Oxadiargyl and butachlor aqueous emulsion and preparation method thereof

A technology of oxadiazon and butachlor, applied in the field of pesticides, can solve problems such as toxicity, easy explosion, flammability, etc., and achieve the effects of reducing use cost, toxicity and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 5kg of propargyl oxadiazone and 30kg of butachlor, xylene 10kg, emulsifier ethylene oxide propylene block copolymer 8kg, thickener xanthan gum 0.25kg, antifreeze agent ethylene glycol 0.1kg, defoamer 0.1kg, deionized water make up 100kg. Its preparation method:

[0027] (1) Preparation of oil phase

[0028] Put propargyl oxadiazone, butachlor, xylene, ethylene oxide propylene block copolymer into the oil phase preparation kettle, stir, mix and dissolve to make it a uniform oil phase;

[0029] (2) Preparation of water phase

[0030] Put deionized water, ethylene glycol, silicone defoamer, etc. into the water phase preparation kettle, stir and mix to make a uniform water phase;

[0031] (3) Preparation of propargyl oxadiazone and butachlor aqueous emulsion: put the prepared oil phase and water phase into the aqueous emulsion preparation kettle equipped with a high-speed shearing machine, at a speed of 2000-20000 rpm The high-speed shearing time under the conditi...

Embodiment 2

[0033] Take by weighing 10kg propargyl oxadiazone former medicine and 35kg butachlor former medicine, xylene 5kg, solvent naphtha 5kg, emulsifier epoxy ethylene oxide propylene block copolymer 10kg, thickener magnesium aluminum silicate 0.3kg, 1.2kg of antifreeze ethylene glycol, 0.1kg of silicone defoamer, and 100kg of deionized water. Its preparation method:

[0034] (1) Preparation of oil phase

[0035] Put propargyl oxadiazone, butachlor, xylene, ethylene oxide propylene block copolymer into the oil phase preparation kettle, stir, mix and dissolve to make it a uniform oil phase;

[0036] (2) Preparation of water phase

[0037] Put deionized water, ethylene glycol, silicone defoamer, etc. into the water phase preparation kettle, stir and mix to make a uniform water phase;

[0038] (3) Preparation of propargyl oxadiazone and butachlor aqueous emulsion: put the prepared oil phase and water phase into the aqueous emulsion preparation kettle equipped with a high-speed sheari...

Embodiment example

[0040] 1. Pharmacy

[0041] 1.1 Test drug

[0042] 5% propargyl oxadiazone + 30% butachlor aqueous emulsion, produced by Anhui National Pesticide Formulation Engineering Technology Center and Anhui Kelihua Chemical Co., Ltd.

[0043] 1.2 Control drug

[0044] 5% propargyl oxadiazone EC (Shandong Dongtai Agrochemical Co., Ltd.) and 30% butachlor EC (Inner Mongolia Hongyu Pesticide Co., Ltd.).

[0045] In addition, manual weeding and blank control treatments were set up.

[0046] 1.3 Experimental Design of Drugs to be Tested

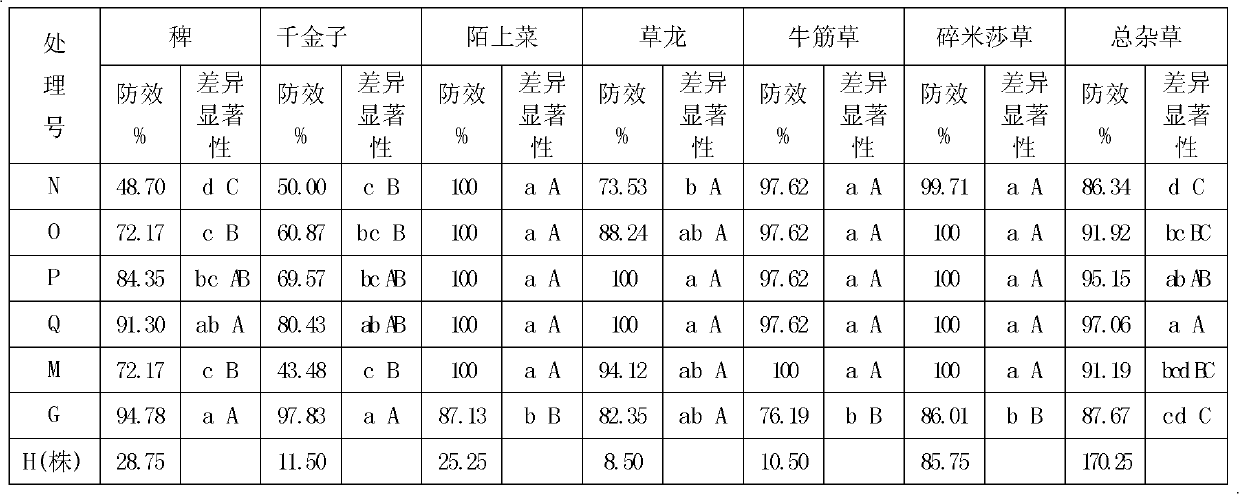

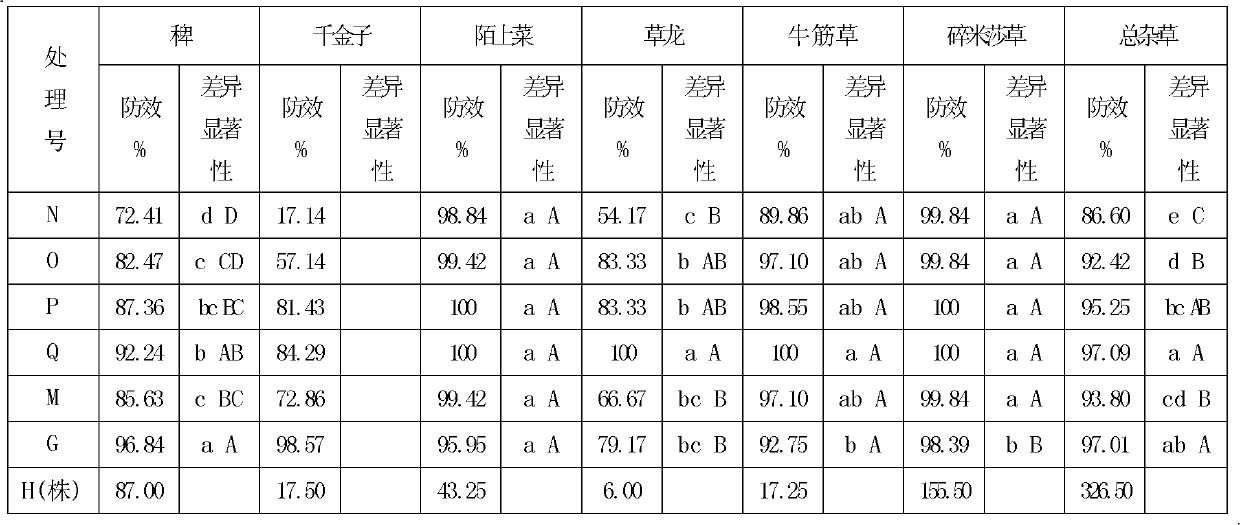

[0047] Table 1 Experimental design of test agents

[0048]

[0049] 2 community arrangement

[0050] 2.1 Arrangement of plots (other letter codes refer to other experimental treatments)

[0051] A

N

O

E

K

S

G

H

V

B

L

P

B

M

P

F

J

T

E

I

U

A

N

Q

C

L

Q

G

I

U

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com