalyptus wood raw material to obtain wood chips, screen the wood chips, and screen out wood chips with a length of 40-80 mm and a length of less than 40 mm, and use a ring-type long planer for wood chips with a length of 40-80 mm Process into wood shavings, and process wood chips of different sizes into wood shavings with ordinary shaving machines, and wood chips with a length of less than 40mm are processed into wood shavings with ordinary shaving machines;

[0047] A secondary vibrating screen is installed at the wood shaving outlet of the ring-type long wood planer. The apertures of the secondary vibrating screens are 20mm×60mm and 10mm×40mm respectively, and the super large shavings, large shavings, coarse shavings, and For fine shavings, the length of super large shavings is 60-80mm, the length of large shavings is 40-59m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com