Water-based cleaning agent for magnesium aluminum alloy and preparation method of water-based cleaning agent

A water-based cleaning agent, magnesium-aluminum alloy technology, applied in the field of surface treatment of metal products, can solve the problems of many residues, the cleaning rate cannot reach high efficiency, and the cleaning effect is not very good, and achieves high cleaning rate, simple operation, and preparation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

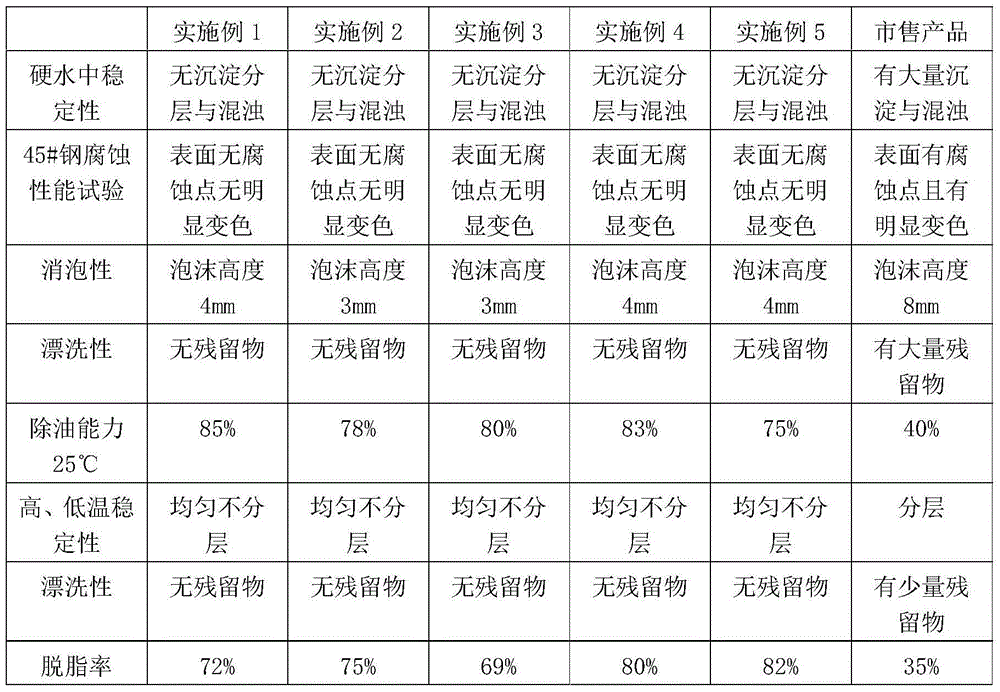

Examples

Embodiment 1

[0023] A magnesium-aluminum alloy water-based cleaning agent, the raw materials include in parts by weight: 3 parts of stearic acid, 2 parts of lecithin, 1 part of sodium polyacrylate, 4 parts of propylene glycol butyl ether, 3 parts of sodium xylenesulfonate, dimethyl 2 parts of base silicone oil, 1 part of alkyl alcohol amide, 2 parts of sodium metasilicate, 1 part of benzotriazole, 3 parts of sodium allyl sulfonate, 4 parts of diacetone acrylamide, dimethylaminoethyl acrylate 3 parts, 29 parts of defoamer, 15 parts of deionized water.

[0024] The defoamer is octanol, and the alkanolamide is lauroyl monoethanolamine.

[0025] The preparation method of the above-mentioned magnesium-aluminum alloy water-based cleaning agent comprises the following steps:

[0026] Step 1, add stearic acid, lecithin, sodium polyacrylate, propylene glycol butyl ether and diacetone acrylamide into deionized water, program temperature rise to 70°C (10°C every half hour), stir well, let cool, Mix...

Embodiment 2

[0031] A magnesium-aluminum alloy water-based cleaning agent, raw materials include in parts by weight: 5 parts of stearic acid, 4 parts of lecithin, 3 parts of sodium polyacrylate, 5 parts of propylene glycol butyl ether, 4 parts of sodium xylene sulfonate, dimethyl 3 parts of base silicone oil, 2 parts of alkyl alcohol amide, 3 parts of sodium metasilicate, 2 parts of benzotriazole, 4 parts of sodium allyl sulfonate, 5 parts of diacetone acrylamide, dimethylaminoethyl acrylate 5 parts, 4 parts of defoamer, 18 parts of deionized water.

[0032] The defoamer is mineral oil, and the alkanolamide is oleoyl diethanolamine.

[0033] The preparation method of the above-mentioned magnesium-aluminum alloy water-based cleaning agent comprises the following steps:

[0034] Step 1, add stearic acid, lecithin, sodium polyacrylate, propylene glycol butyl ether and diacetone acrylamide into deionized water, program temperature rise to 80°C (10°C every half hour), stir well, let cool, Mix...

Embodiment 3

[0039] A magnesium-aluminum alloy water-based cleaning agent, the raw materials include in parts by weight: 7 parts of stearic acid, 6 parts of lecithin, 5 parts of sodium polyacrylate, 8 parts of propylene glycol butyl ether, 7 parts of sodium xylene sulfonate, dimethyl 6 parts of base silicone oil, 4 parts of alkanolamide, 5 parts of sodium metasilicate, 4 parts of benzotriazole, 8 parts of sodium allyl sulfonate, 7 parts of diacetone acrylamide, dimethylaminoethyl acrylate 9 parts, 7 parts of defoamer, 25 parts of deionized water.

[0040]The defoamer is tributyl phosphate, and the alkanolamide is cocoamide monoethanolamine.

[0041] The preparation method of the above-mentioned magnesium-aluminum alloy water-based cleaning agent comprises the following steps:

[0042] Step 1, add stearic acid, lecithin, sodium polyacrylate, propylene glycol butyl ether and diacetone acrylamide into deionized water, program temperature rise to 70°C (10°C every half hour), stir well, let co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com