Manufacturing process for graphene powder containing charged tetrafluoroethylene-hexafluoropropylene polymer

A technology of hexafluoropropylene and tetrafluoroethylene, which is applied in the production process of tetrafluoroethylene-hexafluoropropylene polymer graphene powder, can solve the problems of affecting anti-corrosion ability, long reaction time, and not easy to remove. Achieve good dispersion, short reaction time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

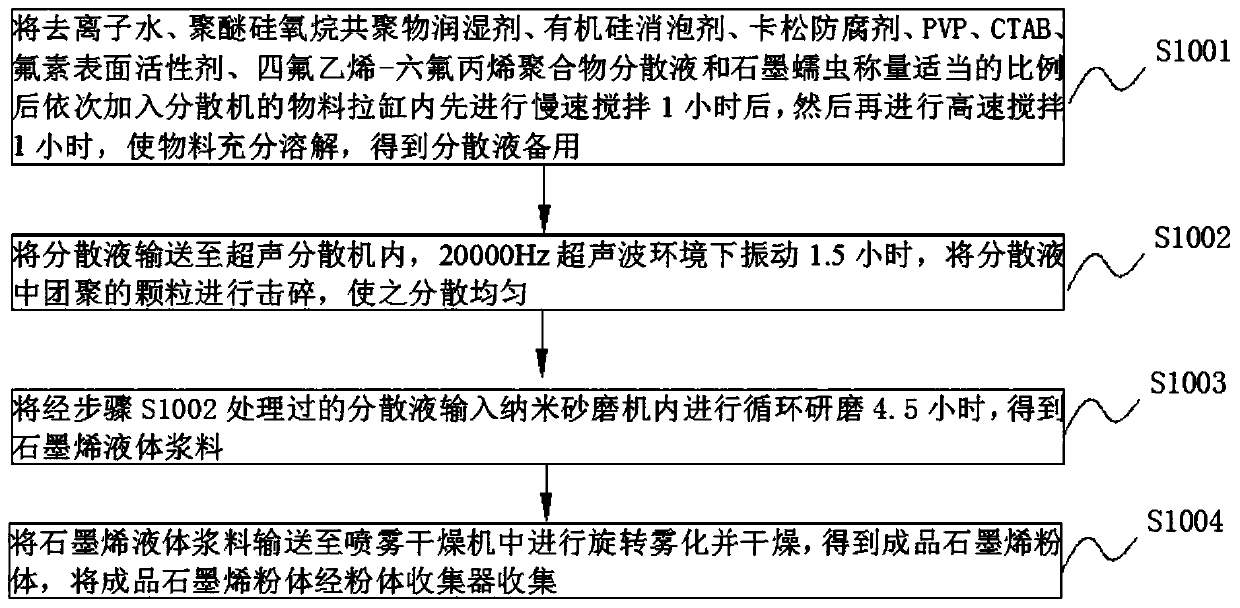

[0025] A preparation process containing charged tetrafluoroethylene-hexafluoropropylene polymer graphene powder, wherein: the preparation process containing charged tetrafluoroethylene-hexafluoropropylene polymer graphene powder comprises the following processing steps:

[0026] S1001: Mix deionized water, polyether siloxane copolymer wetting agent, silicone defoamer, Kathon preservative, PVP, CTAB, fluorine surfactant, tetrafluoroethylene-hexafluoropropylene polymer dispersion After weighing with worm-like graphite, add them in proportion to the material cylinder of the dispersing machine, stir slowly for 1 hour, then stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com