Electric vehicle battery

A technology for electric vehicles and batteries, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of immaturity, low safety performance, poor fast charging capability, etc., to achieve no pollution to the environment and good safety. , the effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

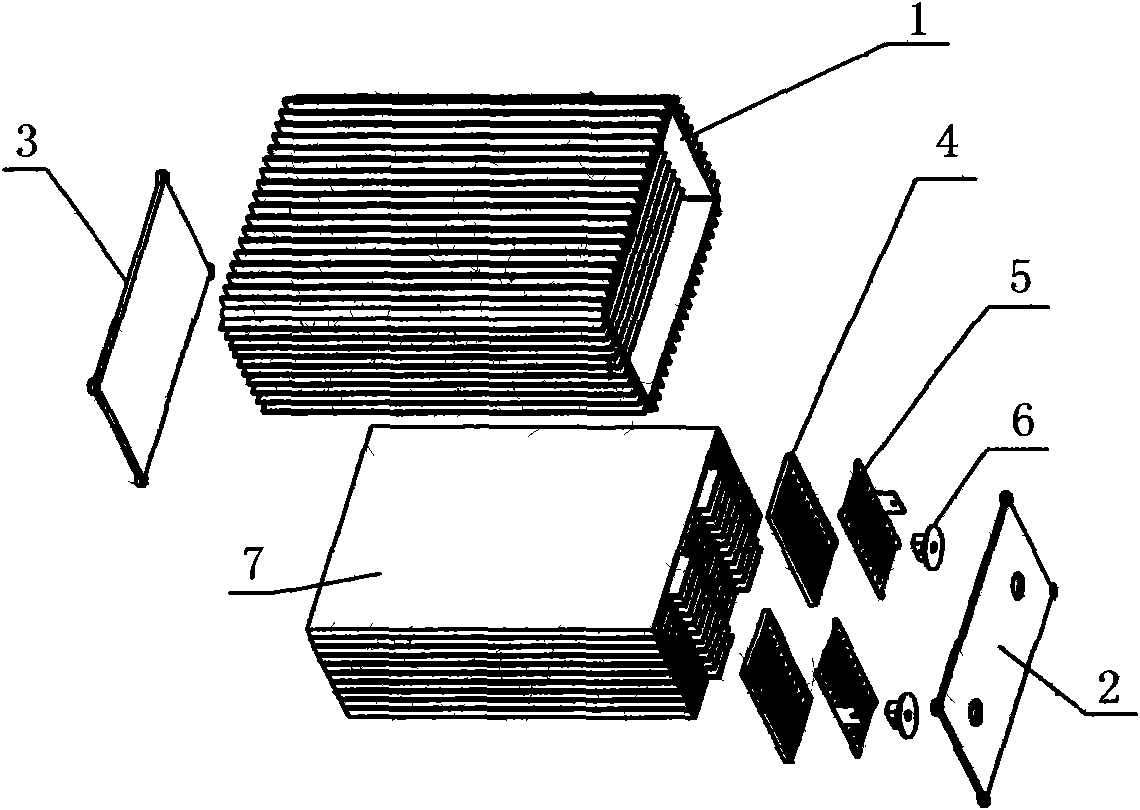

[0013] The electric vehicle battery of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0014] Such as figure 1 As shown, the electric vehicle battery of the present invention includes an aluminum case 1, an upper cover 2 and a lower cover 3, the aluminum case is a square body, the upper cover and the lower cover are respectively installed at two ends of the aluminum case, and the aluminum case is a cavity Body, the outer circumference of the aluminum shell is strip-shaped, which plays the role of structural stability and heat dissipation. There is an aluminum support structure 4 inside the aluminum shell. The aluminum support structure plays a role of structural stability and heat conduction. The cavity in the aluminum shell is divided into ten sub-districts, and ten sheet-shaped soft-packed lithium iron phosphate batteries are placed in each sub-district. 7. The lithium iron phosphate battery is outsourced with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com